Oil magnetic-suspension double-stator high-efficiency motor

A double-stator, high-efficiency technology, applied in the direction of motors, electromechanical devices, electric vehicles, etc., can solve the problems of permanent magnet aging, high cost, large volume, etc., to achieve increased output power, huge economic benefits, energy saving and environmental protection, and guarantee maximum The effect of stabilization and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

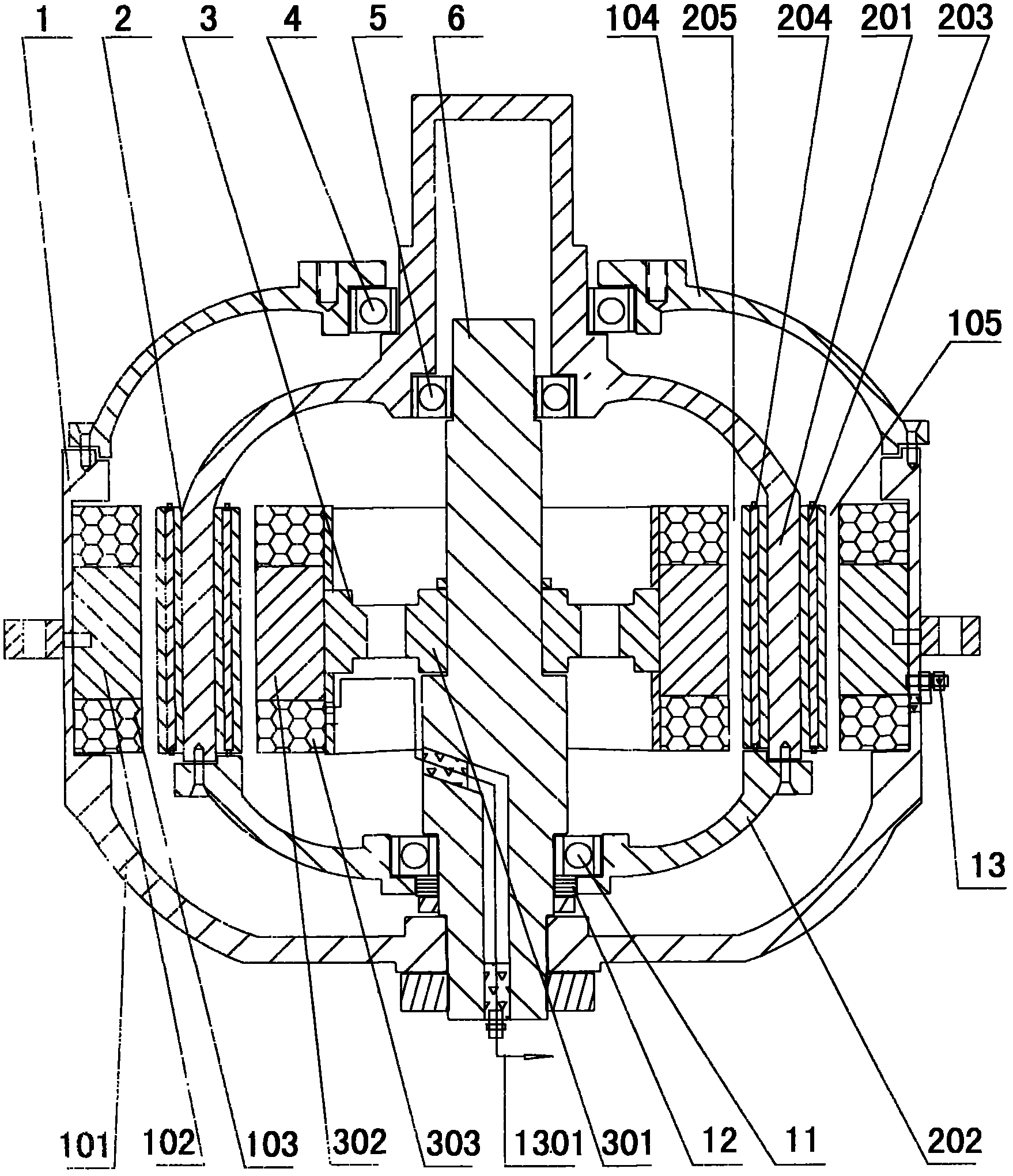

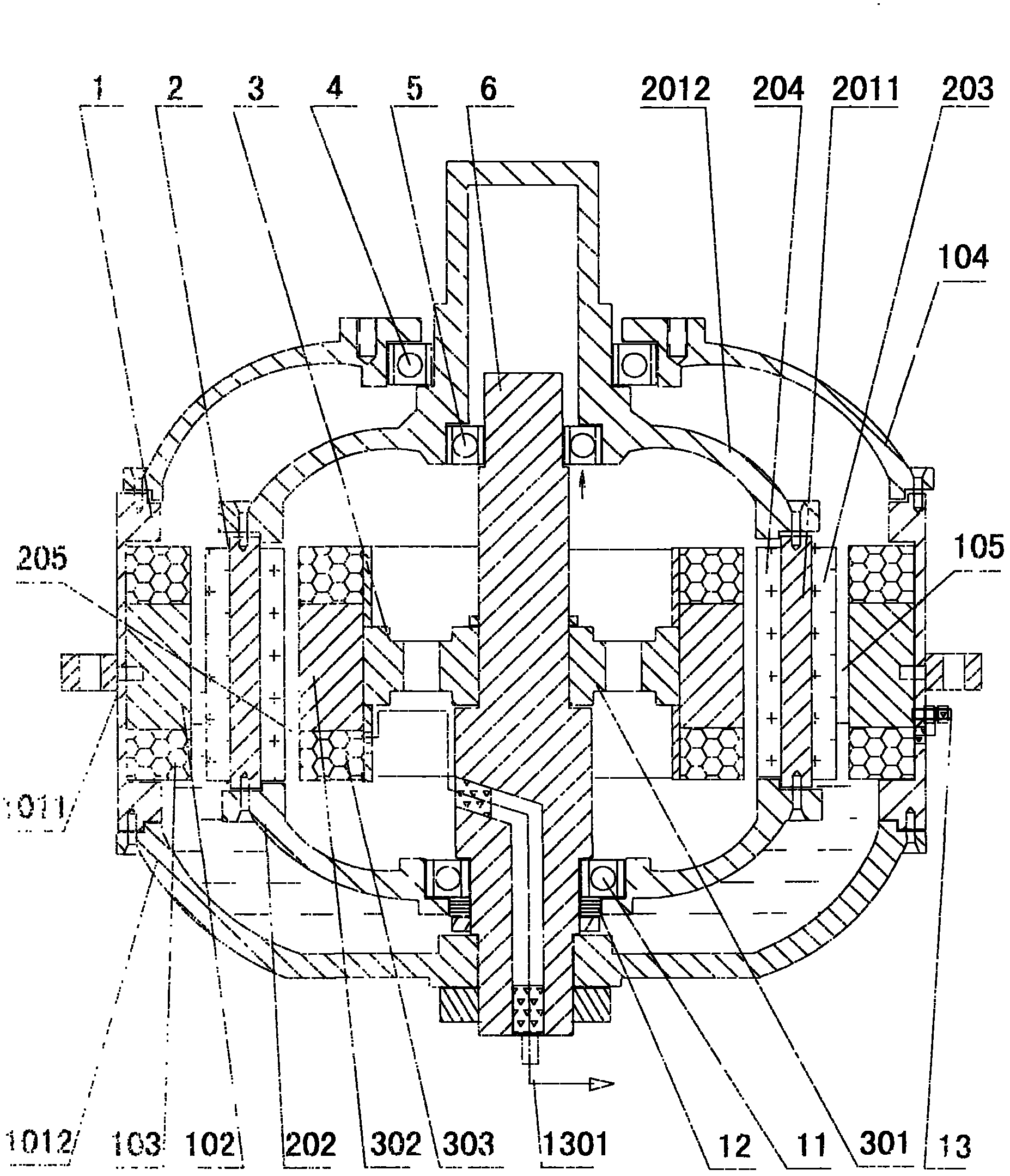

