Pen-shaped cosmetic and manufacturing method thereof

A manufacturing method and technology of cosmetics, applied in the direction of cosmetic preparations, cosmetics, cosmetics, etc., can solve the problems of inconvenient feeling, and achieve the effect of excellent portability and excellent integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

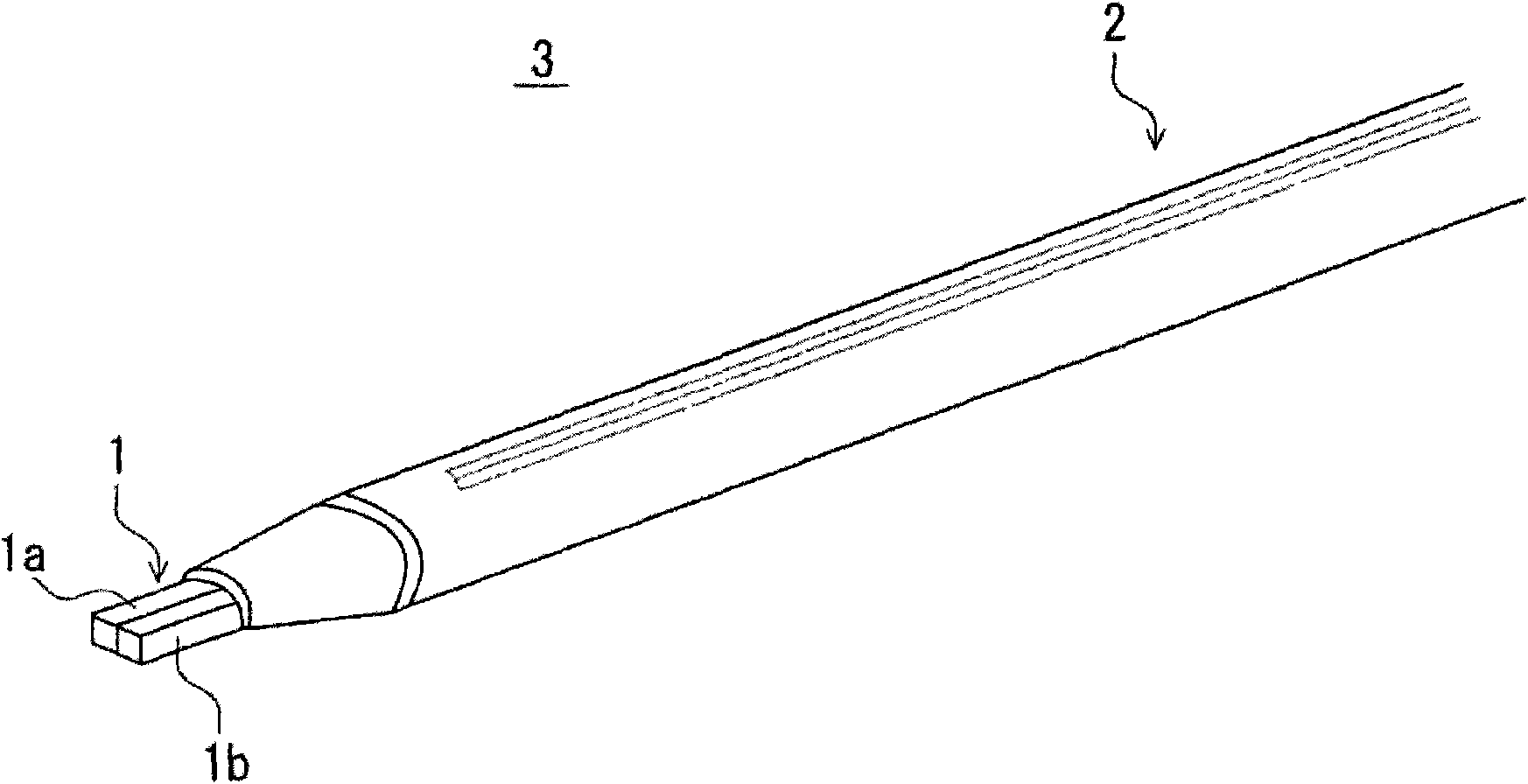

[0041] Embodiment 1 (preparation eyebrow pencil)

