High-precision multi-tooth dividing plate magnification changing mechanism in optical system

An optical system and indexing disc technology, applied in optics, optical components, installation, etc., can solve problems such as high manufacturing and operating costs, complex working methods of optical zoom systems, poor repeat positioning accuracy, etc., and achieve optical axis reset high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

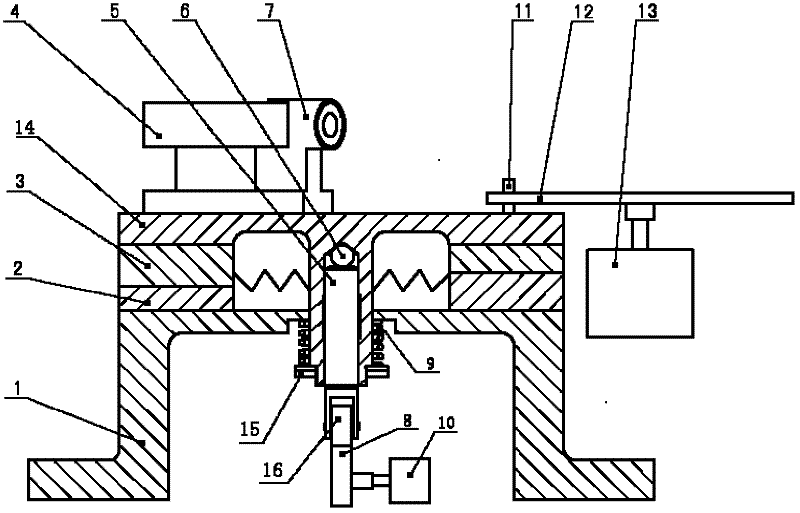

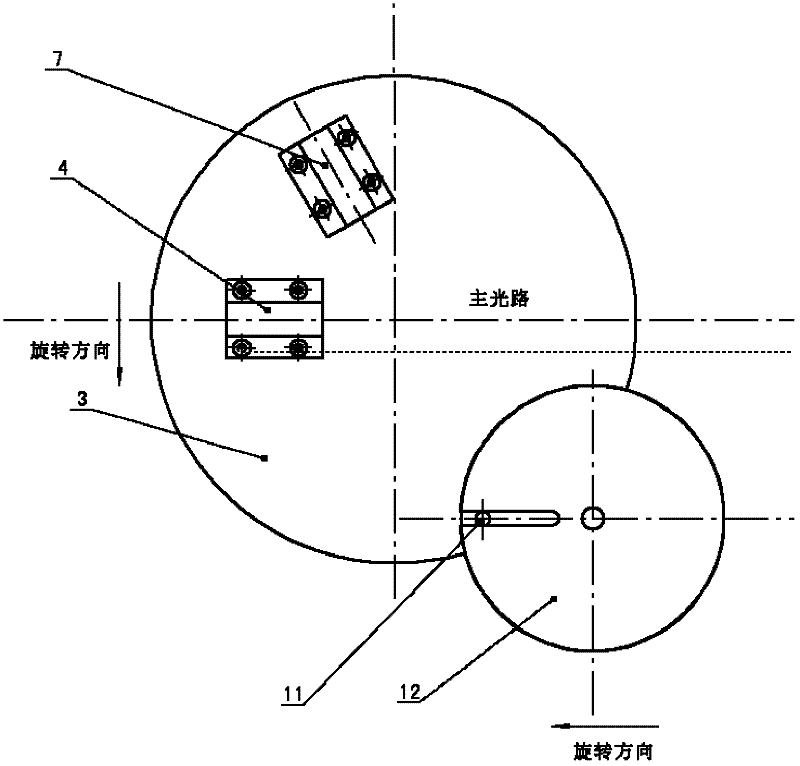

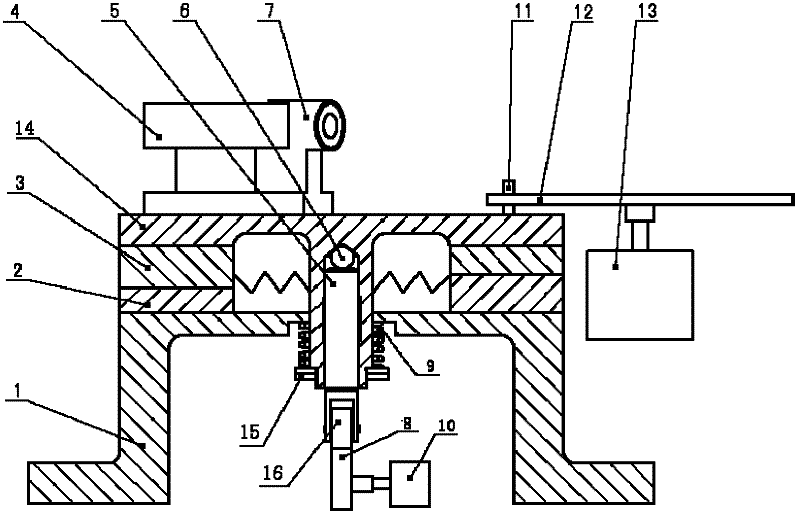

[0009] Such as figure 1 with figure 2 As shown, a high-precision multi-tooth indexing disk-type zoom mechanism in an optical system includes a base 1, a multi-tooth indexing disk, a zoom lens group I 4, an ejector 5, a steel ball 6, and a zoom Mirror group II7, lifting cam 8, return spring 9, lifting motor 10, guide post 11, dial 12, rotating motor 13, rotating platform 14, lock nut 15 and roller 16; a through hole is provided in the center of the base 1, A cylindrical body is provided at the center of the rotating platform 14 to cooperate with the through hole, the center of the cylindrical body is provided with a blind hole from the lower end upward, the ejector rod 5 is installed in the blind hole, and the steel ball 6 is installed on the top. The upper end of the rod 5, the roller 16 is arranged at the lower end of the top rod 5, the lifting cam 8 is arranged at the lower end of the roller 16, the lifting cam 8 is installed on the lifting motor 10; the bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com