Heat exchanger

A technology of heat exchangers and plate heat exchangers, which is applied in the direction of heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as cracking of raised side walls and affecting the life of heat exchangers, and achieve increased performance, save welding materials, strong strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Figure 4 A plate heat exchanger (9) such as the exemplary embodiment shown in is a well known device for heat transfer between two different fluids. Plate heat exchangers (9) are used in many different applications, for example in the automotive industry, for cooling and heating buildings etc.

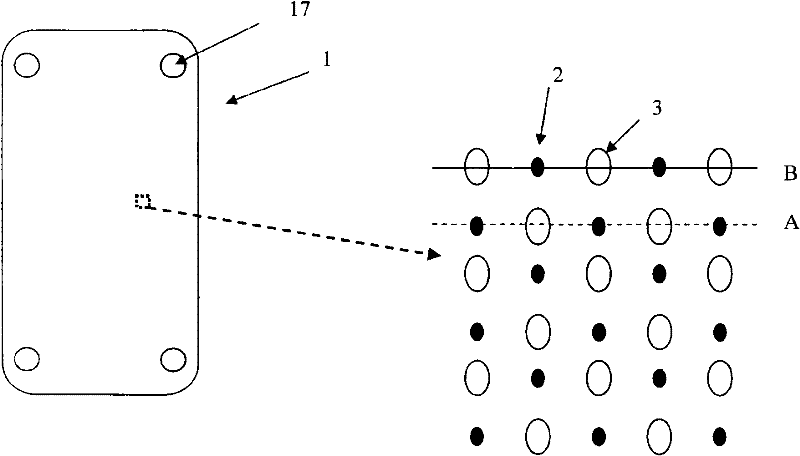

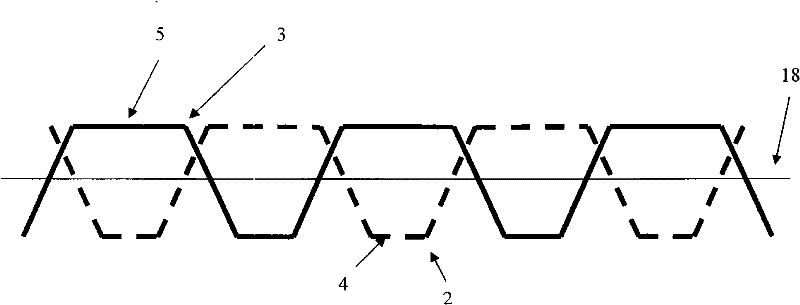

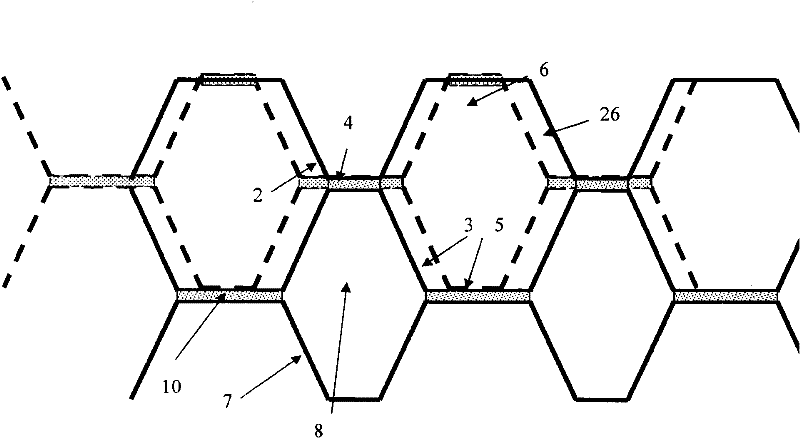

[0035] A plate heat exchanger (9) comprises a plurality of heat exchanger plates (1, 13) stacked on top of each other. Each heat exchanger plate (1, 13) is designed with an indentation pattern (2, 3, 14, 15), typically designed as protrusions and hollows and / or as ridges and recesses (the ridges and recesses being specifically combined with herringbone design). On the very top and the very bottom of the plate heat exchanger (9) flat metal plates (16) are provided for keeping the fluid inside the plate heat exchanger (9). Furthermore, connections (11, 12) for the inlet (11) and outlet (12) of the two fluids are provided.

[0036] A stack of heat exchanger plates (1, 13) is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com