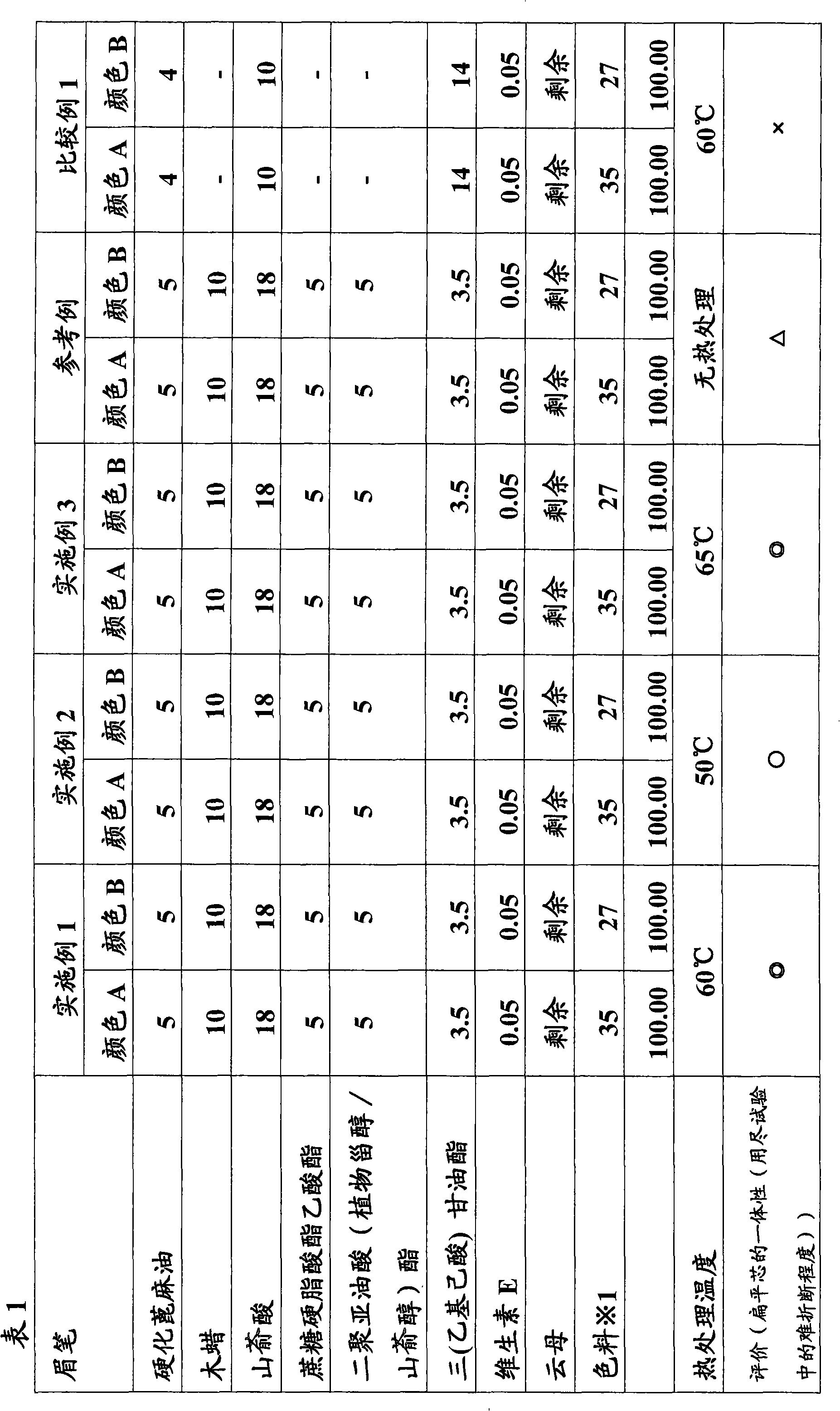

[0042] Color A and color B of the materials described in the following Table 1 were kneaded separately, and the kneaded product was loaded into a core molding machine equipped with a nozzle for core molding at the outlet, and the color A and color B were formed by extrusion and stretching. The kneaded bodies are combined at the front end of the nozzle to form a core body 1 having color stripes 1a, 1b divided into two types in the longitudinal direction. The cross-sectional dimensions of the color stripes 1a, 1b of the core body 1 are 1×1.5 (mm) respectively.

[0043]Next, it heat-processed at 65 degreeC for 3 hours, and made it cool slowly. Afterwards, wait for it to solidify to form the core body 1 . The size of the core body 1 is 1×3 (mm). The core 1 is used as a core that can be sent out successively, and is inserted into a mechanical pencil-shaped continuous feeder 2 to make it as follows: figure 1 Brow pencil 3 shown....

Embodiment 2~9

[0045] Embodiment 2~9, comparative example 1

[0046] In Example 2, except that the heat treatment temperature was 50° C. and in Example 3, the heat treatment temperature was 65° C., eyebrow pencils were prepared in the same manner as in Example 1 according to the recipes shown in Tables 1 to 3 below.

