Sintered coupling ring

A technology of clutch teeth and wedge-shaped ends, which is applied to clutches, mechanically driven clutches, vehicle components, etc., can solve problems such as stopper breakage and manufacturing costs, and achieve the effects of improving bearing capacity, simplifying manufacturing requirements, and reducing the risk of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

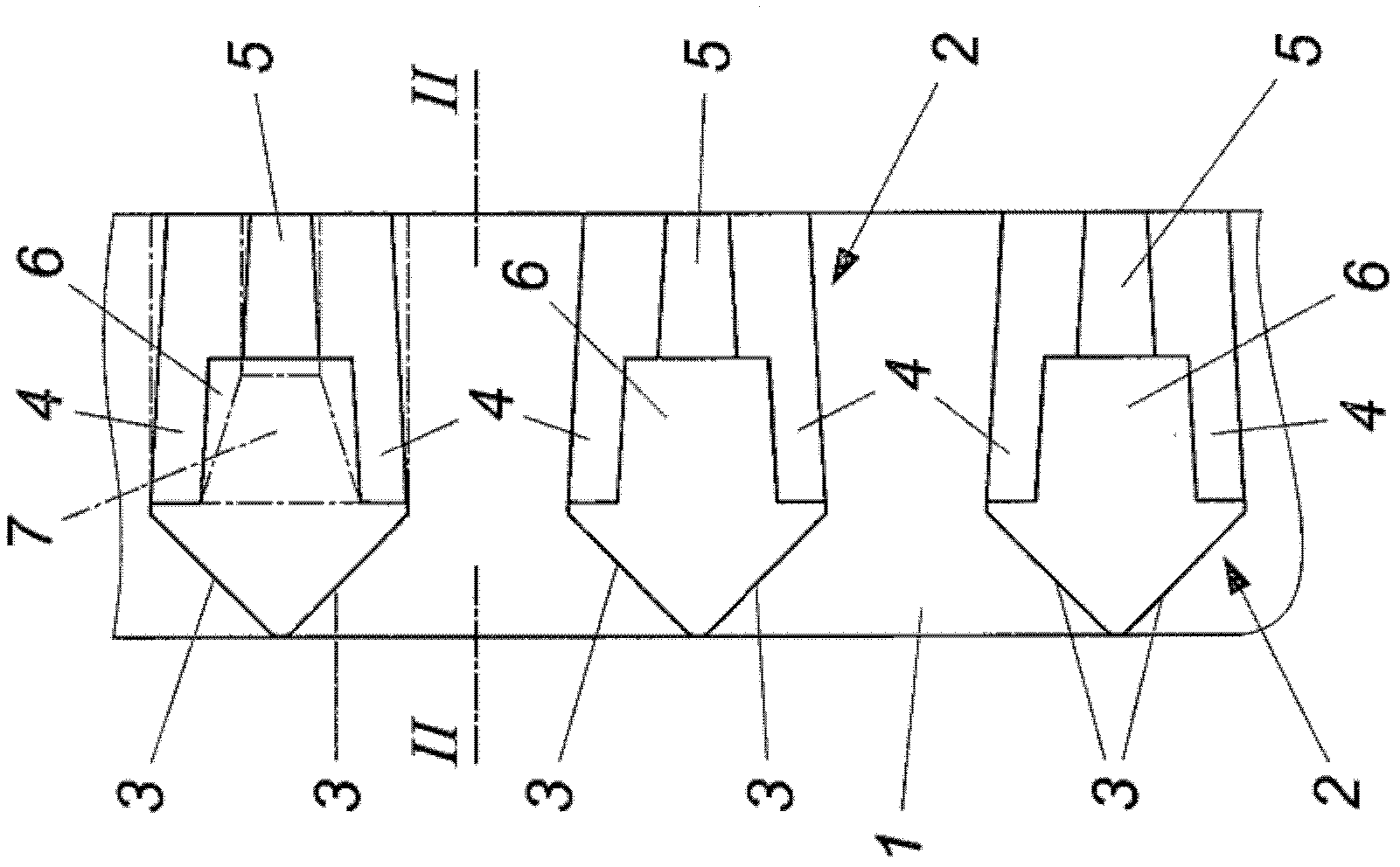

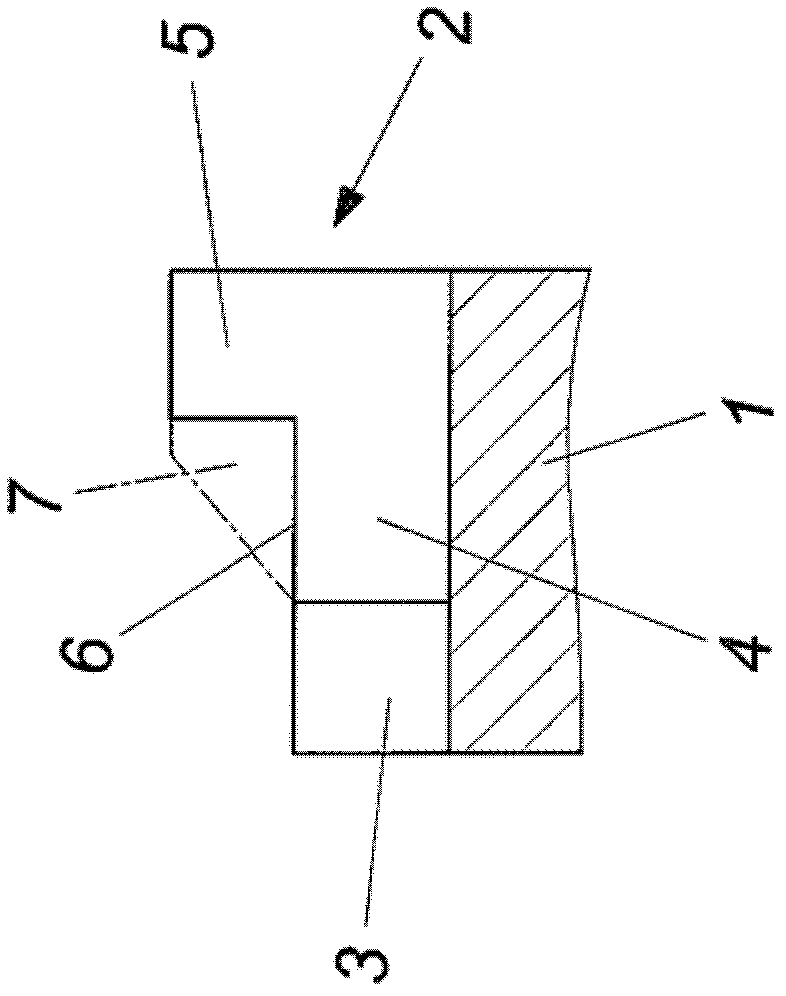

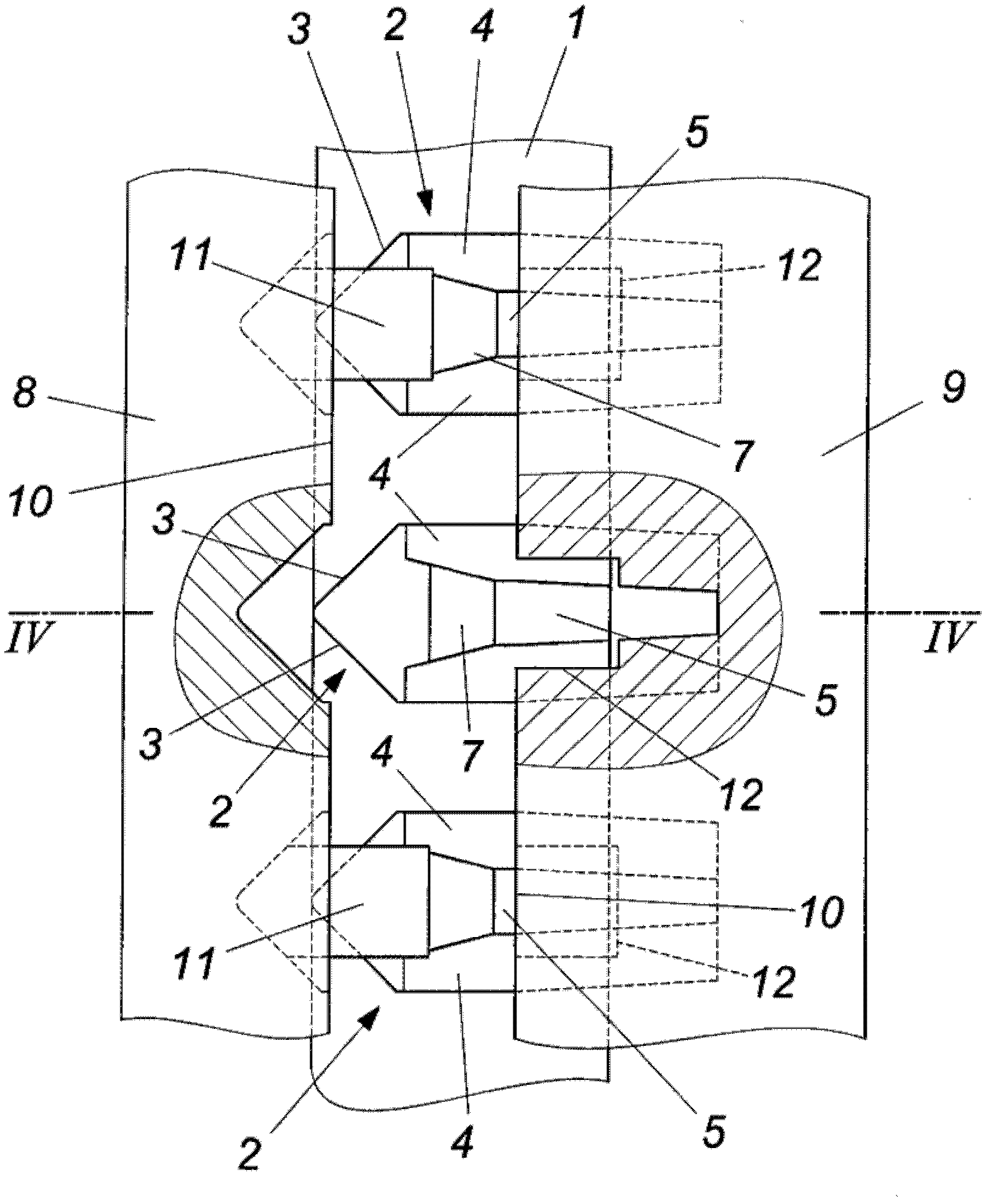

[0014] according to figure 1 with figure 2 The sintered clutch ring 1 has a ring gear consisting of clutch teeth 2 which are formed on the end face of the wedge-shaped end face 3 . A setback flank 4 adjoins this end face 3 . In order to limit the axial movement of the selector sleeve interacting with the clutch ring 1, the clutch tooth 2 is provided with a stop 5 on the end side opposite the wedge-shaped end face 3, as in particular from figure 2 It can be seen that the stop protrudes radially beyond the tooth tip 6 .

[0015] In order to manufacture such a clutch ring 1, a powder blank whose clutch teeth 2 are configured with axially parallel tooth surfaces (such as figure 1 shown by the clutch teeth shown in dotted lines). Furthermore, the stop 5 is extruded and sintered with an allowance 7, which in figure 2 is also shown with a dotted line. When calibrating the sintered molded body, on the one hand the tooth flank indentation is molded and compressed, and on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com