Connection component for upright post and cross beam

A technology for connecting components and connecting parts, which is applied to building components, door/window protection devices, fences, etc., can solve the problems of low connection stability and connection strength, many U-shaped joint consumables, and inconvenient installation and disassembly. Strong connection stability and reliability, material saving, stable and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

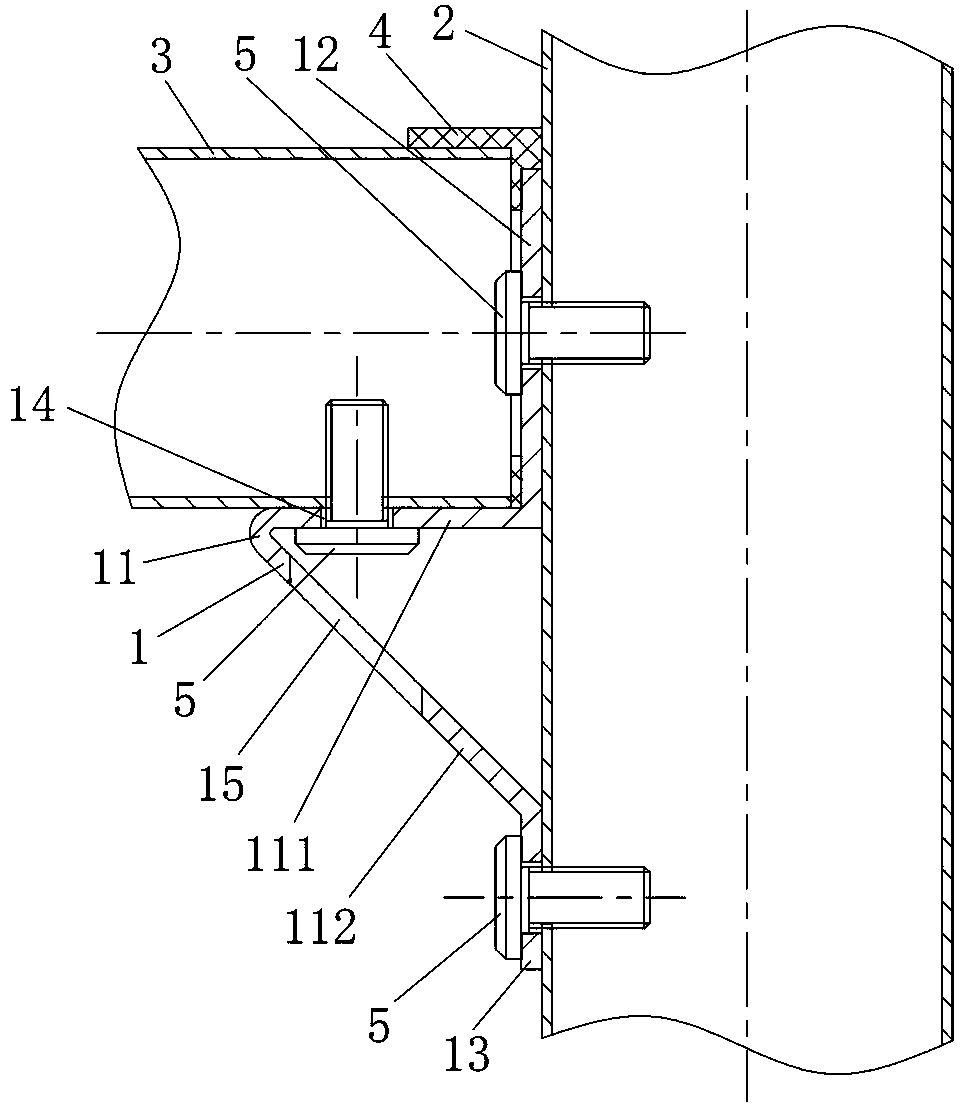

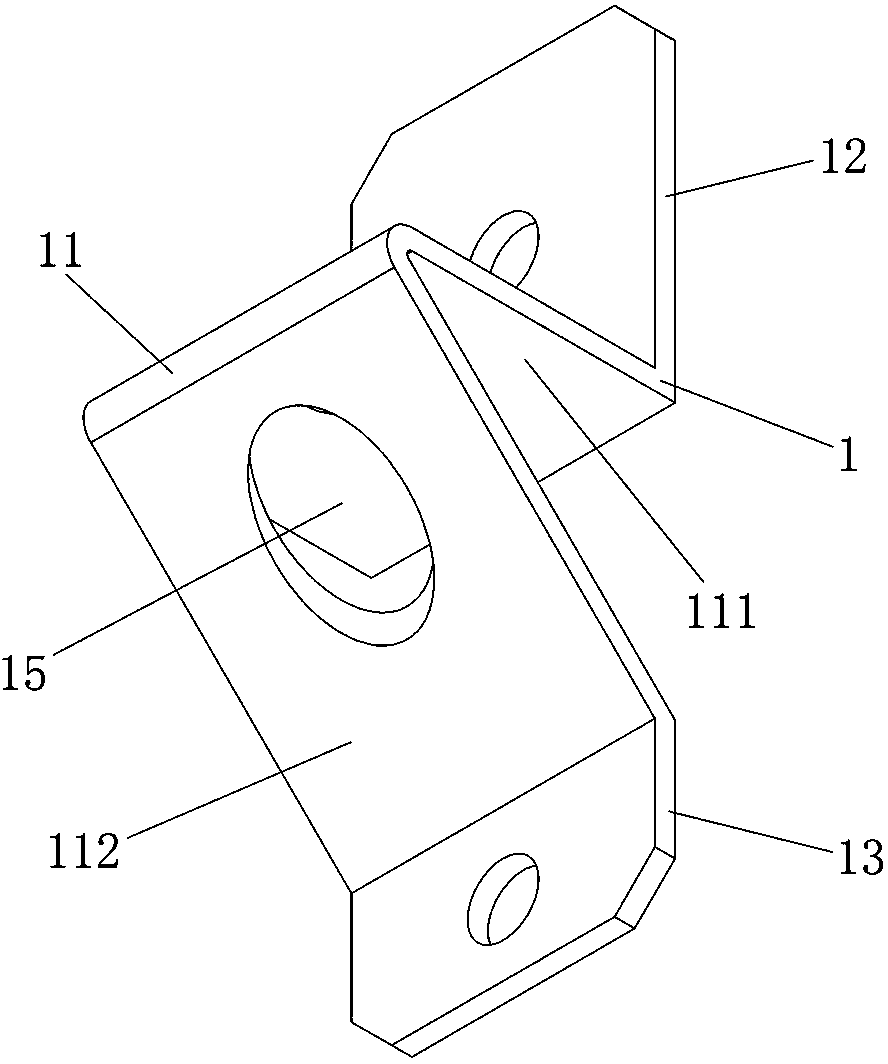

[0020] figure 1 and figure 2 Shown is the first embodiment of the connecting assembly for the column and the crossbeam of the present invention, the connecting assembly of this embodiment includes a connector body 1, and the connector body 1 includes an upper column connecting portion 12, a lower column connecting portion 13 and a connection In the beam connecting portion 11 between the upper column connecting portion 12 and the lower column connecting portion 13, the beam connecting portion 11 includes a supporting edge 111 and an oblique supporting edge 112, and the supporting edge 111 is connected to the lower end of the upper column connecting portion 12 and along the The direction in which the crossbeam 3 is arranged extends outward, and one end of the inclined support side 112 is connected to the upper end of the lower column connection part 13. The inclined support side 112 is arranged obliquely upward and connected with the supporting side 111. After the fastener 5 i...

