Protective agent and surface treatment method for reducing contact resistance of rivet electrical contacts

A contact resistance and surface treatment technology, applied in chemical instruments and methods, circuits, relays, etc., can solve problems such as large resistance and affect the reliable operation of relays, and achieve the effect of reducing surface contact resistance and protecting long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

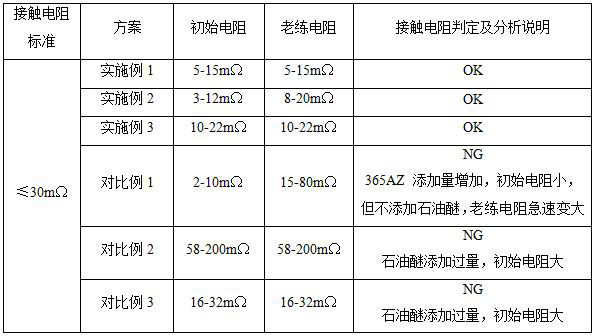

Embodiment 1

[0012] The protective agent of this embodiment adopts the raw material (V / V) of the following proportions: petroleum ether 1.5%; 365AZ 98.5%. During preparation, the two reagents are mixed in a container and stirred evenly. When in use, immerse 1kg of rivet electrical contacts in the mixture consisting of petroleum ether and 365AZ, take out the rivet electrical contacts after 5 minutes and dry them with hot air at 140°C.

Embodiment 2

[0014] The protective agent of this embodiment adopts the raw material (V / V) of the following proportions: petroleum ether 0.5%; 365AZ 99.5%. During preparation, the two reagents are mixed in a container and stirred evenly. When in use, immerse 1kg of rivet electrical contacts in the mixture consisting of petroleum ether and 365AZ, take out the rivet electrical contacts after 5 minutes and dry them with hot air at 140°C.

Embodiment 3

[0016] The protective agent of this embodiment adopts the following raw materials (V / V): petroleum ether 2.5%; 365AZ 97.5%. During preparation, the two reagents are mixed in a container and stirred evenly. When in use, immerse 1kg of rivet electrical contacts in the mixture consisting of petroleum ether and 365AZ, take out the rivet electrical contacts after 5 minutes and dry them with hot air at 140°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com