Construction method for synchronous dismantling of lower formwork frame system and peripheral formwork support of retractable post-pouring belt

A construction method and technology of post-pouring tape, applied in the processing of formwork, preparation of building components on site, construction, etc., can solve the problem of affecting construction safety and civilized construction image, affecting the horizontal transportation of materials on the same layer, and the formwork system is inconsistent Timely dismantling and other issues to achieve the effect of reducing rental costs, reducing material backlogs, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

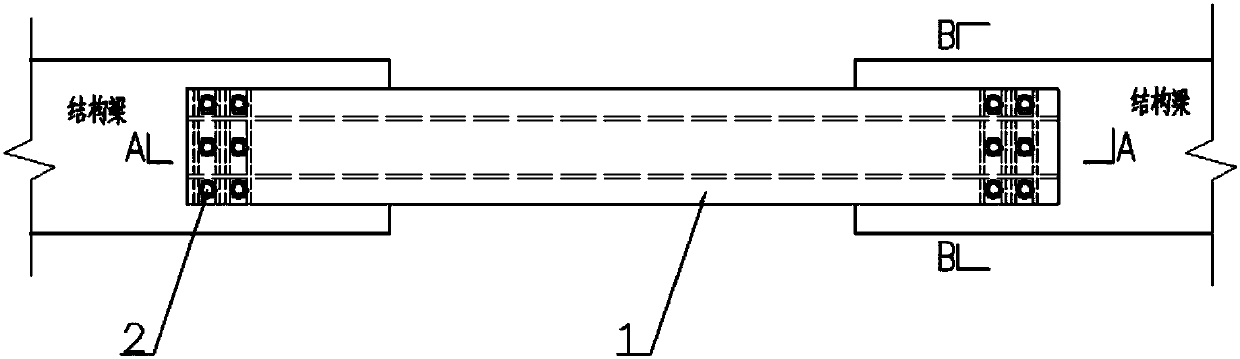

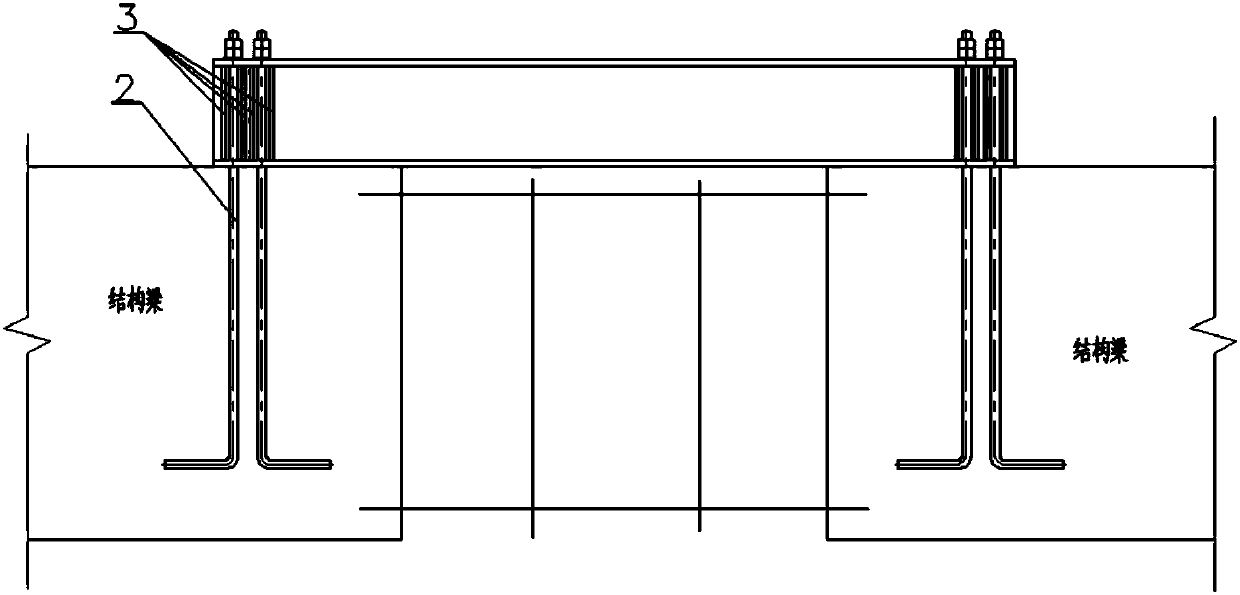

[0029] The construction method of the synchronous removal of the lower formwork system of the telescopic post-cast belt and the surrounding formwork support disclosed in the present invention includes the following steps:

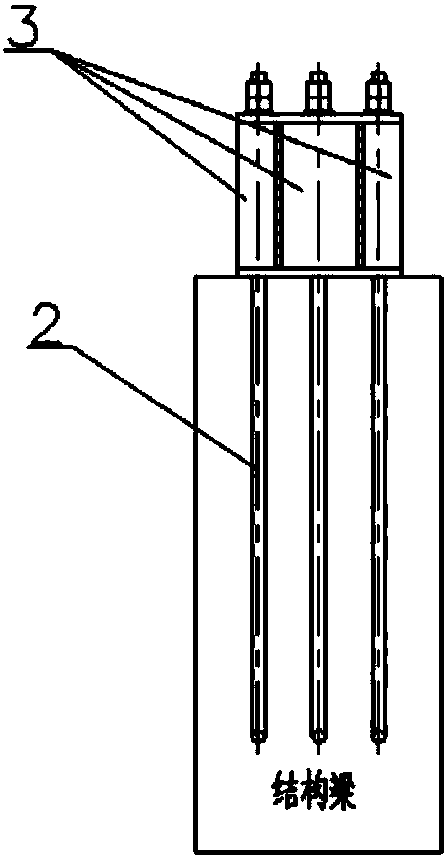

[0030] (1) A steel structure bearing member is installed on the upper part of each post-span cast belt beam;

[0031] (2) Deepening design of load-bearing members and embedded bolts of steel structure, including bolt design of load-bearing members of steel structure;

[0032] In the design of the steel structure bearing member of the present invention, since the post-cast belt is usually placed at 1 / 3 of the beam span, the bending moment and shear force borne by the steel structure bearing member here can be the same as the original structural beam without installation. The value of the internal force when pouring the belt. The load-bearing members of steel structures are checked according to the bending members according to GB50017-2003 "Code for Design of Steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com