Portable device for observing metal surface and metallographic phase

A metal surface and observation device technology, which is applied to measurement devices, preparation of test samples, material analysis by optical means, etc., can solve the problems of inconvenient observation operation and inconvenient direct observation of the coating surface of metal workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

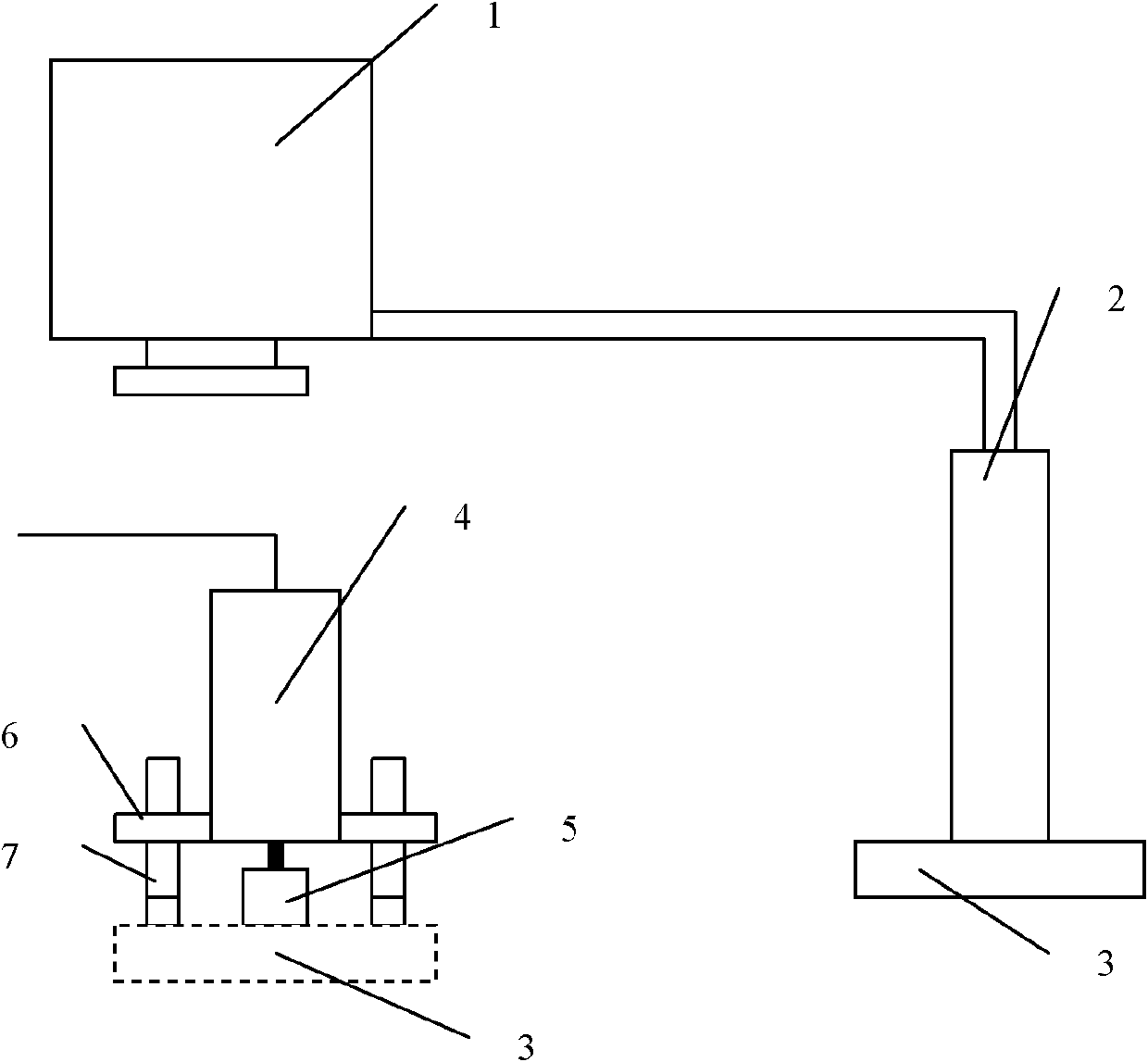

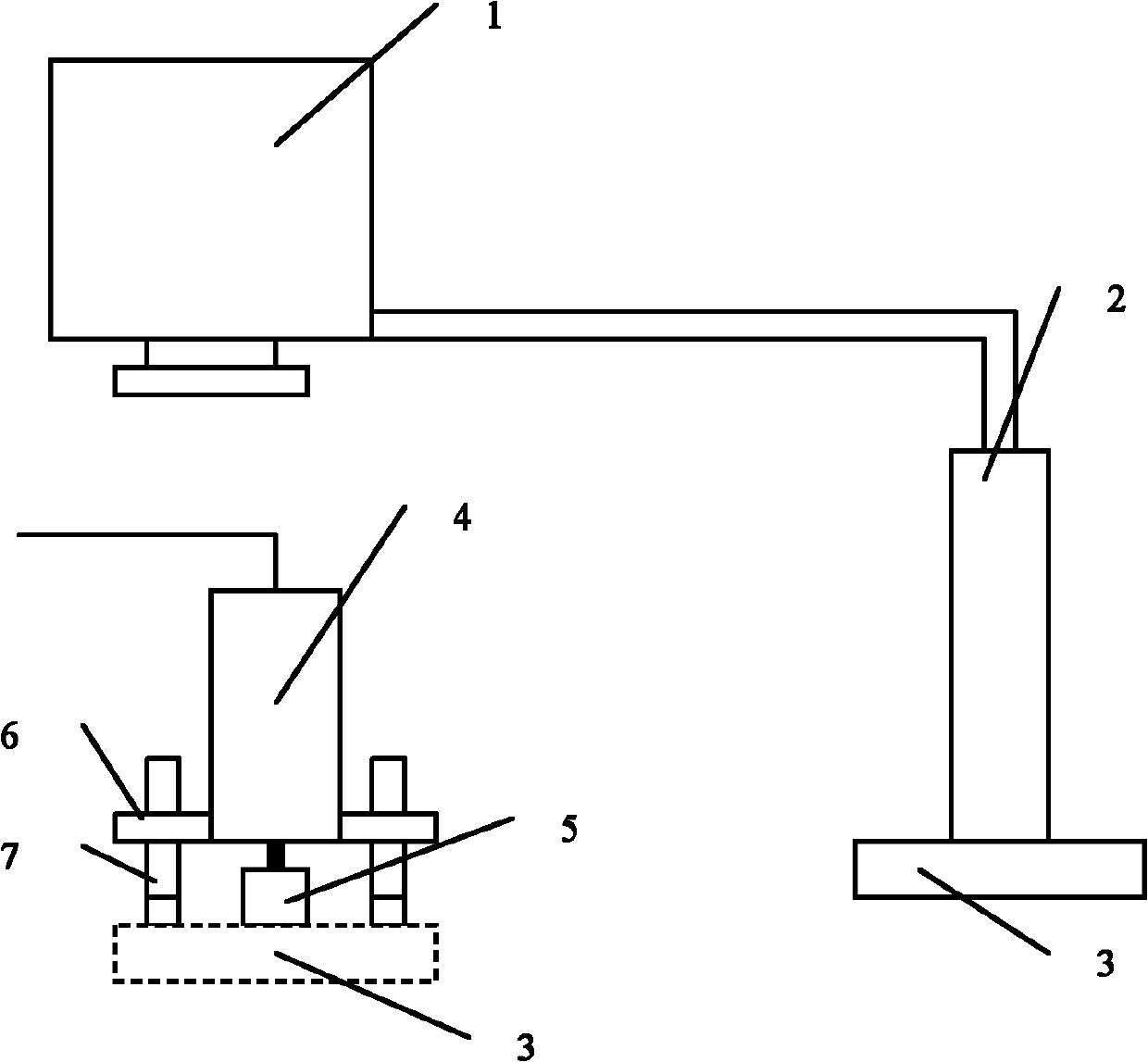

[0016] Such as figure 1 As shown, the portable metal surface and metallographic observation device of the present invention mainly includes: display 1, digital microscope (400 times) 2, metal surface 3, polisher (can do short-distance X, Y translation) 4, polishing grinding head 5. Adjustable brackets (four) 6, etc., the specific structure is as follows:

[0017] The metal surface 3 before polishing corresponds to the polisher 4, and the polishing grinding head 5 is installed on one end of the polisher 4, and the adjustable support 6 is arranged symmetrically on the polisher 4, and the adjustable support 6 is connected to the metal surface 3 by the stud 7 threaded therewith. touch, the friction force between the polishing grinding head 5 and the metal surface 3 can be adjusted conveniently.

[0018] The polished metal surface 3 corresponds to the camera end of the digital microscope 2, and the output end of the digital microscope 2 is connected to the display 1, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com