Anti-waterlogging distribution box and buried transformer station with same

A power distribution cabinet and buried technology, applied in the field of buried substations, can solve the problems of insufficient load reduction, inability to prevent flood disasters, and difficult to guarantee sealing quality, so as to effectively guarantee power supply safety and block external floods. , The effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

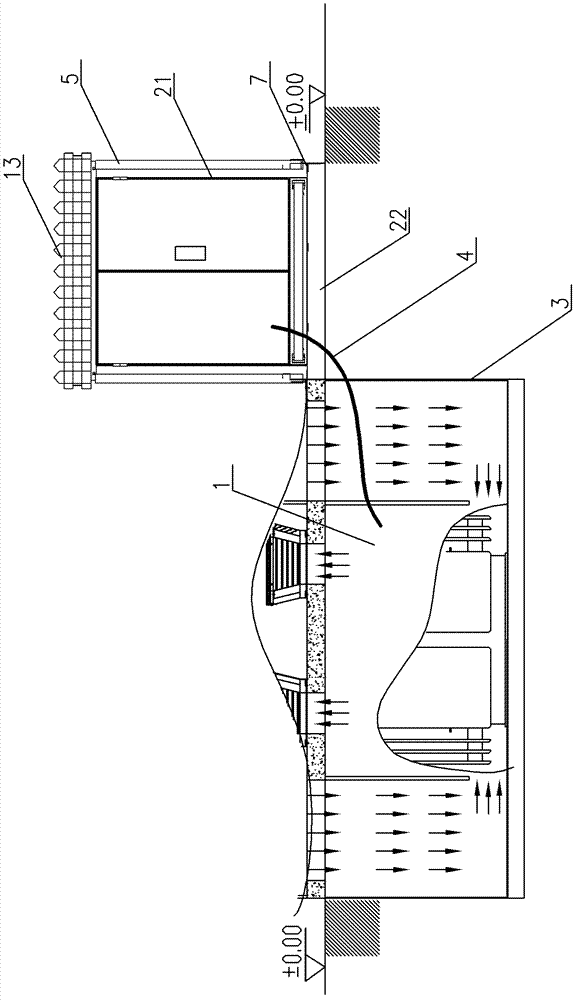

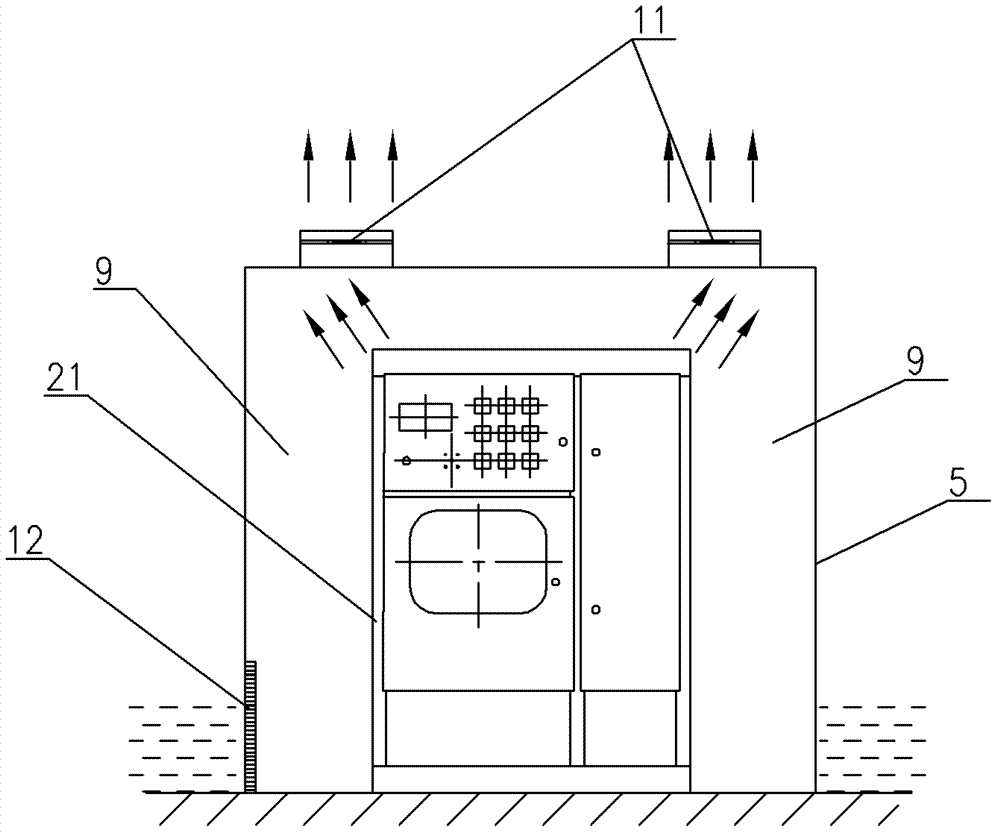

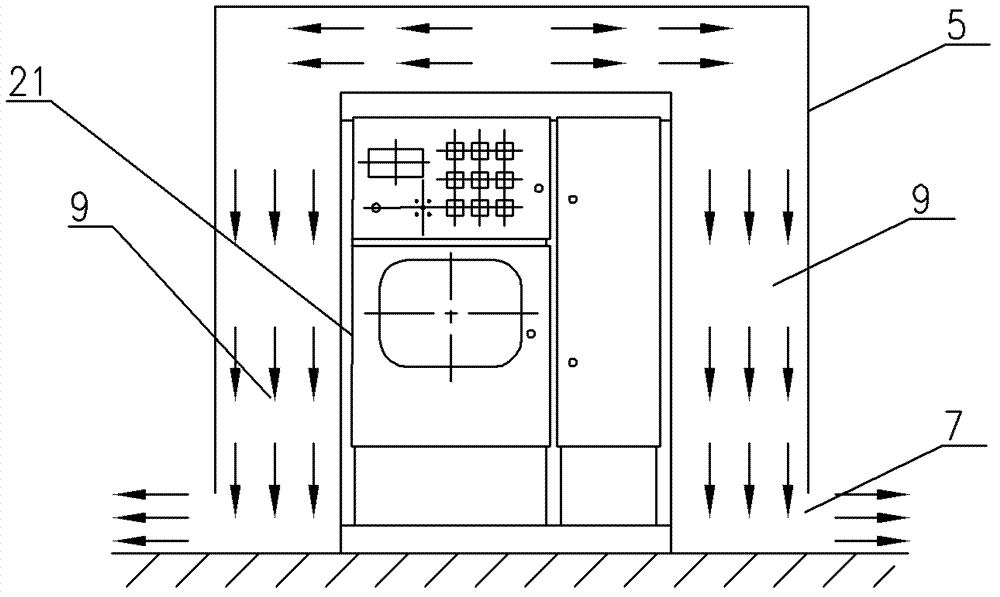

[0040] Such as Figure 1~3 As shown, it is a flood control buried substation of the present invention, including an underground transformer 1 that can be submerged in water, a power distribution cabinet, and a prefabricated pit foundation 3. The underground transformer 1 is arranged in the prefabricated pit foundation 3, and the underground The terminals of the type transformer 1 are connected to the power distribution cabinet through cables 4, wherein the power distribution cabinet includes a power distribution cabinet body 21 and a power distribution foundation 22 for installing the power distribution cabinet body 21, and the power distribution foundation 22 is higher than the ground surface The platform is equipped with a waterproof cover 5 outside the power distribution cabinet. The waterproof cover 5 is made of rigid materials. The waterproof cover 5 is a three-dimensional container with an opening on the bottom surface that is adapted to the contour of the power distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com