Automatic disk grabbing device for compact-disk server

A disc grabber and disc library technology, applied in the direction of instruments, recording information storage, etc., can solve the problems of high energy consumption, easily damaged disc storage data, low work efficiency, etc., to achieve convenient operation, improve storage density and space use Effect, effect of protecting reliability and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

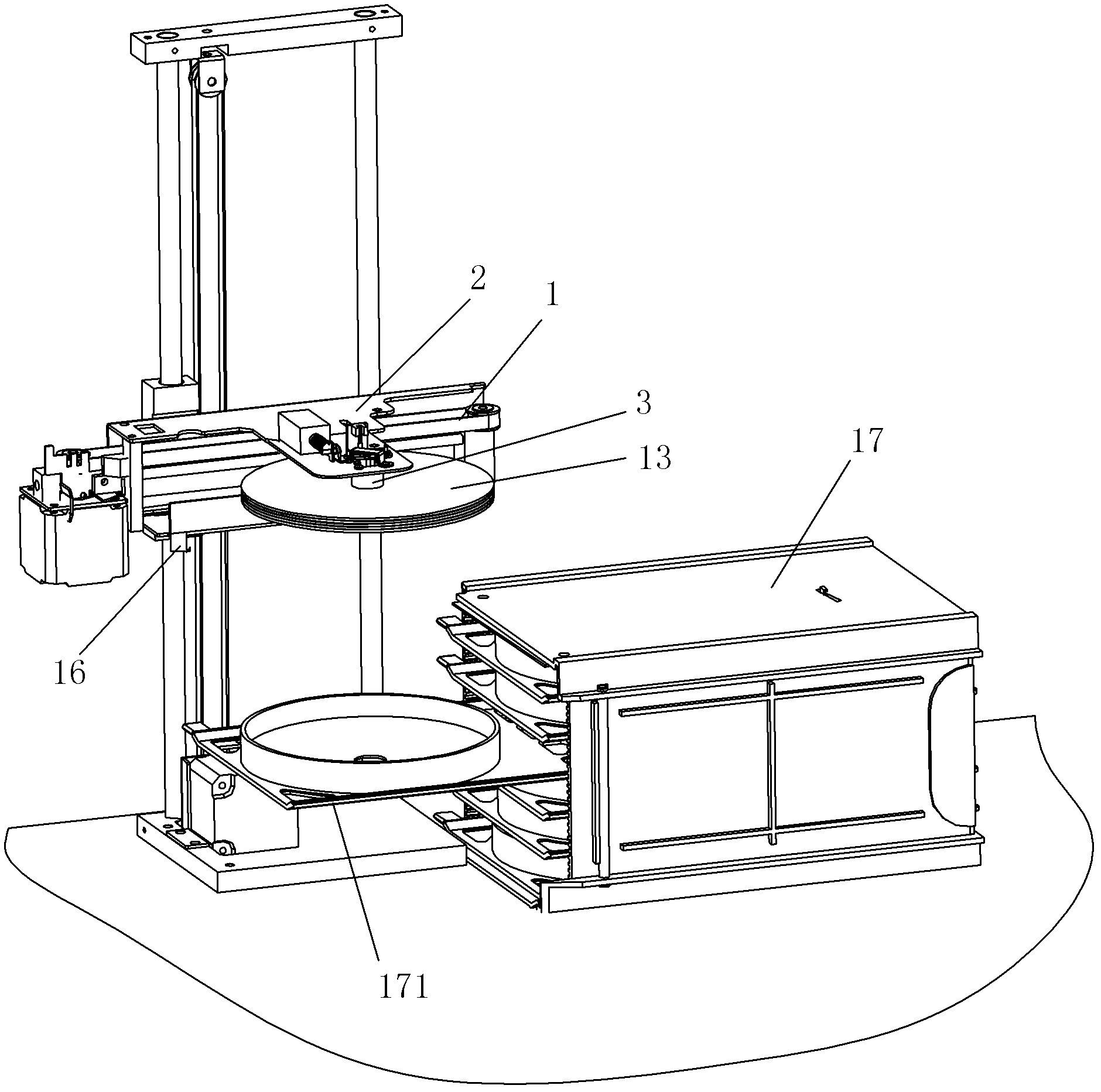

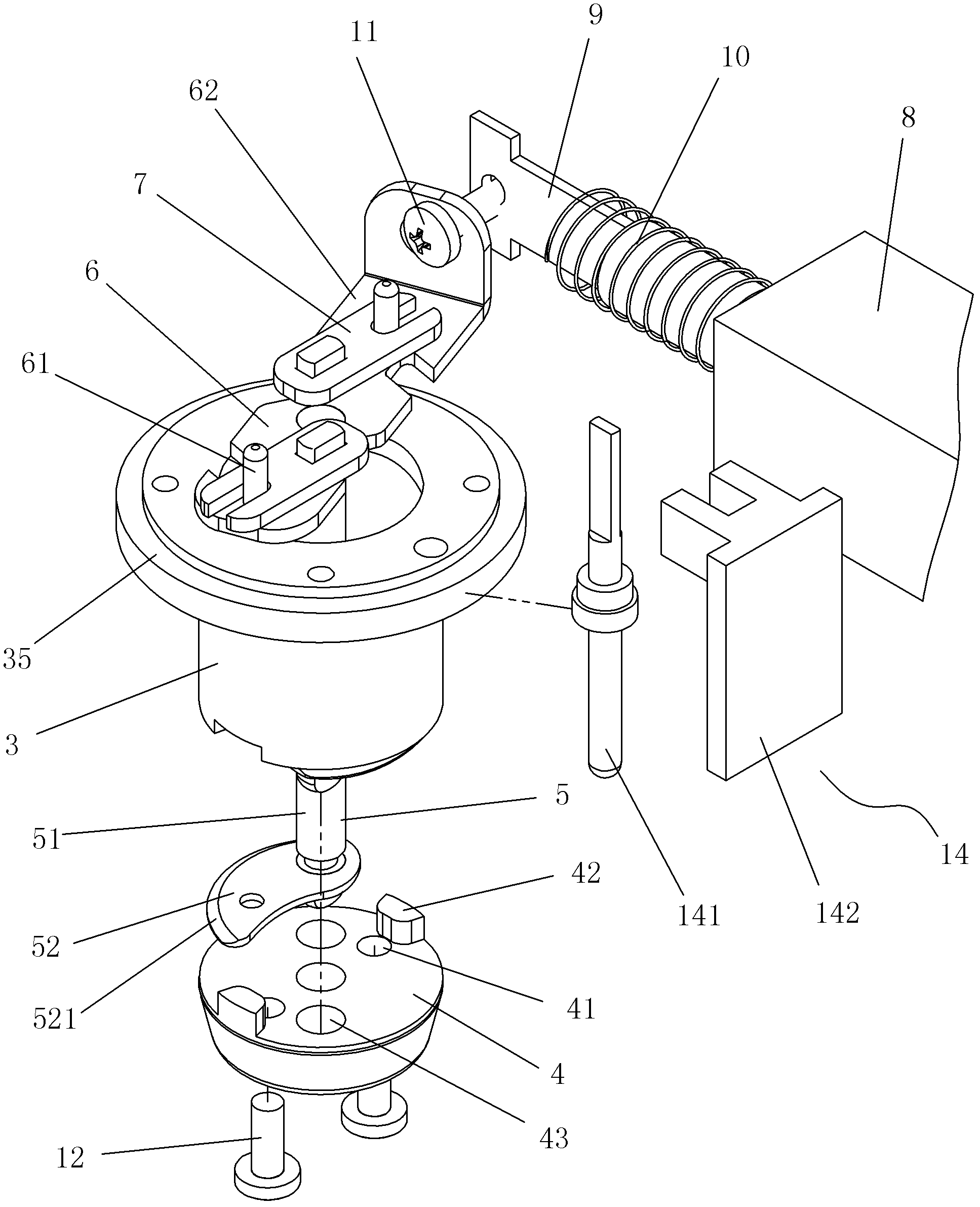

