Test method for natural frequency of blade of integral blade disc

A technology of integral blisk and natural frequency, applied to vibration measurement in solids, measurement of resonance frequency, measurement of vibration and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

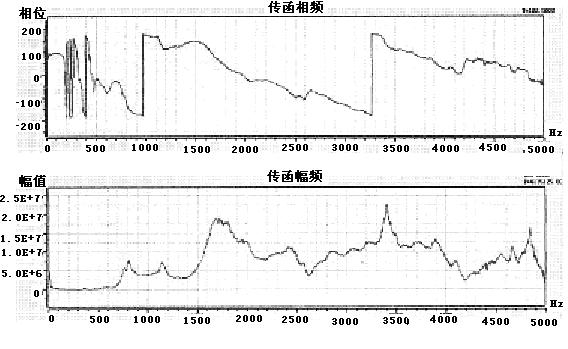

[0032] Three kinds of free damping materials: rubber tube, foam block, and rubber foam are tested for damping characteristics, and the transfer function analysis of the damped blade is carried out, see Figure 1~Figure 3 , From the above three figures, it can be seen that the transmission curve of the blade constrained by rubber foam is flatter below 4KHz, which means that the resonance peak of the blade using rubber foam is more effectively suppressed.

Embodiment 2

[0034] In order to study the dynamic characteristics of a single blade on the blisk in depth, the method of applying engineering damping (rubber foam) to all non-tested blades on the blisk, such as Figure 4 shown, while Figure 5 with Image 6 It is the time-domain diagram of the free damping vibration after being stimulated by the propelling excitation under the two conditions before and after the blade is constrained. It can be seen from the figure that this damping method effectively solves the coupling vibration between the blades, thereby improving the blade mode. The accuracy of the state test.

[0035] Example 2

[0036] To detect the natural frequency of a blisk blade, first, use a clamp to fix the blisk on the vibration table; then, use rubber foam to damp the non-tested blades in the blisk blade (see Figure 4 ), and then divide the measured leaf into 7 parts on average to get 14 nodes (see Figure 7 ); each node is knocked with an aluminum hammer, and the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com