Front axle carrier having integrated steering housing

A technology of front axle bracket and steering box, which is applied in the direction of vehicle components, substructure, transportation and packaging, etc., can solve the problems of high material cost and manufacturing cost, achieve high bending strength, avoid supply consumption and assembly consumption, and save The effect of component costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

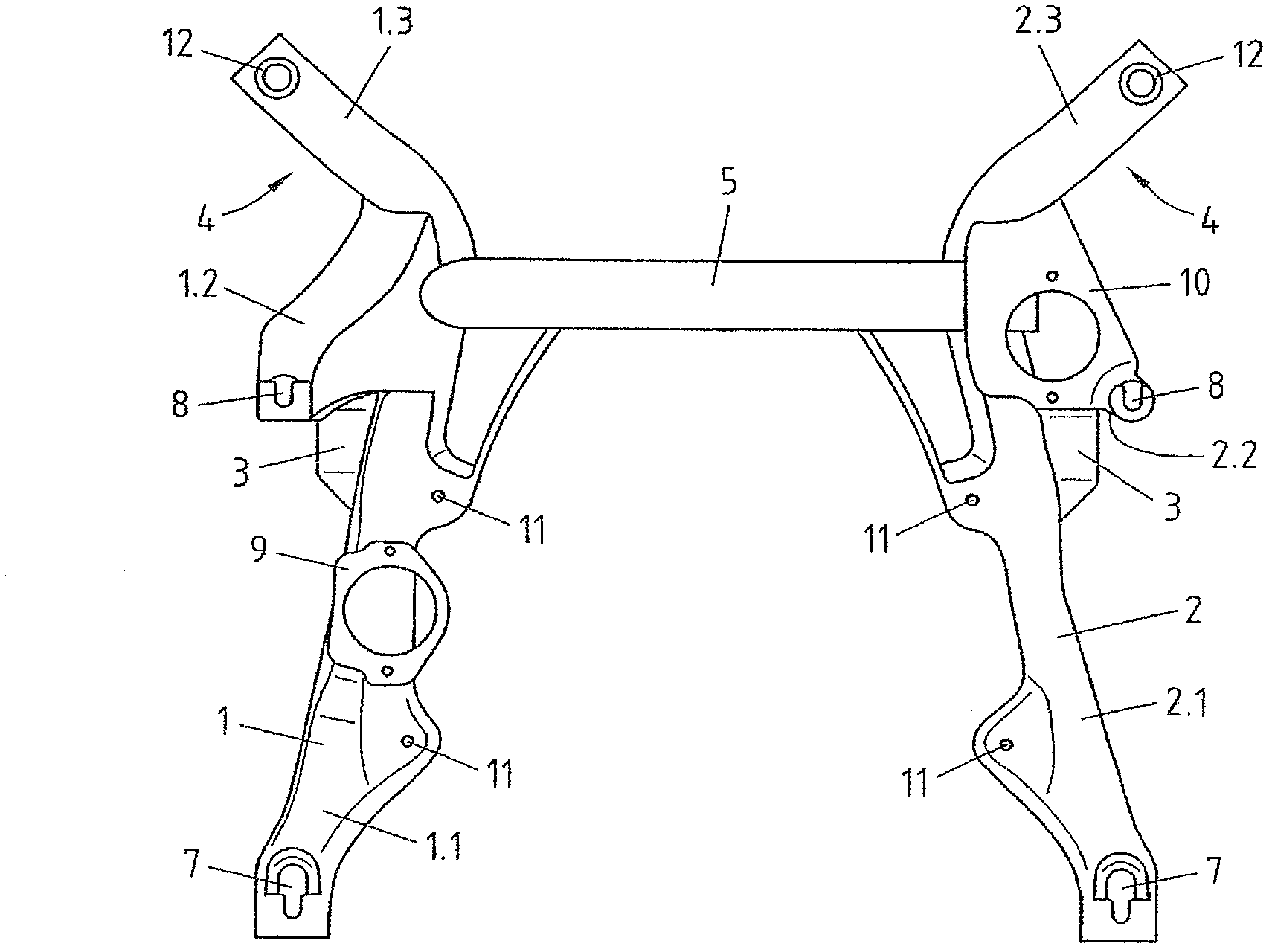

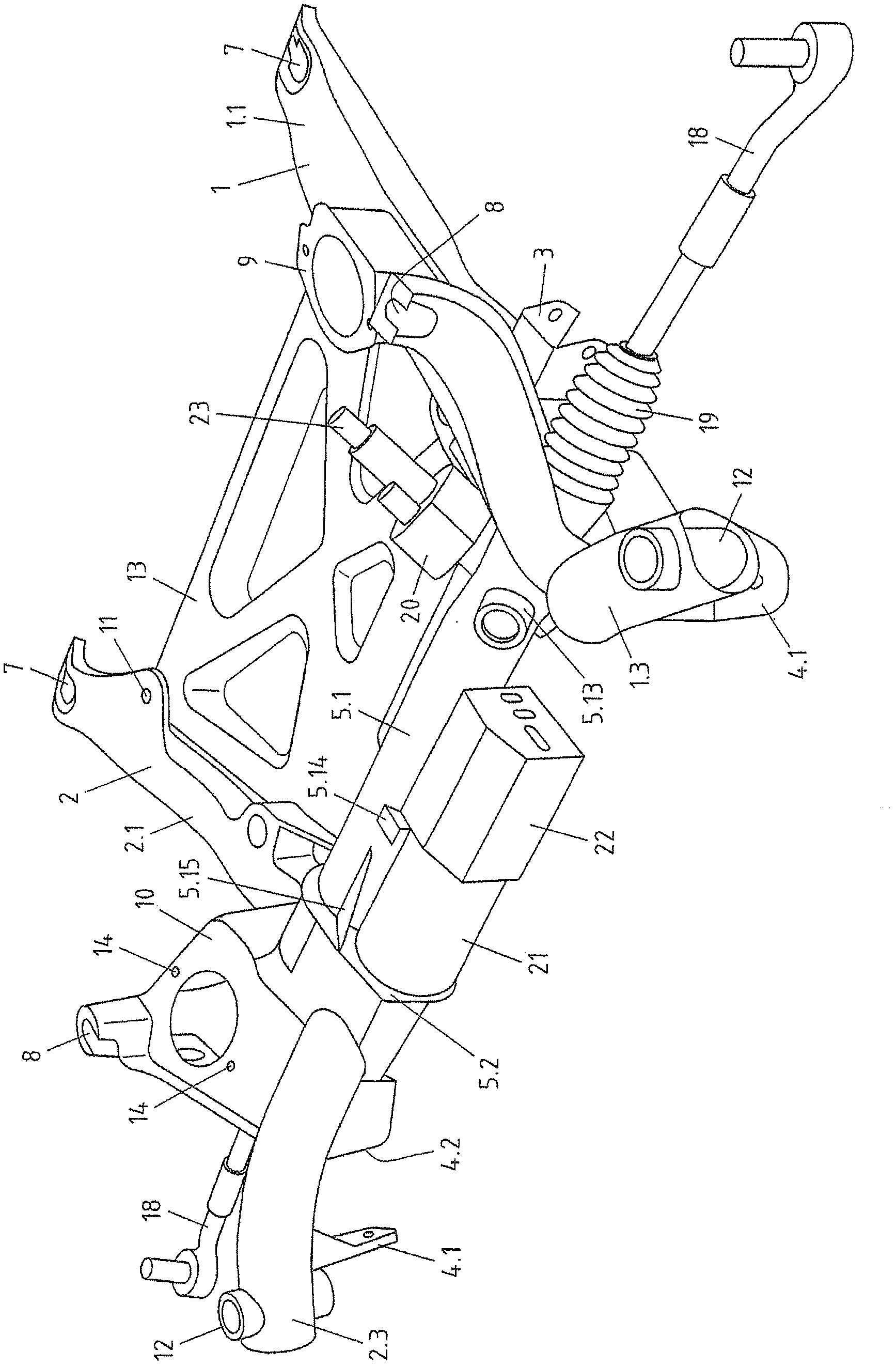

