Control method and control system capable of preventing liquid heating equipment from parching

A technology of heating equipment and control system, which is applied in the direction of lighting and heating equipment, fluid heaters, etc., can solve the problems of electric heating life impact, safety issues not guaranteed, safety accidents, etc., to avoid long-term power-on work and The effect of dry burning, improving service life and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

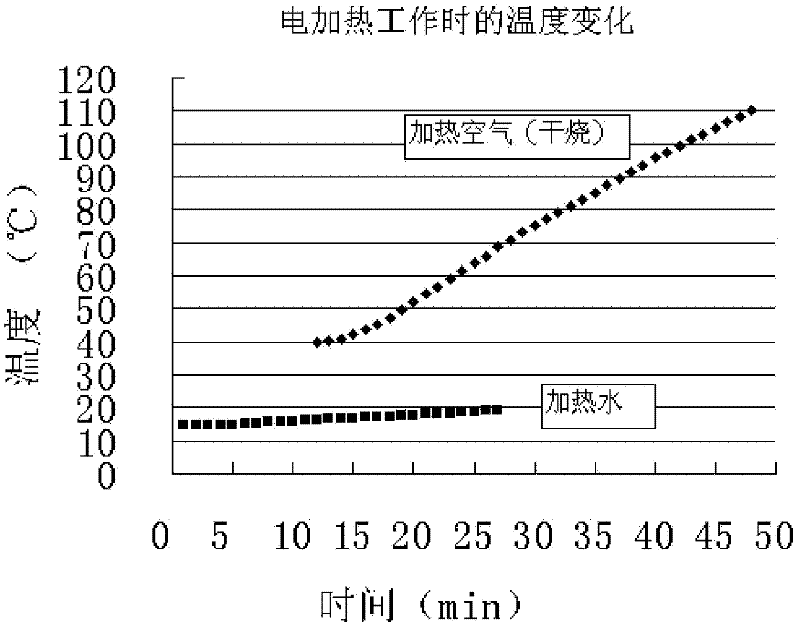

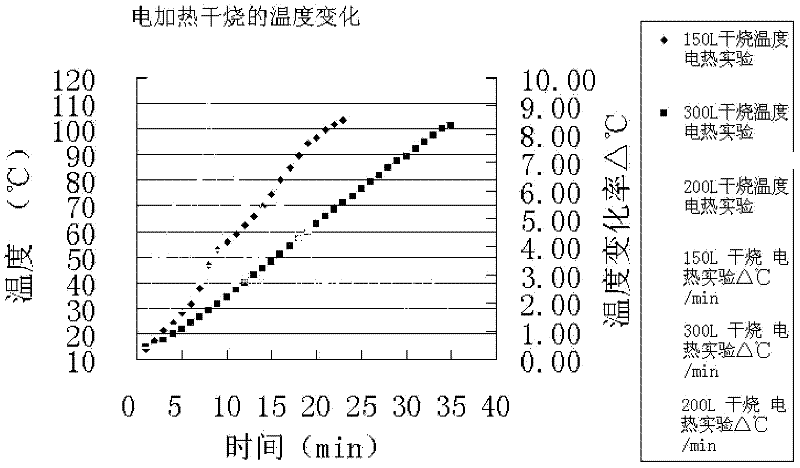

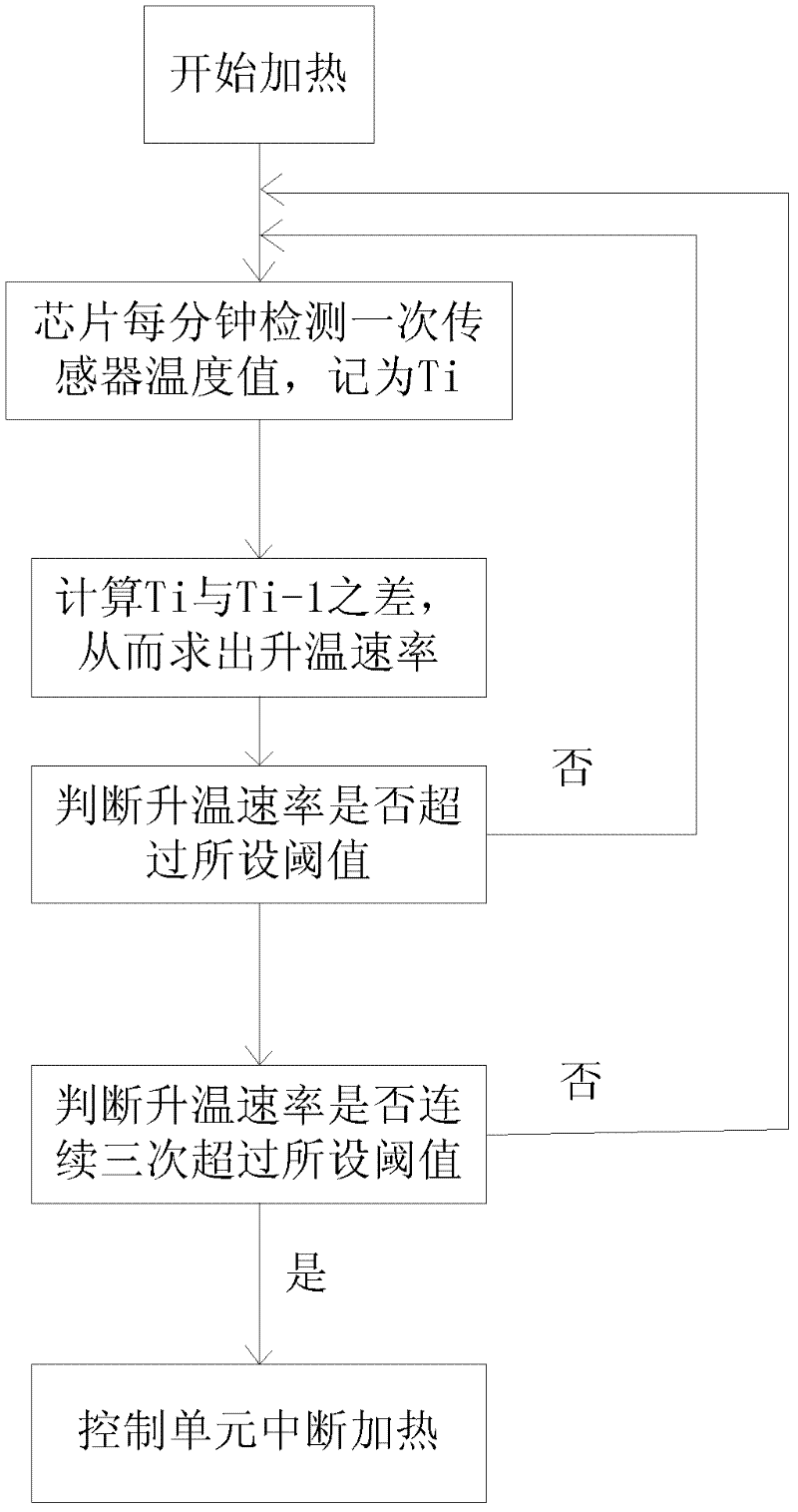

[0058] The first preferred embodiment of the present invention provides such a control method for preventing dry burning of liquid heating equipment. The method uses a temperature measuring unit to collect temperature data in the heating equipment, and detects the temperature every 1 minute, denoted as Ti. The calculation unit subtracts the measured temperature Ti from the last measured temperature Ti-1 to obtain the temperature increase value ΔT within this minute. The temperature increase rate ΔT / t can be obtained by dividing the temperature increase value ΔT by the time interval of 1 minute.

[0059] The first judging unit compares the temperature increasing rate ΔT / t with the set temperature increasing rate threshold, if the temperature increasing rate threshold is not exceeded, the control unit judges that no dry burning occurs, continues normal heating and repeats the above detection and judging steps ; If the temperature increase rate ΔT / t exceeds the set temperature in...

no. 2 example