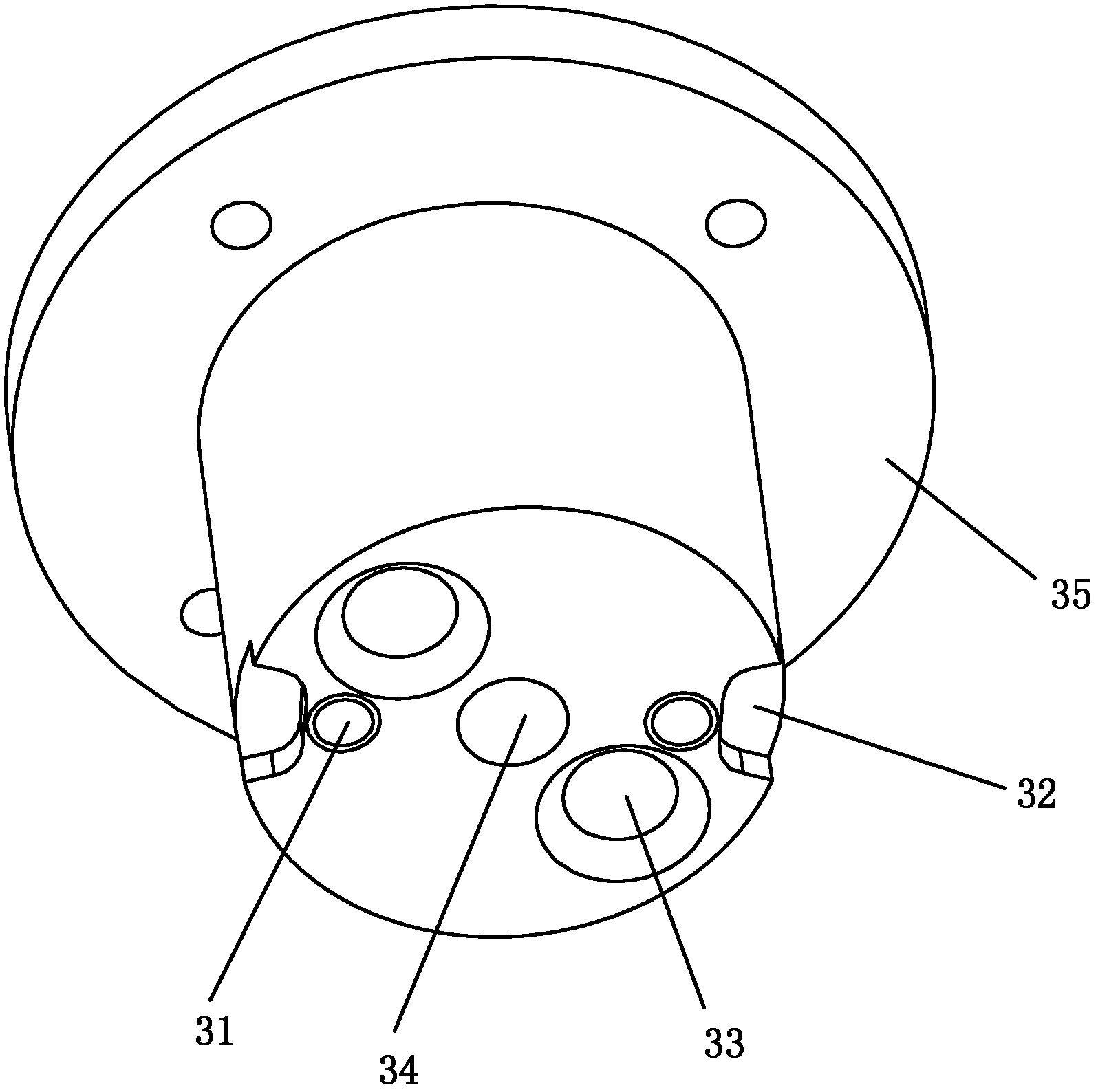

[0029] Example: as Figure 1 to Figure 12 As shown in the figure, an automatic disc grabber for an optical disc library includes a support plate 2 that moves vertically and horizontally with the manipulator displacement device 1, and the support plate 2 is provided with a main rod 3 extending downward from the support plate 2. , the lower end of the main rod 3 is provided with a tapered rod 4, between the main rod 3 and the tapered rod 4 are provided two first rotating parts 5, the first rotating part 5 has a vertical shaft 51 and is arranged on the vertical shaft 51 and located at The pull-up plate 52 in the gap between the main rod 3 and the taper rod 4, the upper end of the main rod 3 is provided with a second rotating member 6 that can rotate relative to the main rod 3, and the second rotating member 6 is provided with two convex columns 61. The vertical shaft 51 passes through the vertical shaft hole 33 of the main rod 3 and is fixed with a connecting piece 7 at the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com