Method for producing shoe with air pump device, comprising bellows which is formed in midsole

An air pump and bellows technology is applied in the field of shoe manufacturing to achieve the effects of easy manufacturing, simplified manufacturing and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

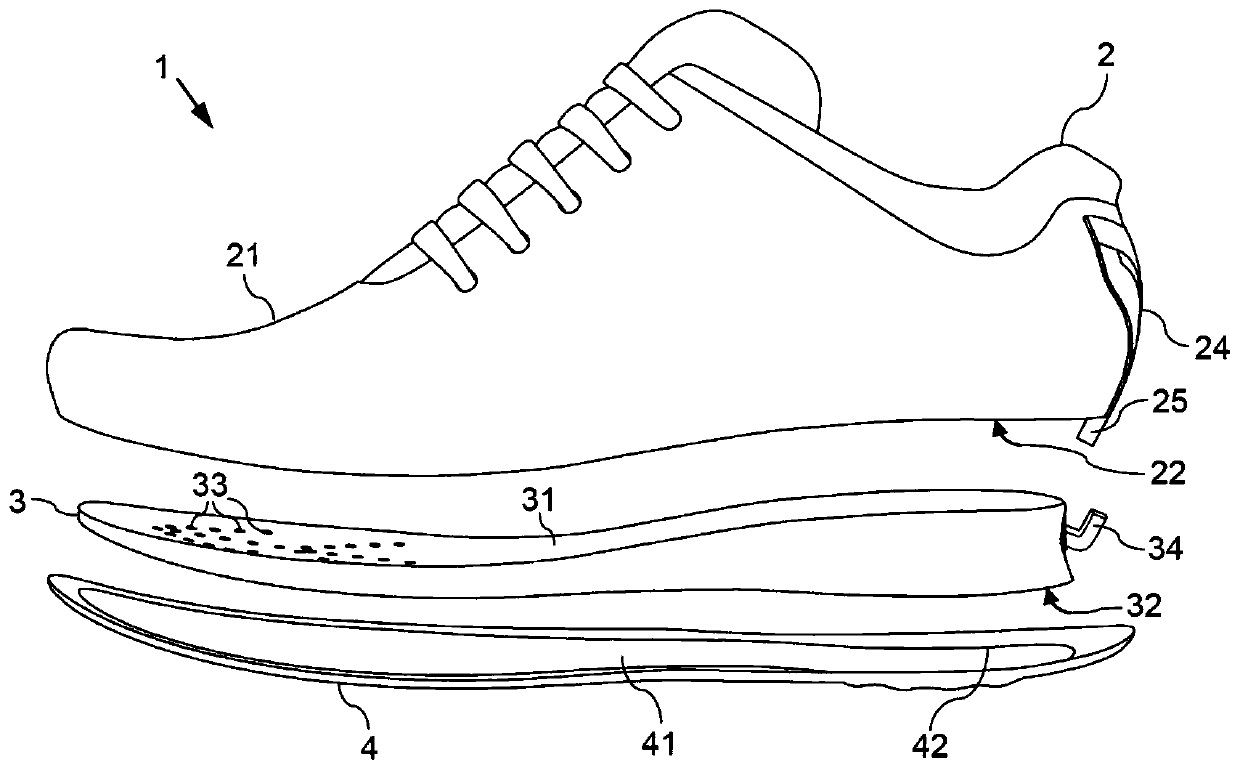

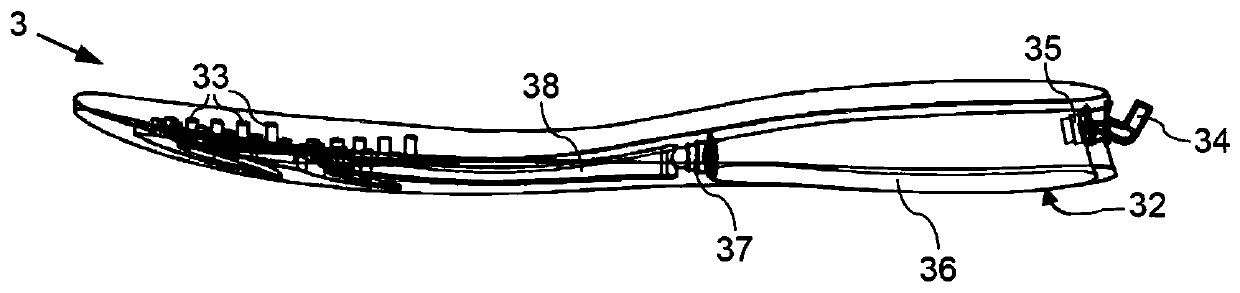

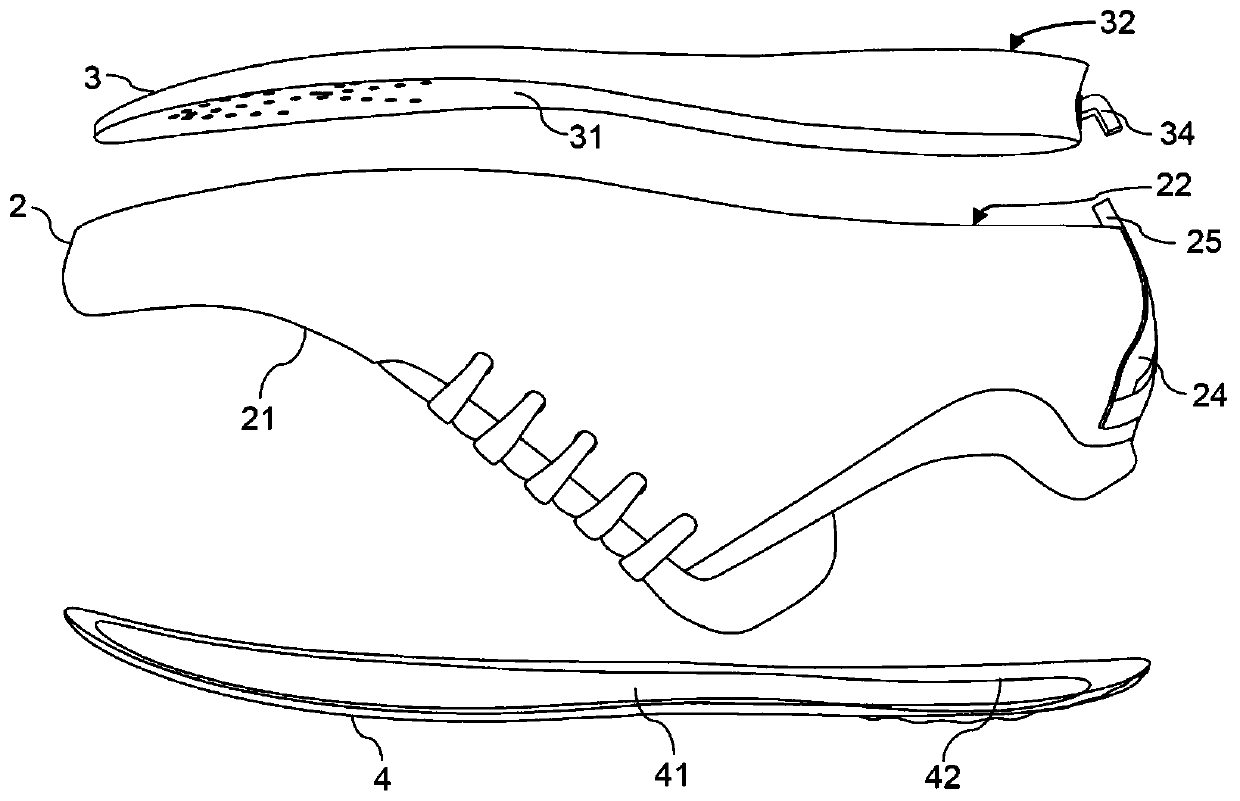

[0039] Now refer to Figures 1 to 4B A first embodiment of the method according to the invention for producing a shoe with an air pumping device arranged in the heel region is described.

[0040] figure 1 A schematic side view is shown of the three basic components used to manufacture the shoe 1 , namely the upper 2 , the midsole 3 and the outsole 4 .

[0041] The upper 2 includes an upper material portion 21 and a sole portion 22 . In this context, sole portion 22 shall refer to the ground-facing portion of the upper and to which the sole structure described below is attached. The upper material portion 21 is the rest of the upper 2 . Sole portion 22 generally includes an insole and may also include additional layers of the shoe, such as an inset sole. In some embodiments, a separate insole can also be dispensed with, eg the leather of the upper can surround the foot starting from the upper material part, eg in the case of eg moccasins.

[0042] The midsole 3 is preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com