[0064] In the second embodiment, the control method for preventing dry burning of the liquid heating equipment uses the temperature measuring unit to collect temperature data in the heating equipment, and detects the temperature every 2 minutes, denoted as Ti. The calculation unit subtracts the measured temperature Ti from the last measured temperature Ti-1 to obtain the temperature increase value ΔT within these 2 minutes. The temperature increase rate ΔT / t can be obtained by dividing the temperature increase value ΔT by the time interval of 2 minutes.

[0065] The first judging unit compares the temperature increasing rate ΔT / t with the set temperature increasing rate threshold, if the temperature increasing rate threshold is not exceeded, the control unit judges that no dry burning occurs, continues normal heating and repeats the above detection and judging steps ; If the temperature increase rate ΔT / t exceeds the set temperature increase rate threshold, record it as an abn...

no. 3 example

[0072] In this embodiment, a heating device capable of preventing dry burning of liquid heating equipment is provided, the heating device includes a container for containing liquid, an electric heating tube 2, a temperature measuring unit, and a main chip, wherein the main chip includes a computing unit, a first A judging unit, a recording unit, a second judging unit, and a control unit, wherein the electric heating tube heats the liquid in the container, and the temperature measuring unit detects the temperature and transmits signals. The calculation unit on the main chip calculates the temperature rise rate inside the heating device; the first judging unit judges whether the temperature rise rate exceeds the set temperature rise rate threshold of 1°C / s; the recording unit records that the temperature rise rate continuously exceeds the temperature rise rate threshold The second judging unit further judges whether the number of consecutively exceeding the heating rate reaches 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com