Dynamic compaction test bed

A technology of test bench and jib, which is applied in the field of testing and testing of dynamic compaction machines, can solve problems such as hidden dangers of machinery and personnel safety, test new technology, instability, etc., to protect the safety of machinery and personnel, ensure safety, and ensure the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

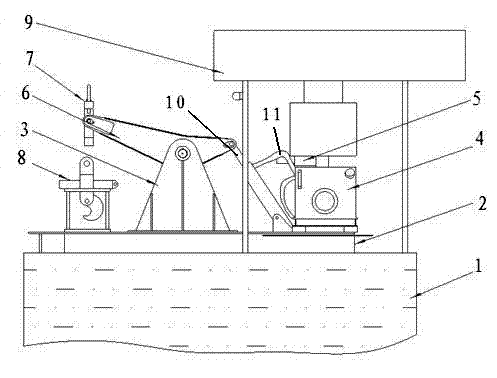

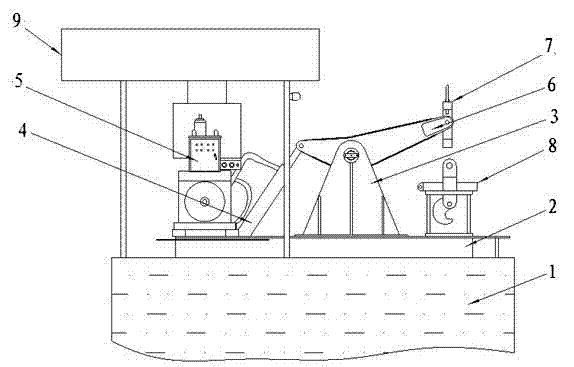

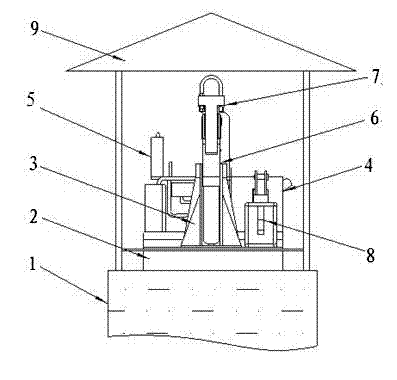

[0017] Embodiment 1: as Figures 1 to 4 As shown, the dynamic tamping test bench of this embodiment is composed of a base 2, a support 3, a hydraulic device 4, an electrical device 5, a jib 6, a spreader assembly 7, a machine cover 9, a hydraulic cylinder 10, and a hydraulic pipe 11.

[0018] The base 2 is placed stably on the flat and strong test bench foundation 1, the hood 9 is set on the base 2, the hydraulic device 4 and the electrical device 5 are installed under the hood 9, and the hydraulic device 4 is provided with a hydraulic cylinder 10 and The hydraulic pipe 11 , the hydraulic device 4 and the electrical device 5 cooperate with each other to provide power for the hydraulic pipe 11 .

[0019] The base 2 is also provided with a triangular support 3, the top of the support 3 is provided with a rotatable arm frame 6, the moment of one side of the arm frame 6 is short, the moment of one side is long, and the side of the short moment is connected with the hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com