[0047] Reference example

[0048] Except not carrying out heat treatment, similarly to Example 1, eyebrow pencils were prepared according to the prescription shown in following Table 1.

Embodiment 1~3

[0049] About Examples 1-3, the reference example, and the integrity of the eyebrow pencil of Comparative Example 1 were evaluated according to the above-mentioned criteria, and the results are shown in Table 1.

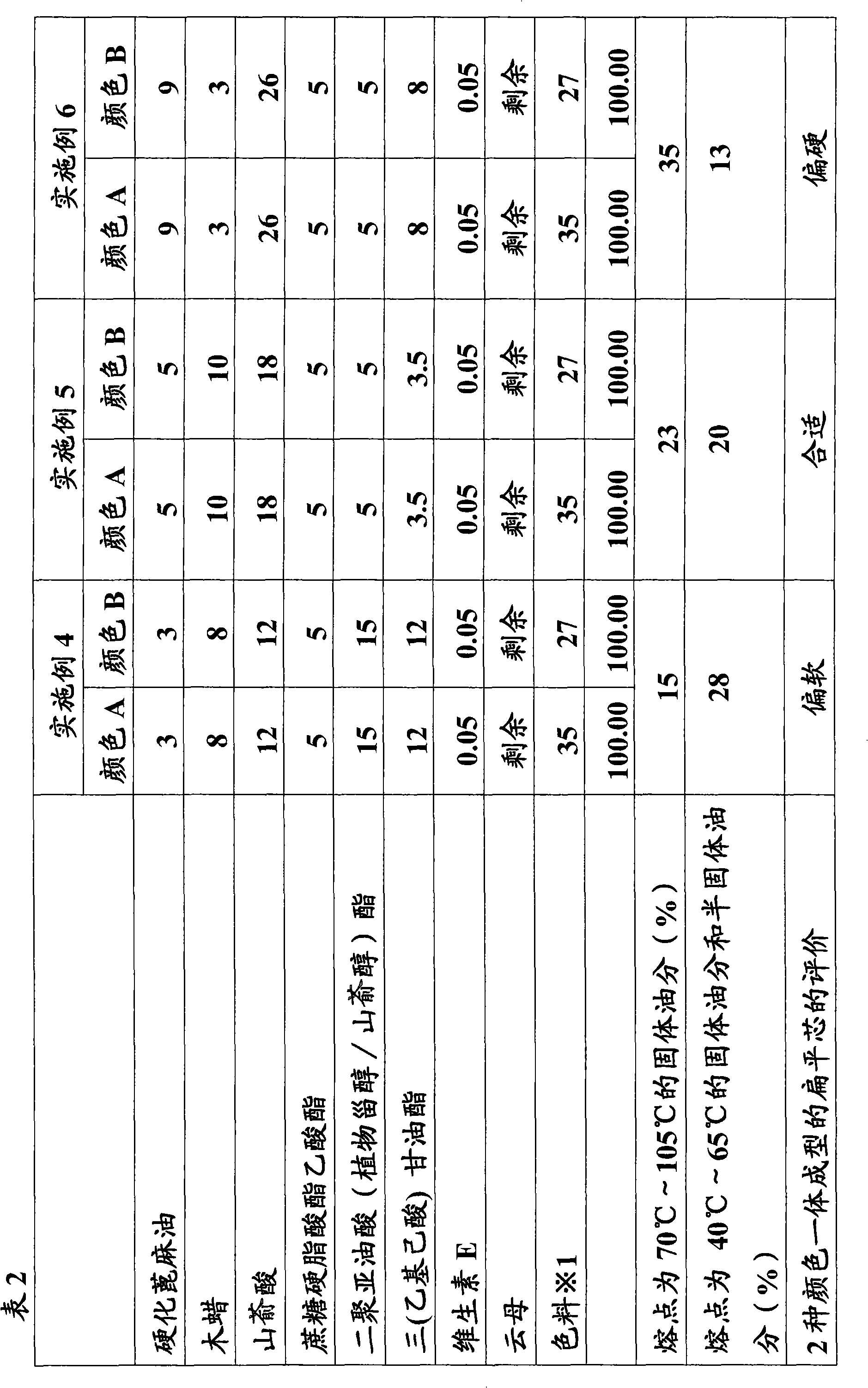

[0050] In addition, for Examples 4 to 9 in which the blending amount of solid oil with a melting point of 70°C to 105°C, semi-solid oil with a melting point of 40°C to 65°C, or solid oil was changed, the states of the obtained cores are shown in Table 2 and Table 2. 3.

[0051]

[0052]

[0053]

[0054] ※: Titanium oxide, iron oxide red, iron oxide yellow, and iron oxide black are used in both color A and color B, and the mixing ratio is different for each color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com