Design method of automobile control arm

A technology of automotive control arm and design method, which is applied in computing, special data processing applications, instruments, etc., can solve problems such as high development cost, unreasonable design, and control arm that does not meet the design requirements, so as to shorten the development cycle and reduce R&D The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

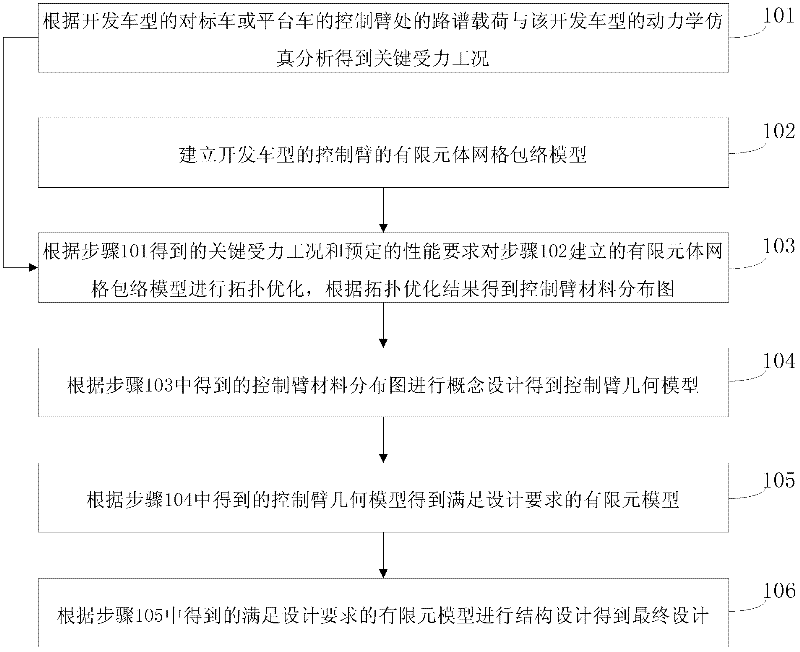

[0047] This embodiment provides a method for designing an automobile control arm, see figure 1 , the method flow is as follows:

[0048] 101: According to the road spectrum load at the control arm of the benchmark vehicle or platform vehicle of the developed model and the dynamics simulation analysis of the developed model, the key stress working conditions are obtained;

[0049] 102: Establish the finite element body mesh envelope model of the control arm of the developed vehicle model;

[0050] 103: Perform topology optimization on the finite element volume mesh envelope model established in step 102 according to the key stress conditions and predetermined performance requirements obtained in step 101, and obtain a material distribution diagram of the control arm according to the topology optimization result;

[0051] 104: Perform conceptual design according to the material distribution diagram of the control arm obtained in step 103 to obtain a geometric model of the contr...

Embodiment 2

[0056] Embodiment two

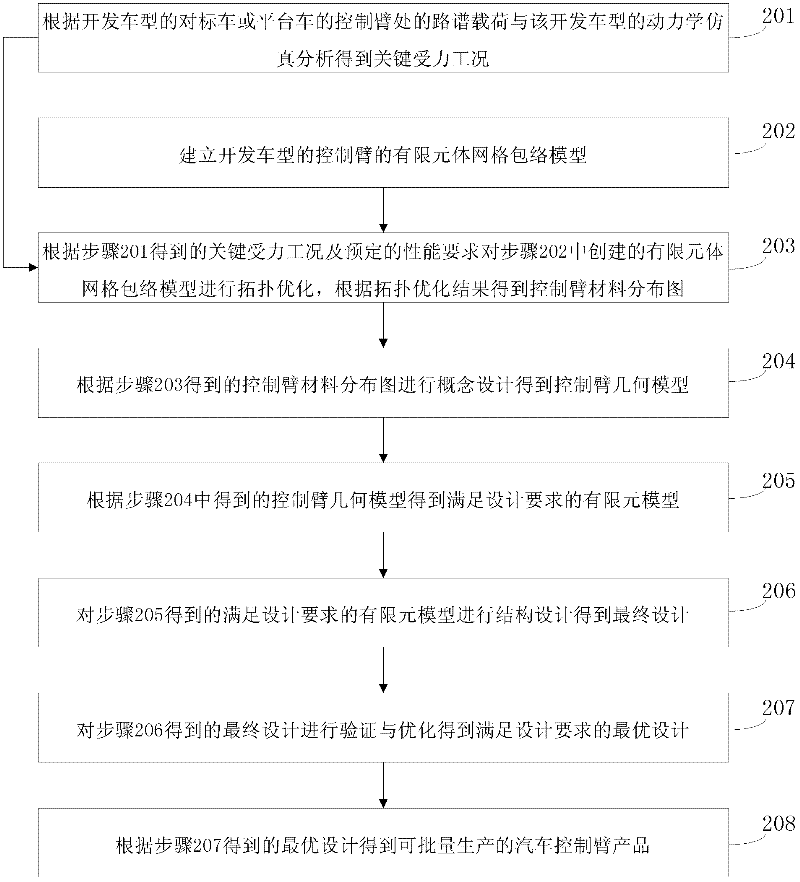

[0057] This embodiment provides a method for designing an automobile control arm, see figure 2 , the method flow provided by this embodiment is specifically as follows:

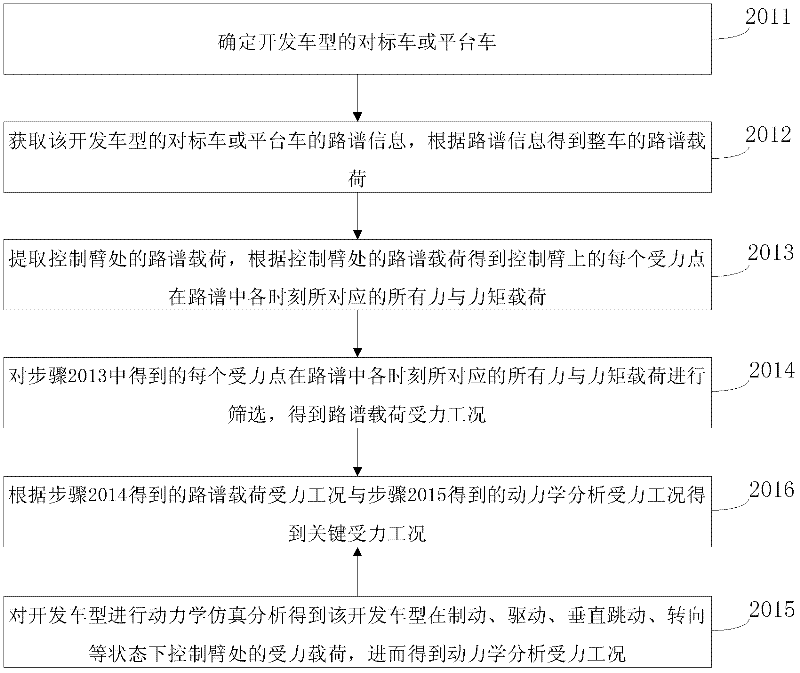

[0058] 201: According to the road spectrum load at the control arm of the benchmark car or platform car of the developed model and the dynamics simulation analysis of the developed model, the key stress working conditions are obtained; among them, see image 3 , the specific process of step 201 is as follows:

[0059] 2011: Determine the benchmark car or platform car for the development model, and define the suspension system performance parameters of the development model, such as mode, stiffness, handling performance, etc., and decompose the performance into chassis components, such as the control arm place;

[0060] 2012: Obtain the road spectrum information of the benchmarking vehicle or platform vehicle of the developed model, and obtain the road spectrum load of the whole veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com