Maintenance tool special for dismounting and mounting double-bundle conductor clamp

A technology of double-split conductors and maintenance tools, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long bolting time, difficulty for one person, narrow space of climbing vehicles and aerial work platforms, etc., to improve power supply reliability, use and Easy to carry, beautiful appearance and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

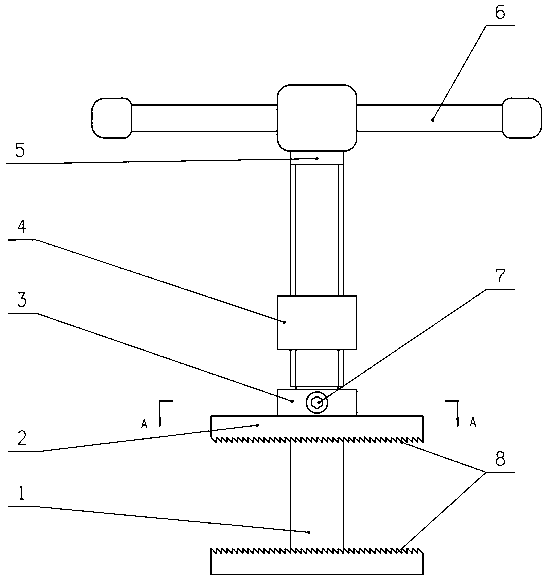

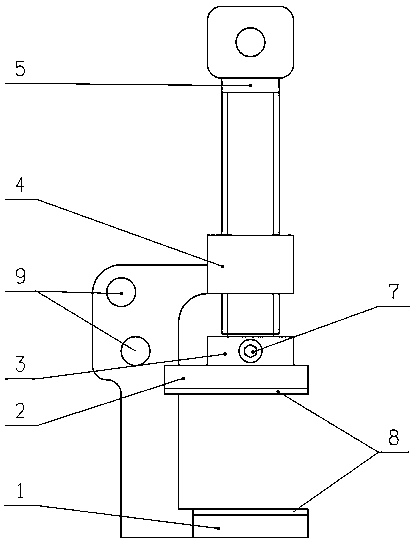

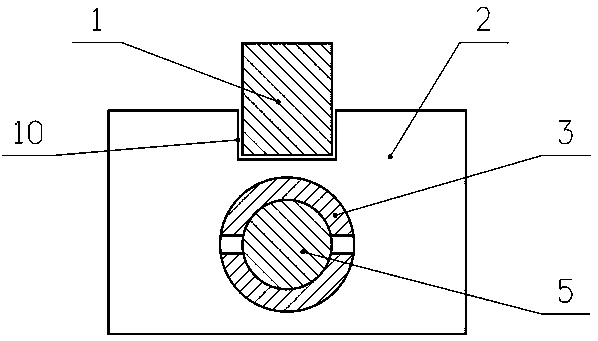

[0019] Such as figure 1 As shown, the special maintenance tool for disassembling and assembling a double-split wire clamp of the present invention includes a clamping element, a force element and a safety element. The clamping element is composed of a splint I and a splint II. The forcing elements are a screw rod and an afterburner rod, the afterburner rod is fixed at one end of the screw through an afterburner head, and the safety element is a safety pin and a safety belt.

[0020] The splint I is an L-shaped stainless steel plate, the length, width, and thickness of the base are respectively 80mm, 40mm and 10mm. The splint I is welded with an M20 nut on the top, and the back of the splint I is provided with two through holes. , The splint II is also a stainless steel plate, and an M20 screw is welded on the splint II, and the two sides of the screw are provided with anti-drop screws. The screw passes through the M20 nut on the upper part of the splint I and is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com