Multi-layer circuit board and electrostatic discharge protection structure

一种静电放电保护、多层电路板的技术,应用在电路静电放电保护、过电压保护、静电等方向,能够解决电路板设计尺寸越来越小、增加制造成本、增加电路复杂度等问题,达到良好静电防护效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

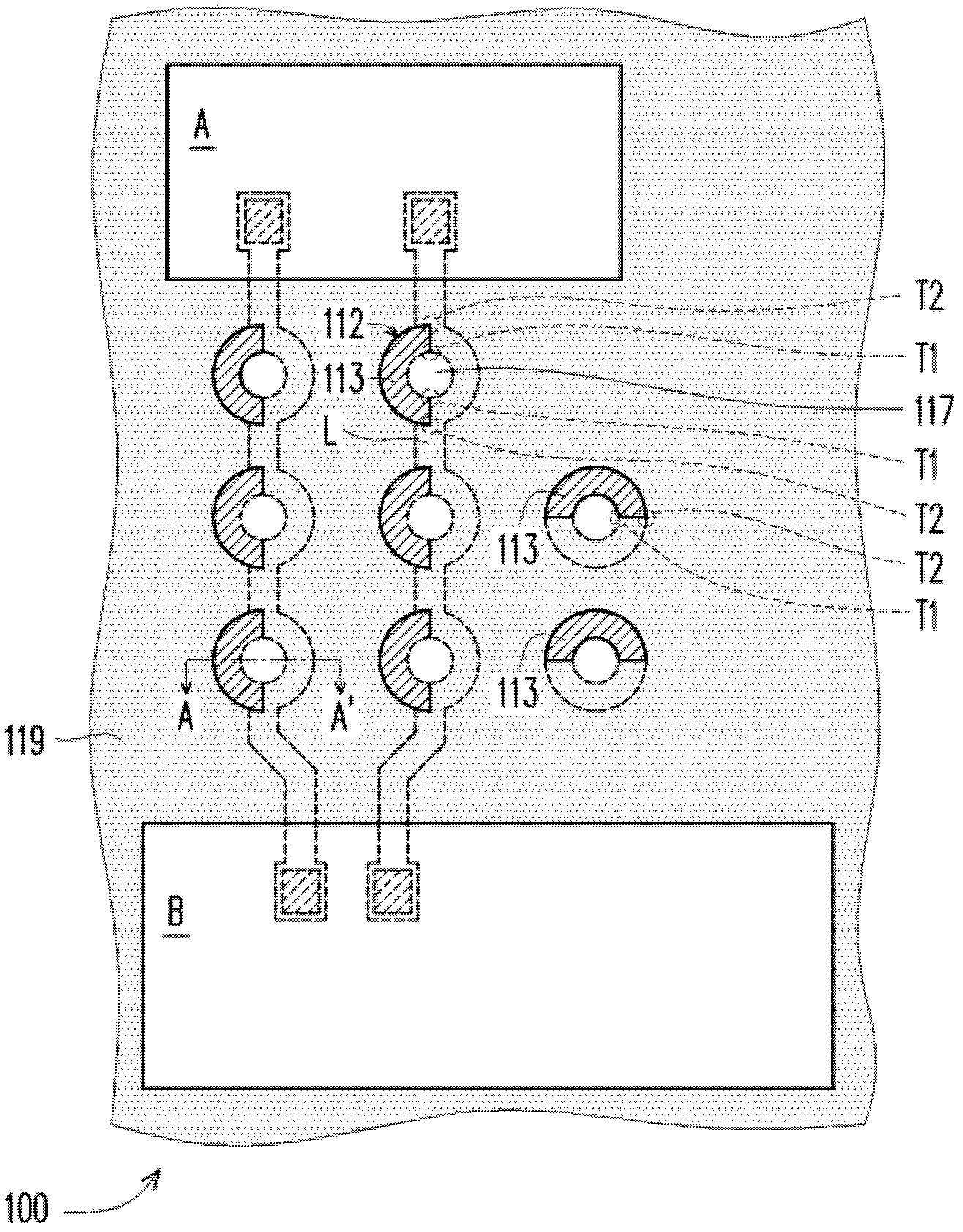

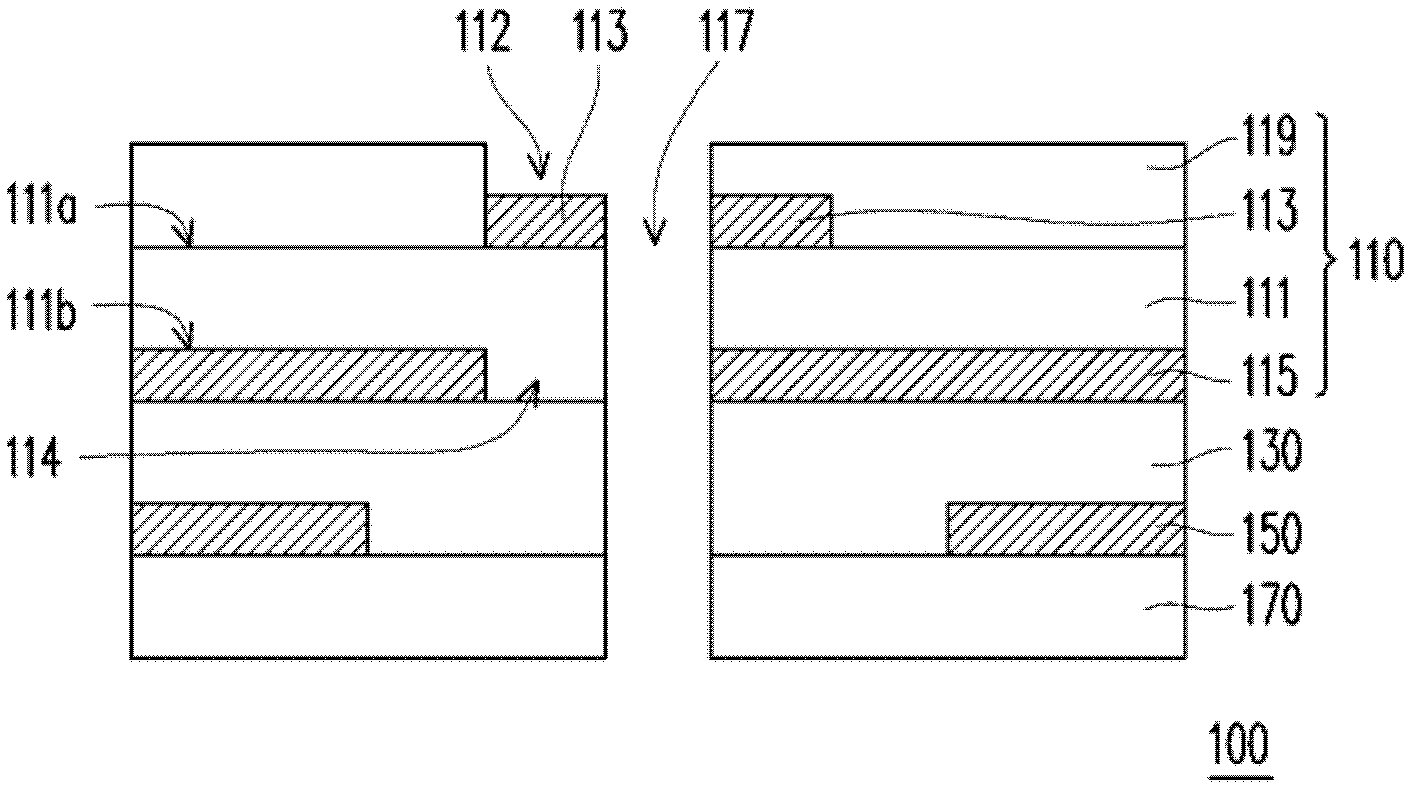

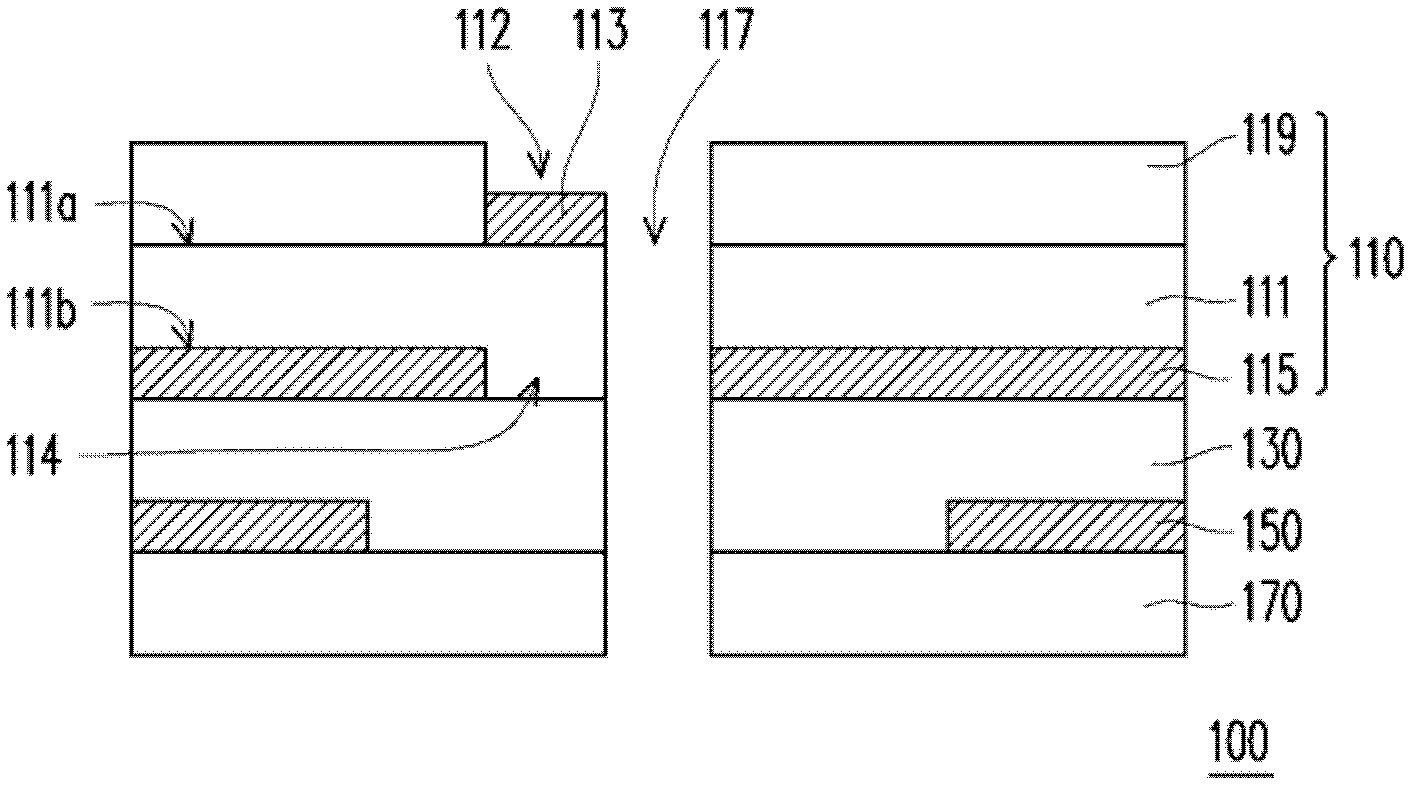

[0047] figure 1 It is a schematic top view of a multilayer circuit board according to an embodiment of the present invention, and Figure 2A for along figure 1 The cross-sectional schematic diagram of the A-A' section in . Please also refer to figure 1 and Figure 2A, the multilayer circuit board 100 of this embodiment is integrated with an electrostatic discharge protection structure 110 . In detail, the ESD protection structure 110 is integrated with the traces in the multilayer circuit board 100 to enhance the reliability of the multilayer circuit board 100 .

[0048] In this embodiment, the ESD protection structure 110 includes a first insulating layer 111 , a patterned conductive layer 113 and an ESD release layer 115 . When the ESD protection structure 110 is integrated into the multilayer circuit board 100 , the core layer, the laminated dielectric layer or the build-up dielectric layer in the multilayer circuit board 100 up dielectric layer) can be used as the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com