Combined heat-insulation casing for pipeline elbows

A technology of pipe elbow and thermal insulation shell, which is applied in pipeline protection, thermal insulation, and pipeline protection through thermal insulation, etc., can solve the problems of non-reusable, cumbersome and time-consuming installation, and long processing period, so as to improve work efficiency and reduce construction and maintenance. Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments.

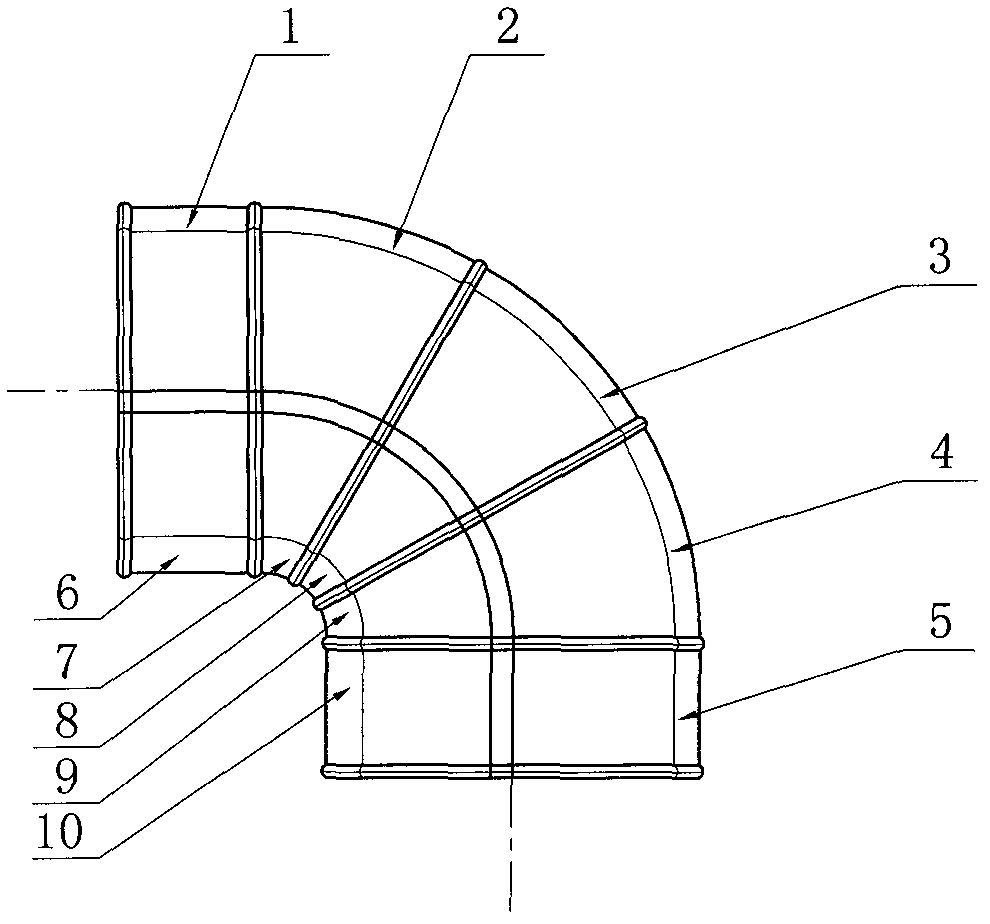

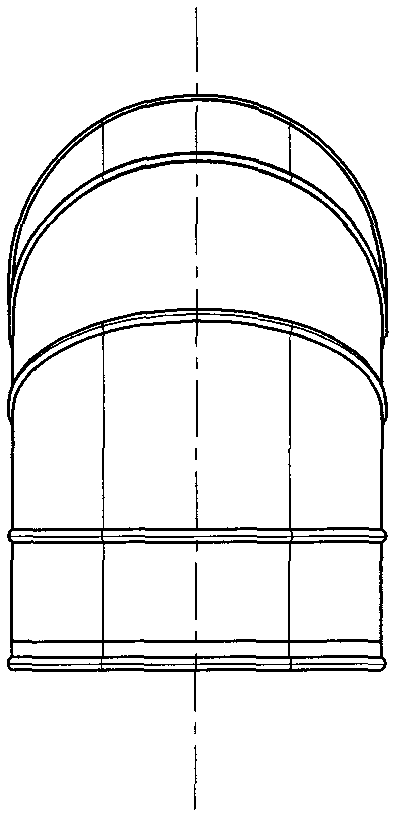

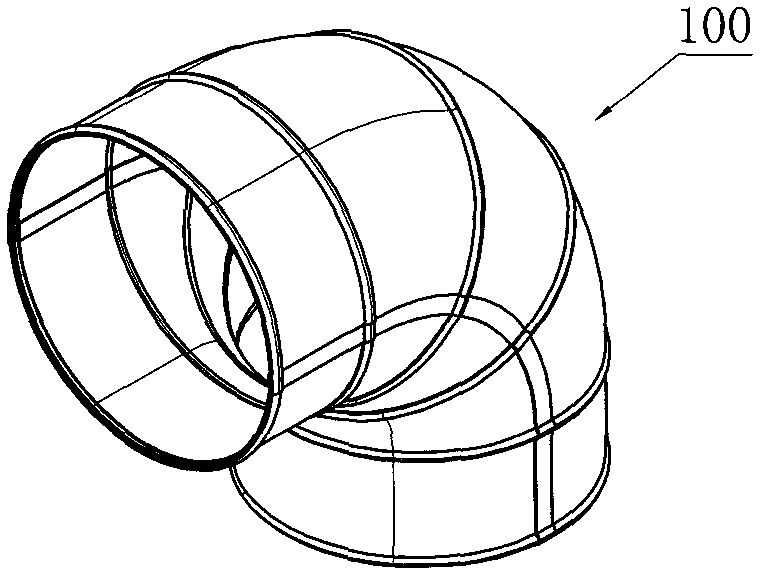

[0013] Reference figure 1 , figure 2 , image 3 with Figure 4 , A combined pipeline elbow heat preservation shell 100 for engineering pipelines is composed of an outer elbow shell 30 and an inner elbow shell 20, wherein the outer elbow shell 30 is composed of an outer straight-up circular arc plate (1, 5) and an outer The inner elbow shell 20 is composed of the inner straight-up circular arc plate (6, 10) and the inner straight-up combined board (7, 8, 9), and the outer straight-up circular arc There are two pieces of plates (1, 5), and there can be one or more pieces of the outer halving combination plate (2, 3, 4), and the inner straight-up arc plate (6, 10) has two pieces. The inner halving combination plate (7 , 8, 9) There can be one or more pieces, and the combined pipe elbow thermal insulation shell 100 is formed by pressing a thin metal plate. In each piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com