Hollow slab bridge and construction method thereof

A hollow slab bridge and hollow slab technology, applied in bridge construction, bridges, buildings, etc., can solve problems such as difficult construction, stress on veneer, and difficulty in ensuring quality, simplify prefabrication and construction technology, and enhance shear force. The effect of the transmission capacity and the force transmission path of the mortise and tenon is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

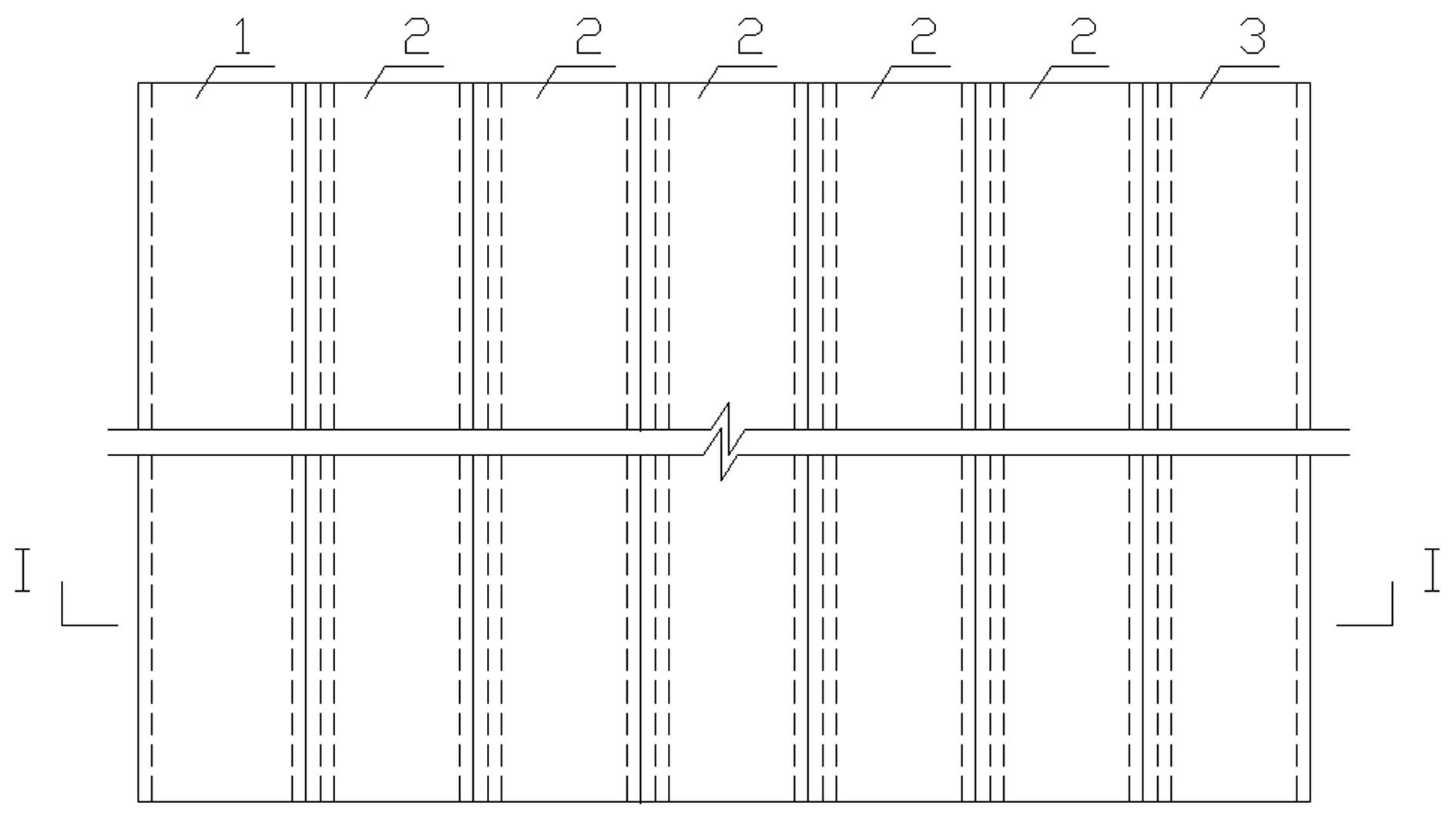

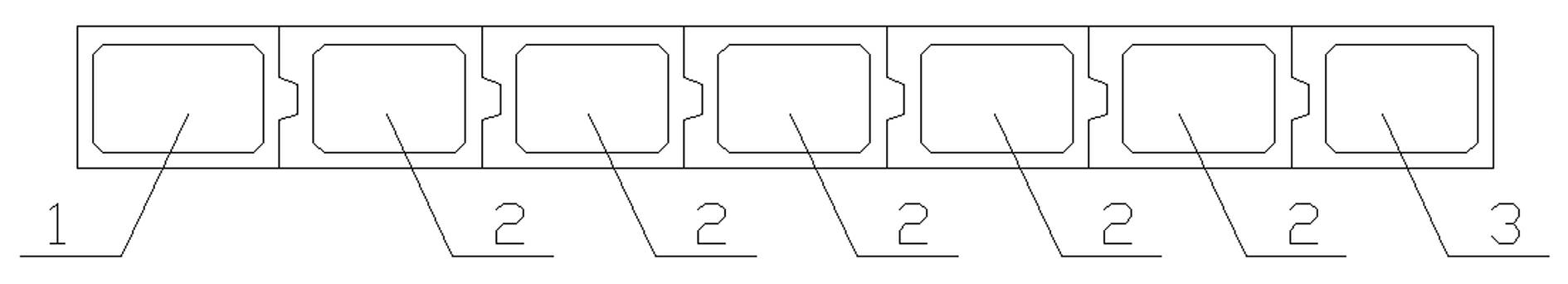

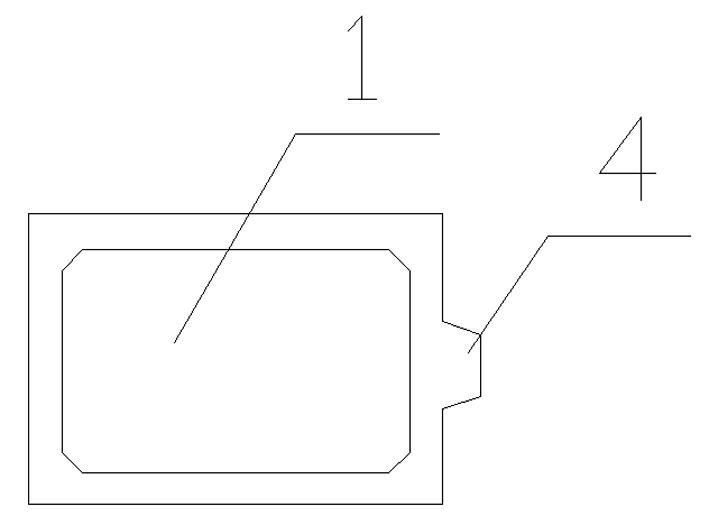

[0024] Example: such as Figure 1-5 As shown, a hollow slab bridge comprises edge hollow plates 1, 3 on both sides and a hollow core plate 2 laid continuously in the middle. The middle part of one side of the hollow core plate 2 is provided with a recessed groove to form a groove 5, and the other side The middle part is provided with a protruding convex strip 4; the lower surface of the groove 5 is an upwardly inclined slope or a plane, the upper surface of the groove 5 is a downwardly inclined slope or a plane, and the lower surface of the matching convex strip 4 is An upwardly inclined slope or plane, the upper surface of the raised strip 4 is a downwardly inclined slope or plane; one side of the outer side hollow plate is a straight edge, and the other side is provided with a groove 5 matching the adjacent hollow plate or rib 4. Steel bars are arranged in the groove 5 and the protruding strip 4, and the ends of the protruding strip 4 and the groove 5 are provided with cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com