Near-infrared reflective film and near-infrared reflector provided with same

A near-infrared, reflective film technology, used in instruments, building components, layered products, etc., can solve problems such as fracture, insufficient flexibility, and poor production efficiency, and achieve high visible light transmittance, excellent flexibility, and manufacturing. Cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

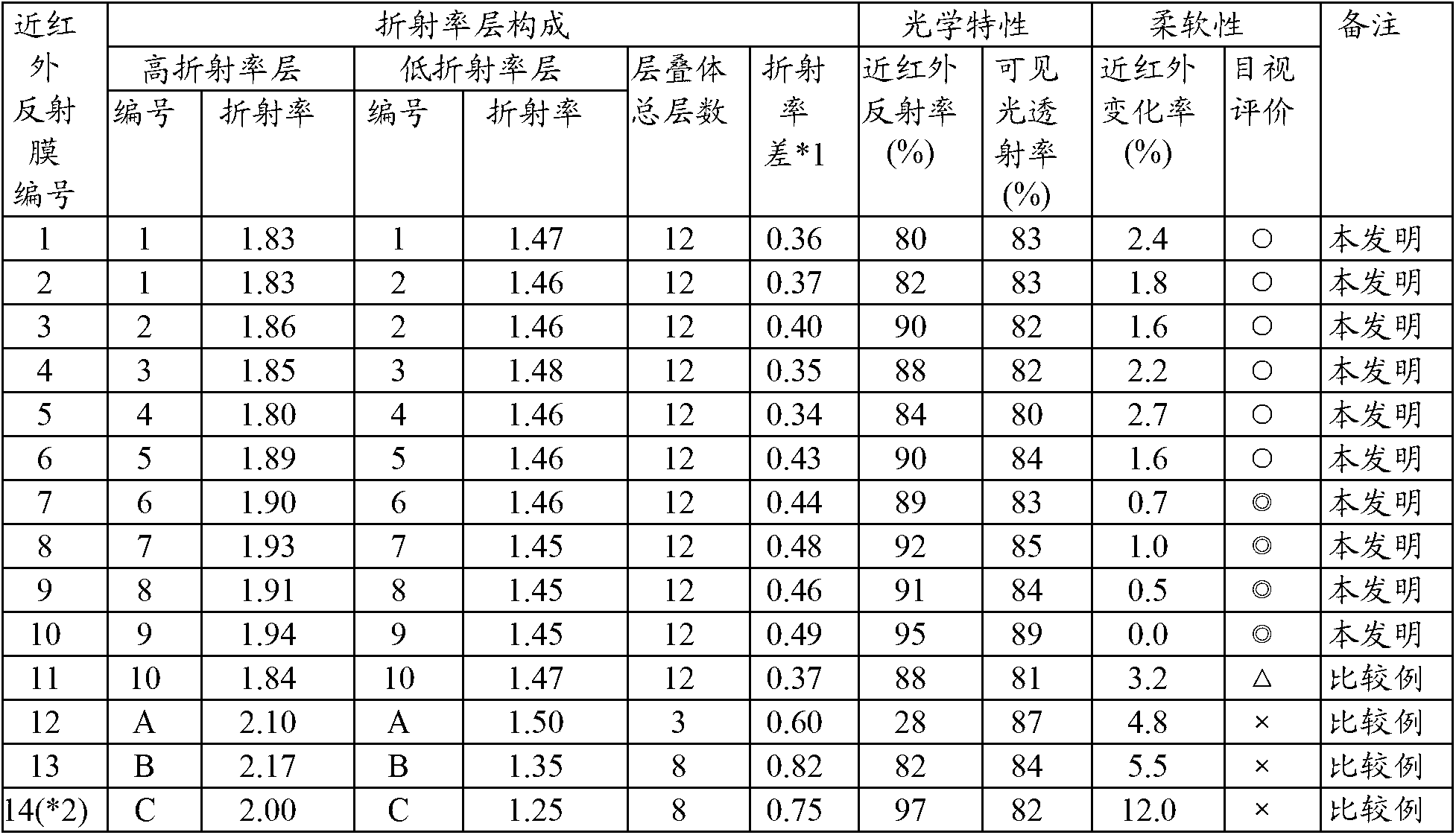

[0107] "Fabrication of near-infrared reflective film"

[0108] [Preparation of sample 1]

[0109] (Formation of High Refractive Index Layer 1)

[0110] Disperse 100 parts of zirconia sol (Nanoyouth ZR30-AR manufactured by Nissan Chemical) as a metal oxide in a solution obtained by dissolving 5 parts of guar gum and 5 parts of polyvinyl alcohol (PVA203 manufactured by Kuraray) in 100 parts of water , to prepare high refractive index layer coating solution 1.

[0111] Next, using the high-refractive-index layer coating solution 1, the high-refractive-index layer 1 was coated on a polyethylene terephthalate film with a thickness of 50 μm using a wire bar under the condition that the dry film thickness was 135 nm. Drying is performed to form the high refractive index layer 1 .