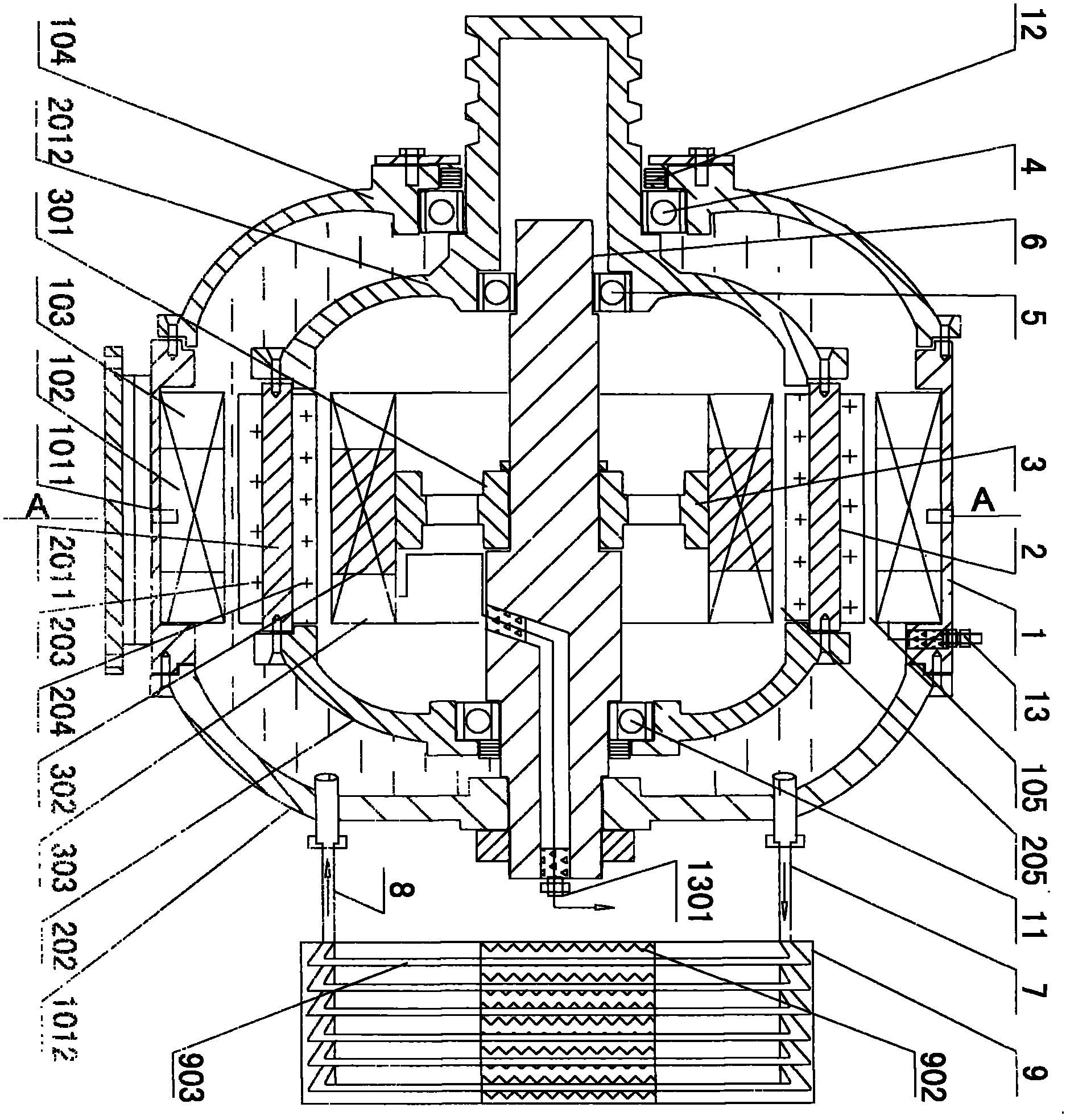

[0028] Example, with figure 1 : Structural cross-sectional schematic diagram of a dual-stator high-efficiency motor.

[0029] The front end of the stator housing 101 is connected with the stator end cover 104, which is fixed together by several bolts. The inner side of the stator housing 101 is provided with the iron core 102 and the winding 103 in the circumferential direction, the outer side of the stator housing is provided with a base, and the center of the stator housing The round hole is connected to the main shaft 6, and the wire is connected to the stator winding and passed through the pipeline in the casing to lead out to connect with the first terminal block 13 after the insulator is sealed; The round hole is fixed to the main shaft 6, and the second iron core 302 and the second stator winding 303 are arranged on the periphery. The wires connected to the second stator winding pass through the pipeline inside the main shaft and lead out to the second terminal block 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com