Intermediate film for laminated glass, and laminated glass

A technology of laminated glass and interlayer film, applied in glass/slag layered products, layered products, transportation and packaging, etc., can solve problems such as insufficient absorption of near-infrared rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

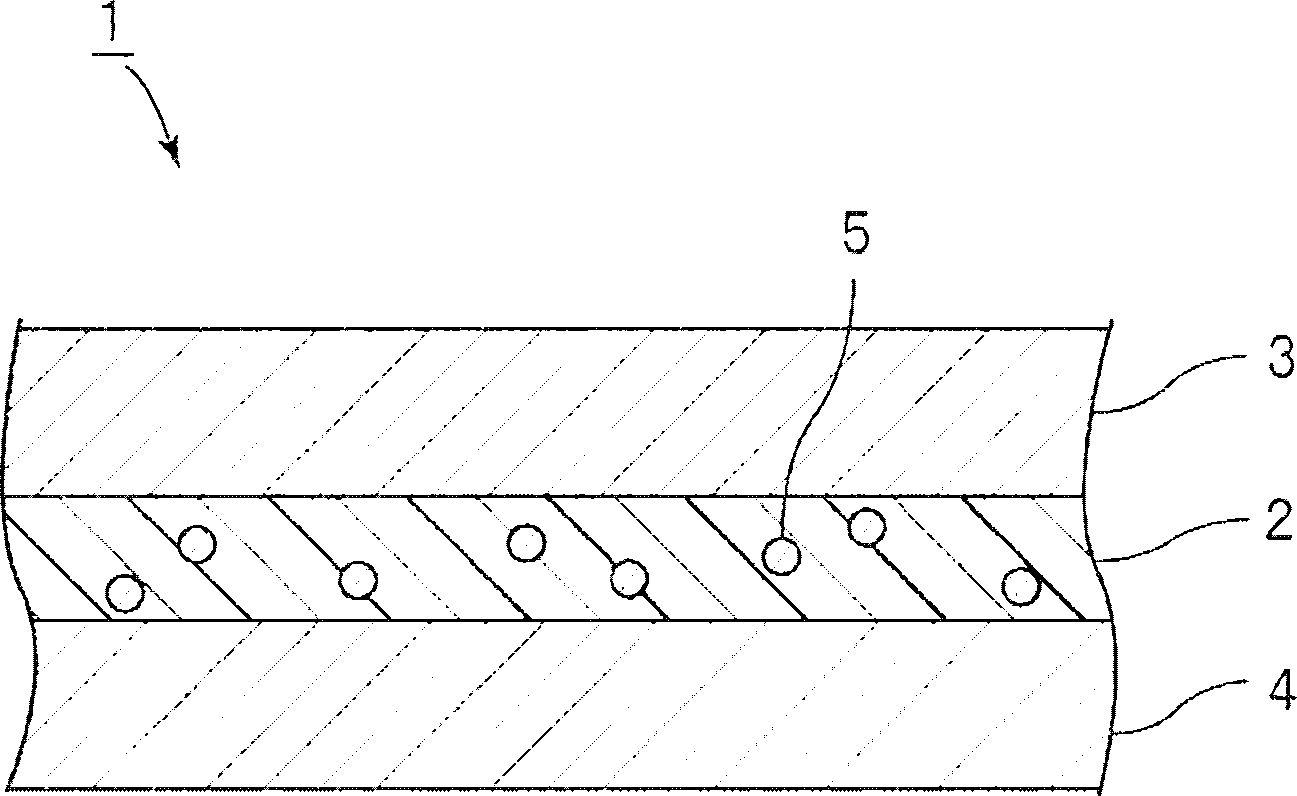

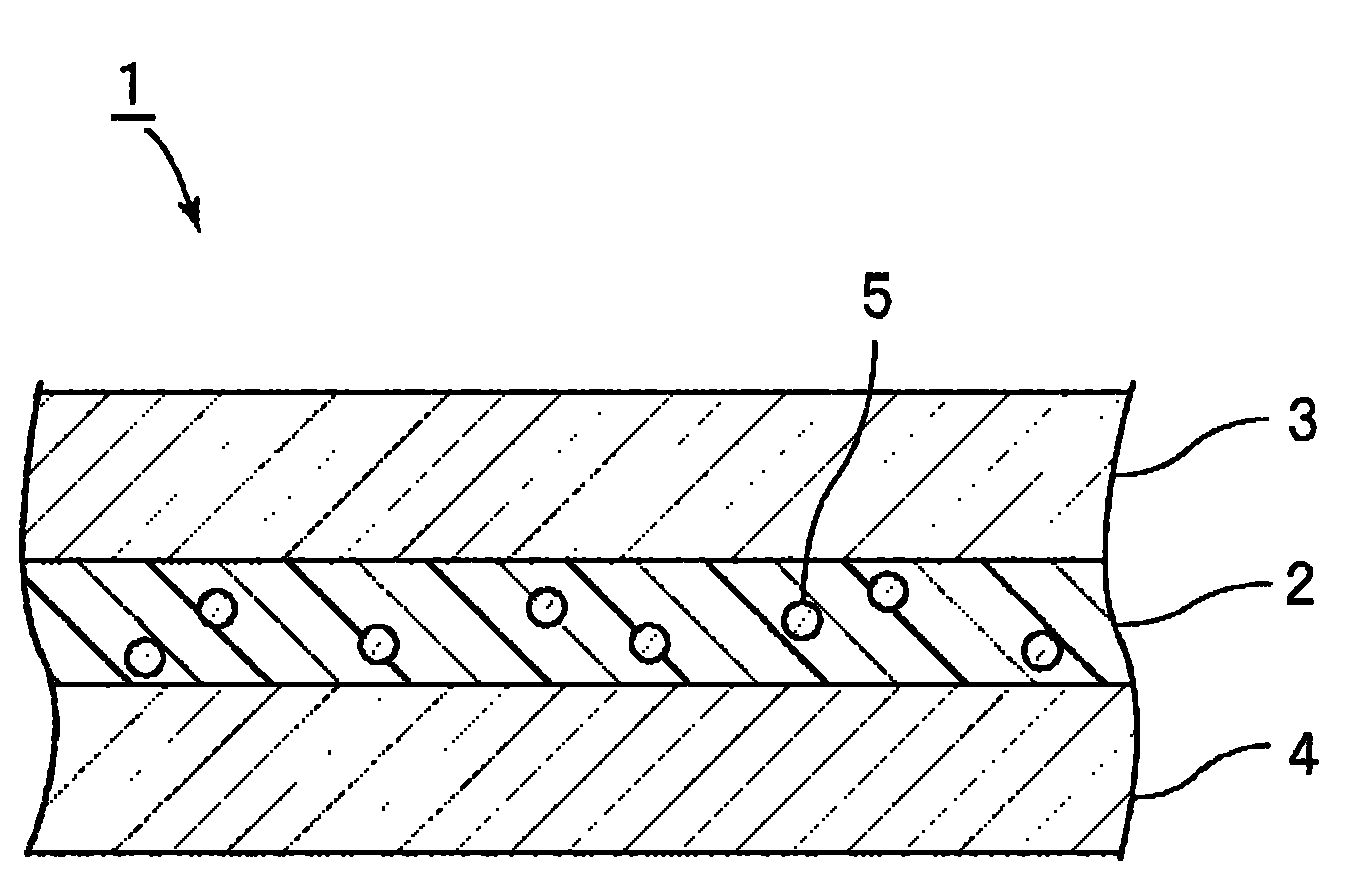

Image

Examples

Embodiment 1

[0109] (1) Preparation of dispersion liquid

[0110] 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO), 0.28 parts by weight of ITO particles (manufactured by Mitsubishi Materials Co., Ltd.), 0.004 parts by weight of naphthalocyanine compound ("FF-IRSORB203" made by Fujifilm Co., Ltd.) Parts by weight, and 0.234 parts by weight of yellow dye (anthraquinone dye, maximum absorption wavelength 450nm, "ORACET Yellow GHS" manufactured by Ciba Japan Co., Ltd.) are mixed, and after adding a phosphoric acid ester compound as a dispersant, pass through a horizontal bead mill Mix to obtain a mixed solution. Then, 0.1 part by weight of acetylacetone was added to the mixed liquid with stirring to prepare a dispersion liquid. The volume average particle diameter of the ITO particles in the dispersion liquid was 35 nm. The naphthalocyanine compound ("FF-IRSORB 203" manufactured by Fujifilm Corporation) contained copper.

[0111] (2) Production of interlayer film for lami...

