Multifunctional composite window auxiliary frame

A composite window and multi-functional technology, applied in the field of window sub-frames, can solve the problems of poor airtightness and sound insulation performance, not suitable for use in coastal areas, easy deformation of steel window sub-frames, etc., and achieve good anti-aging performance, Excellent sound insulation performance, and the effect of reducing structural deformation of doors and windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

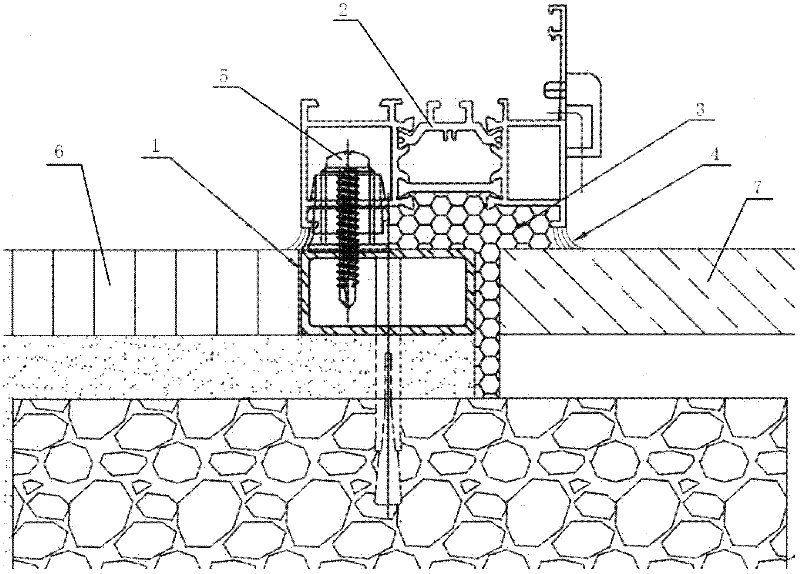

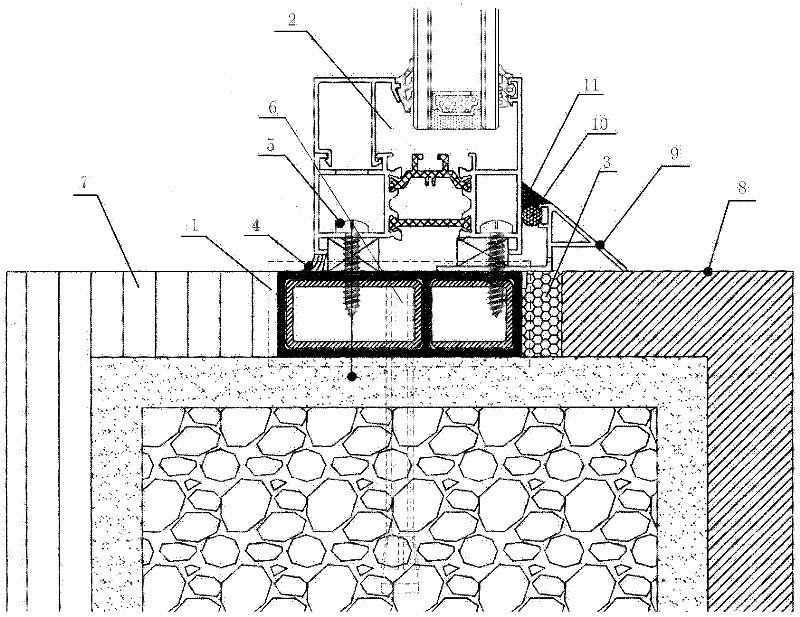

[0027] In order to describe the technical solutions and specific implementation methods of the present invention more clearly, the present invention will be further elaborated below in conjunction with the accompanying drawings.

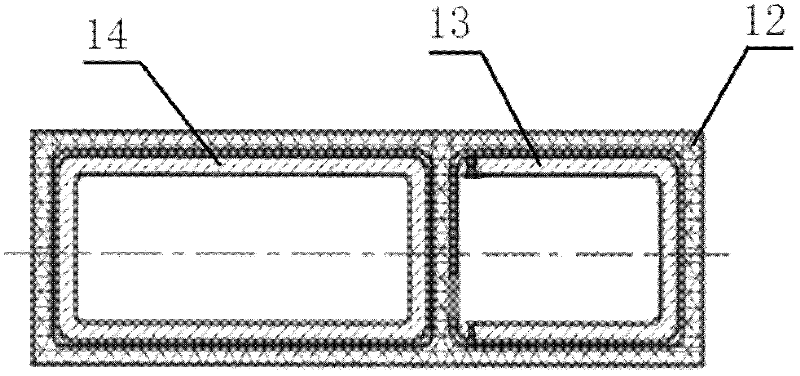

[0028] like figure 2 , 3 , 4, the multifunctional composite window sub-frame provided by the present invention includes a glass fiber reinforced plastic profile 12, a main lining steel 14 and a connecting lining steel 13, and the glass fiber reinforced plastic profile 12 has two insulation bridges 15 A cavity for accommodating the main lining steel 14 and connecting lining steel 13, according to the size of the window opening, take four sections of the profile 12 that are perpendicular to each other and fixed end to end on the wall of the window opening with expansion bolts to form a window subframe 1. The end-to-end joints of the four sections of profile 12 are sealed with sealant 11 , and the main lining steel 14 and connecting lining steel 13 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com