Gas extraction bored well and forming method

A gas drainage and drilling technology, applied in drilling equipment and methods, gas discharge, drilling equipment, etc., can solve problems such as blockage of screen pipe channels, deformation of screen pipes, and influence on normal gas drainage, so as to reduce damage and The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

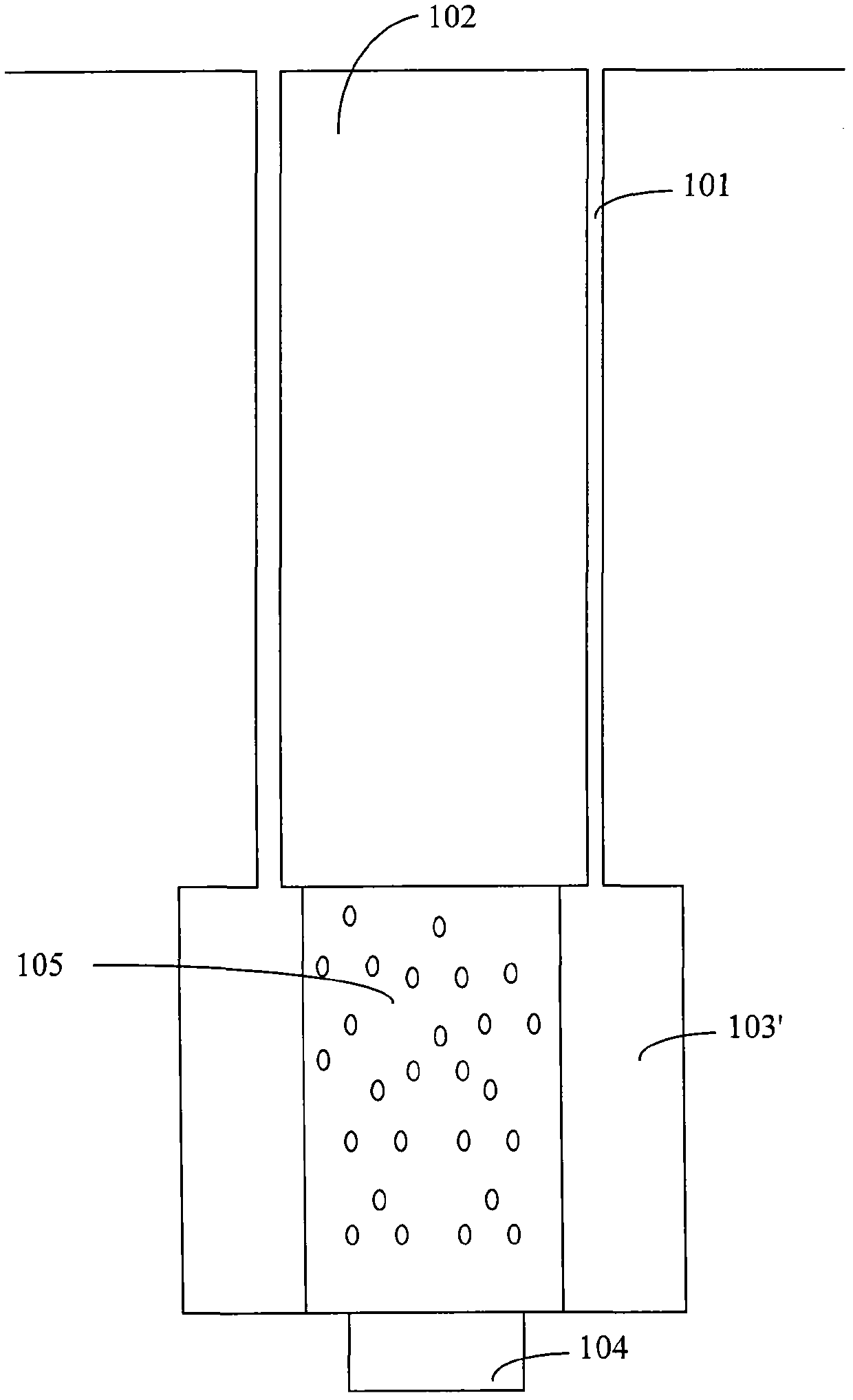

[0028] figure 1 The gas drainage drilling provided for Embodiment 1 of the present invention includes a casing section and a screen section. The casing section includes a casing section wellbore 101 and a casing 102. The screen section includes a screen section wellbore 103' and a screen pipe 105. Wherein, the screen pipe 105 is located in the well hole 103' of the screen pipe section, and the diameter of the well hole 103' of the screen pipe section is larger than the diameter of the well hole 101 of the casing section. distance. The so-called "safety distance" is the distance that can reduce the impact on the screen pipe when the rock stratum moves after the coal seam is mined.