Embodiment 2

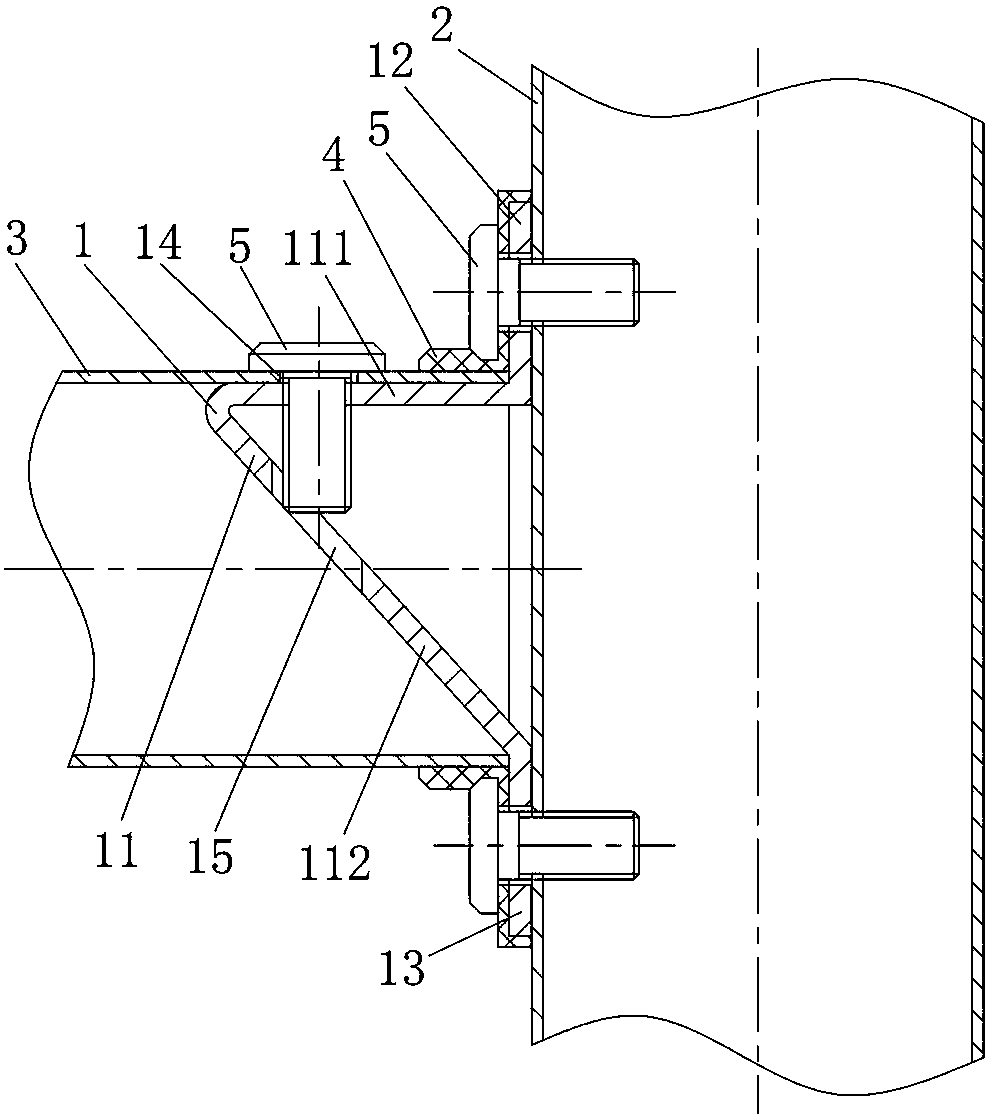

[0024] image 3 and Figure 4 It shows the second embodiment of the connecting assembly for columns and beams of the present invention, the connector body 1 in this embodiment is basically the same as the connector body 1 in Embodiment 1, the difference is that when the beam 3 is installed, The beam connecting part 11 is inserted in the beam 3, the upper column connecting part 12 and the lower column connecting part 13 protrude from the upper end and the lower end of the beam 3 respectively, and the supporting edge 111 holds the upper end of the inner wall of the beam 3 and passes the fastener 5 Linked to the upper wall of the beam 3, the fastener 5 passes through the upper arm of the beam 3 and the fastener installation hole 14 from the top of the beam 3 to connect with the supporting edge 111, and the fastener avoidance hole 15 on the inclined support edge 112 can prevent When the fastener 5 is too long, it interferes with the inclined support edge 112 .

[0025] Also be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com