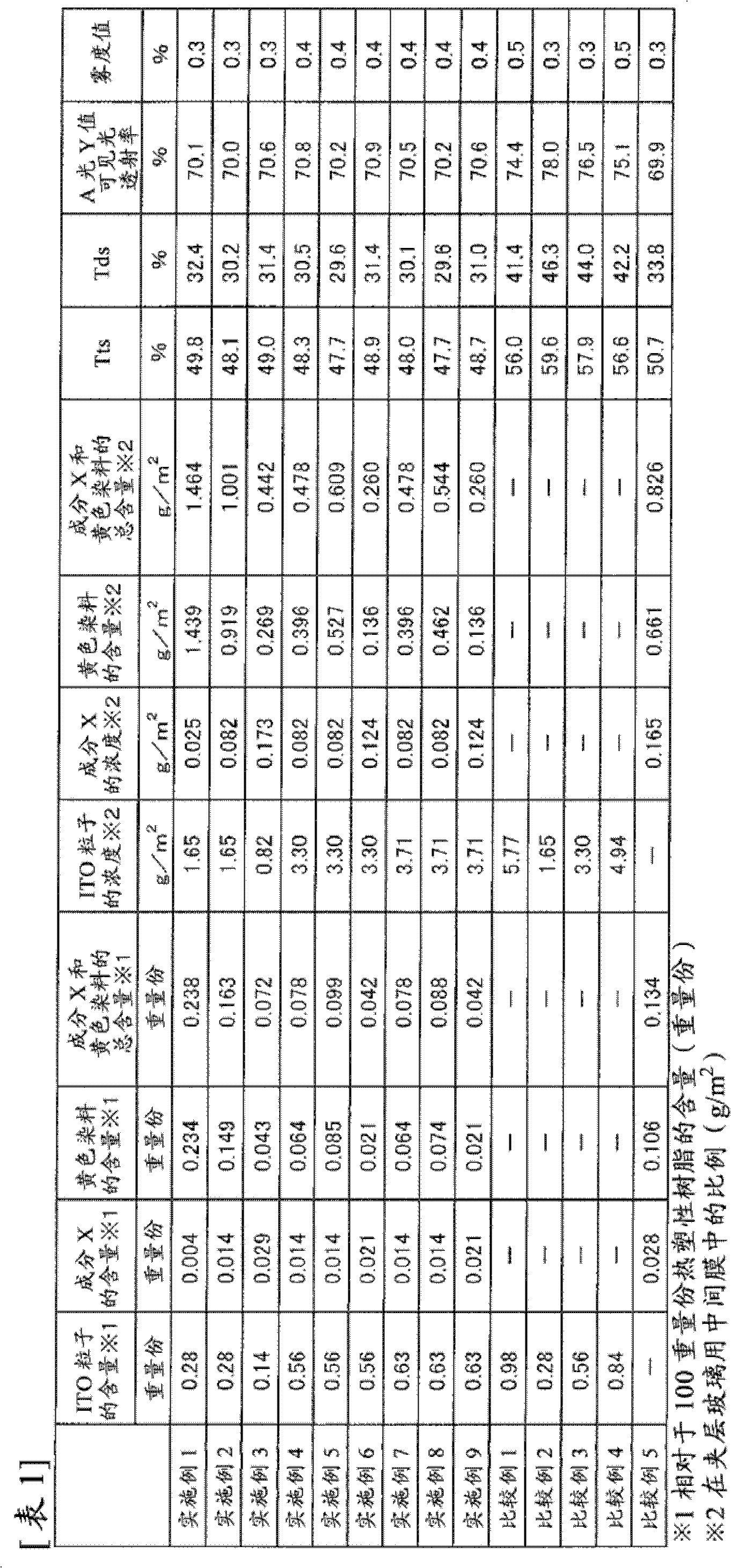

Embodiment 2~9 and comparative example 1~5

[0117] Dispersions, interlayer films for laminated glass, and laminated glasses 1 and 2 were prepared as in Example 1 except that the composition of the interlayer film for laminated glass was changed as shown in Table 1 below.

[0118] (Evaluation)

[0119] (1) Determination of Tts and Tds (Solar Direct Transmittance)

[0120] The above-mentioned Tts and the above-mentioned Tds of the obtained laminated glass 1 were measured according to the measurement method prescribed by the above-mentioned Cool Cars Standards. Specifically, the above Tts and the above Tds were measured with a spectrophotometer (“U-4100” manufactured by Hitachi-hitec Co., Ltd.) in accordance with JIS R3106 (1998).

[0121] (2) Determination of visible light transmittance

[0122] The visible light transmittance at a wavelength of 380 to 780 nm of the obtained laminated glass 1 was measured using a spectrophotometer ("U-4100" manufactured by Hitachi-hitec Co., Ltd.) in accordance with JIS R3211 (1998).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com