[0029] Preferably, a bottom well hole 104 located directly below the well hole of the screen section is also included.

[0030] Preferably, the distance between the outer wall of the screen and the hole wall of the wellbore of the screen section is greater than or equal to 200 mm. For example, wh...

Embodiment 2

[0040] Figure 5 The flow chart for forming a gas drainage well provided in Embodiment 2 of the present invention may specifically be a method for forming a gas drainage well provided in any embodiment of the present invention.

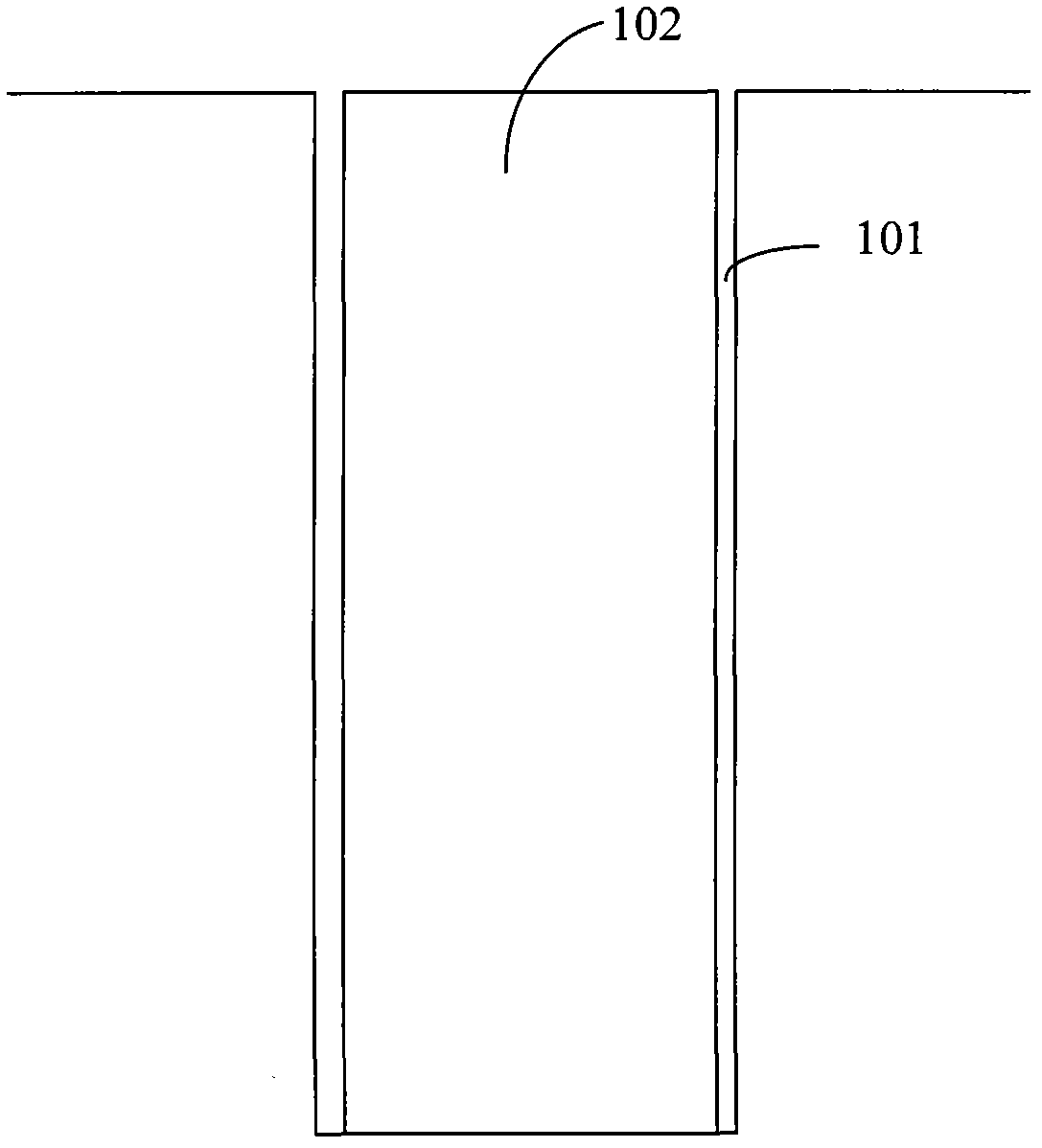

[0041] In step 501, a casing section wellbore is formed.