[0112] (Formation of Low Refractive Index Layer 1)

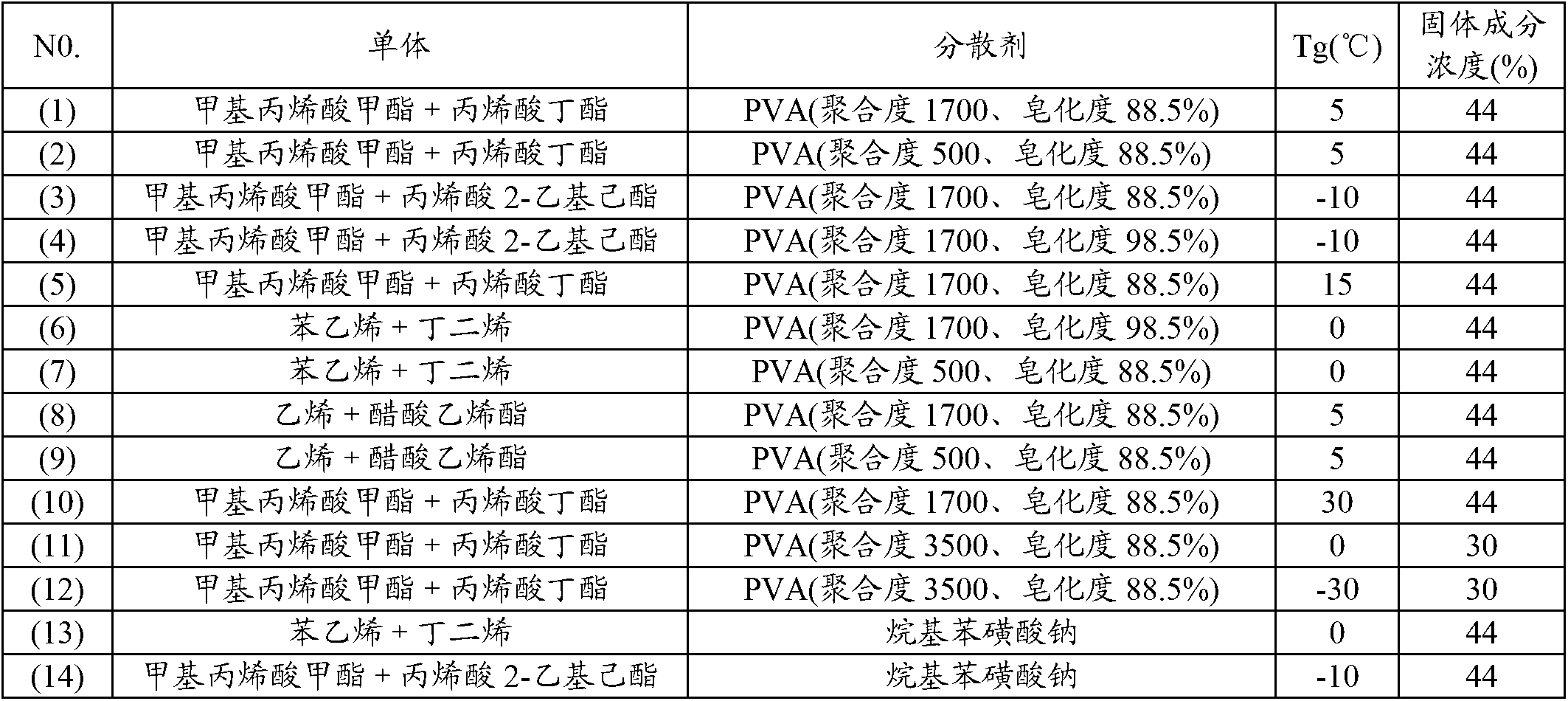

[0113] 100 parts of colloidal silica (Snowtex OS manufactured by Nissan Chemical) as a metal oxide is dispersed in a solution of 12 parts of polyvinyl...

Embodiment 2

[0201] [Production of near-infrared reflector 1]

[0202] The near-infrared reflector 1 was produced using the near-infrared reflective film of sample 8 produced in Example 1. The near-infrared reflective film of sample 8 was bonded to a transparent acrylic resin plate with a thickness of 5 mm and 20 cm×20 cm with an acrylic adhesive to produce a near-infrared reflector 1 .

[0203] [Production of near-infrared reflector 2]

[0204] The near-infrared reflector 2 was produced using the near-infrared reflective film of sample 8 described in Example 1. Two sheets of plate glass with a thickness of 2 mm and 20 cm x 20 cm were prepared, and a laminate in which polyvinyl butyral with a thickness of 0.5 mm was arranged on both sides of the near-infrared reflective film of Sample 8 was sandwiched between the two sheets of glass and Pressurization and heat treatment were performed to manufacture the near-infrared reflector 2 as laminated glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com