Electro-slag re-melting water-cooling cable

A water-cooled cable, electroslag remelting technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of water-cooled cable damage and water leakage, and achieve the effect of avoiding water leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

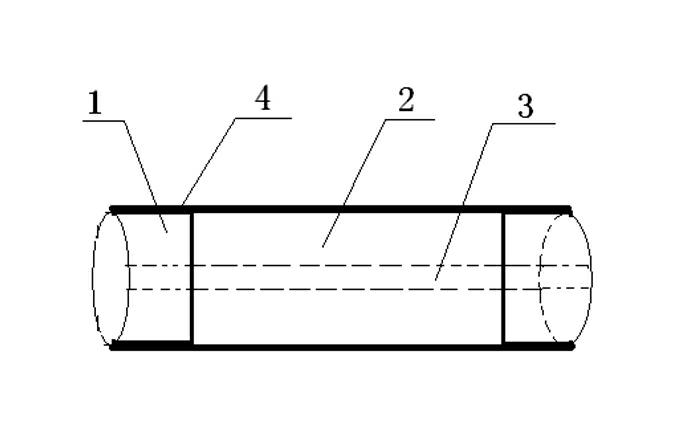

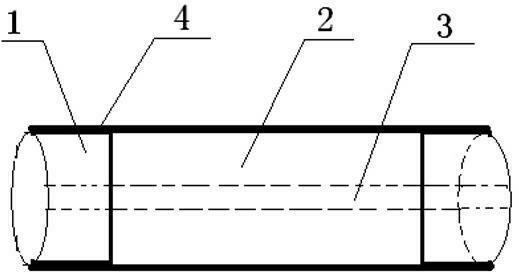

[0010] Such as figure 1 As shown, an electroslag remelted water-cooled cable includes a cable head 1, a wire 3 and an outer sheath 2, and is characterized in that there is a layer of asbestos 4 outside the outer sheath.

[0011] The water-cooled cable is easy to manufacture and has a limited increase in cost, but the service life is extended, and at the same time, water leakage accidents caused by damage to the water-cooled cable caused by heat sweeping radiation in the crystallizer are reduced or even avoided.

Embodiment 2

[0013] It is different from the electroslag remelted water-cooled cable in Embodiment 1 in that the asbestos layer 4 is composed of one or several layers of asbestos cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com