[0042] In step 502, a casing is placed and cemented in the casing section wellbore.

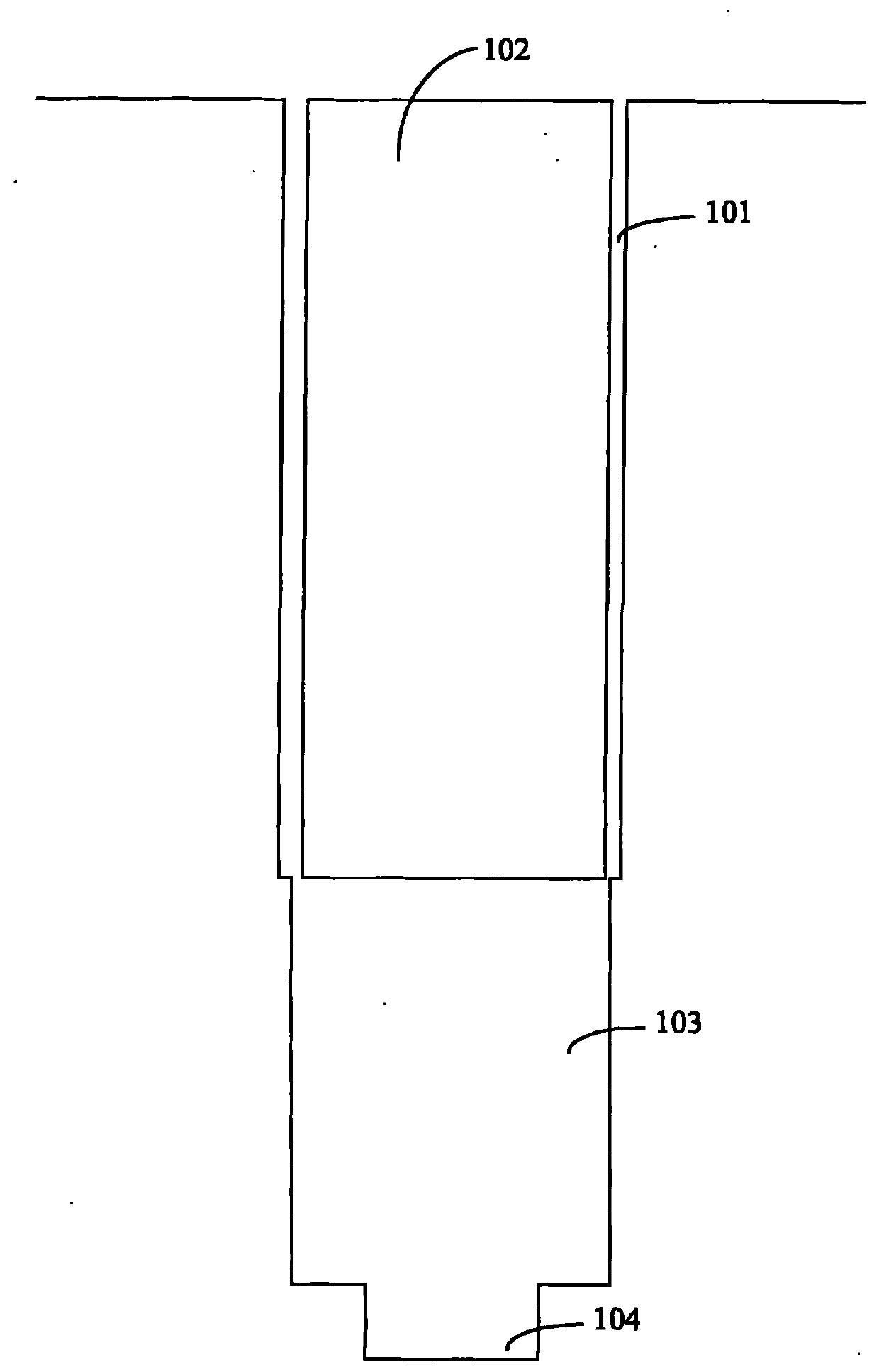

[0043] In step 503, drilling is performed right below the wellbore of the casing section, and reaming is performed to enlarge the diameter of the borehole below the casing section to be larger than the diameter of the wellbore of the casing section, so as to form the wellbore of the screen section.

[0044] In step 504, the screen is put into the wellbore of the screen section, and there is a safe distance between the outer wall of the screen and the hole wall of the wellbore of the screen section.

[0045] The value of the safety distance is preferably greater than or equal to 200mm. The diameter of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com