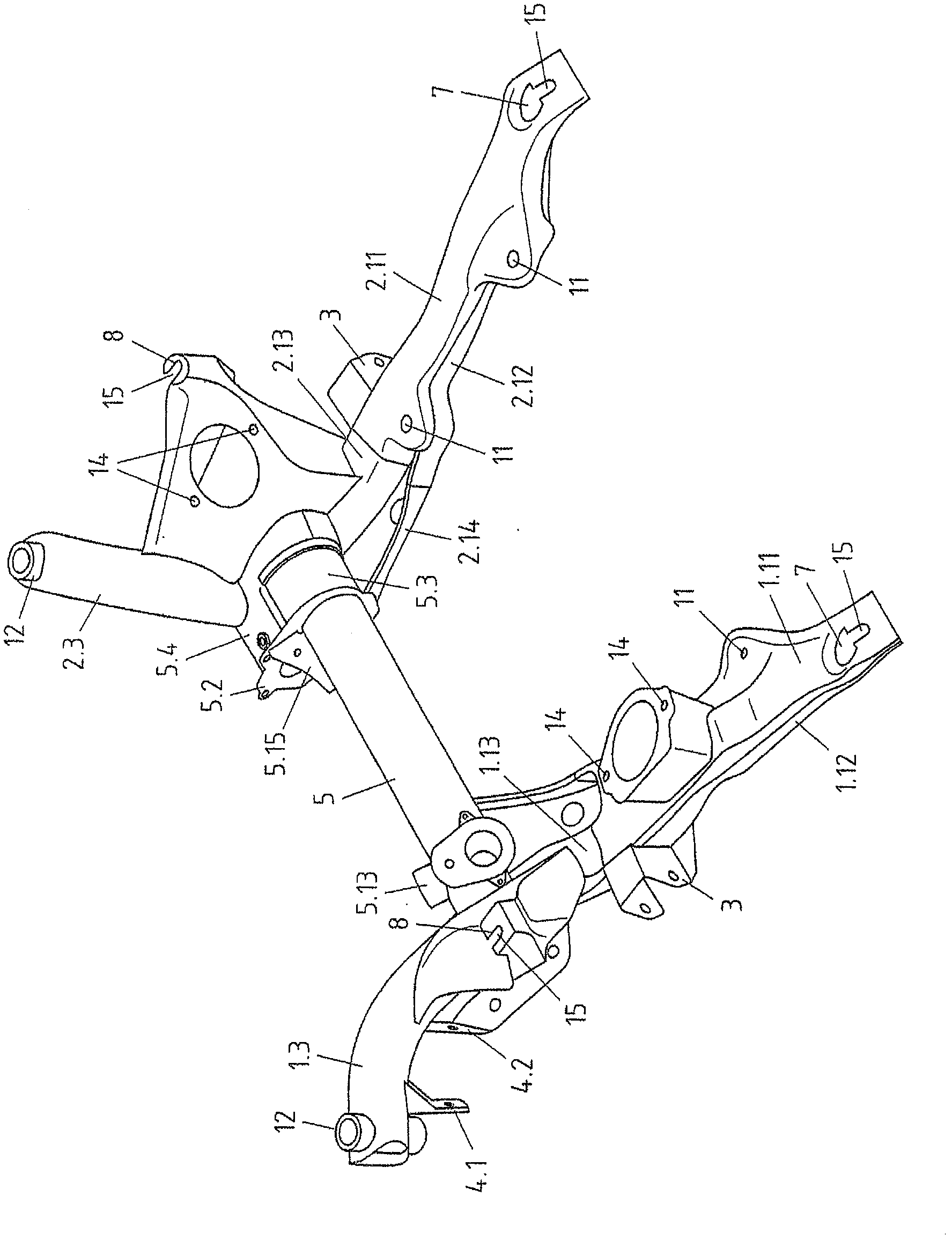

[0029] figure 1A first exemplary embodiment of the inventive front axle carrier with integrated steering box is shown by way of example. The front axle bracket consists of longitudinal brackets 1, 2, fastening elements 3, 4 for the positioning of the wheel guide elements. The longitudinal brackets 1, 2 are connected to the steering box 5 by welding, and the steering box simultaneously functions as a transverse bracket. The longitudinal brackets 1, 2 are formed in the rear section from sheet steel shells 1.1, 1.2, 2.1, 2.2 welded together. These sheet steel shells have openings 7 , 8 for bolting or screwing the front axle carrier to the motor vehicle body. The rear and central openings 7 , 8 have notches on their retaining faces, which limit damage to the connecting parts in the event of a crash. The sheet steel profiles 1.2, 2.2 with centrally located openings 8 or fastenings are mounted on the longitudinal brackets 1, 2 and welded to them. Furthermore, supports or fixings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com