Intermediate Film For Laminated Glass, And Laminated Glass

A technology of laminated glass and interlayer film, which is applied in the direction of glass/slag layered products, layered products, transportation and packaging, etc., and can solve the problem of not being able to fully absorb near-infrared rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] (1) Preparation of dispersion liquid

[0111] 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO), 0.28 parts by weight of ITO particles (manufactured by Mitsubishi Materials), and 0.004 naphthalocyanine compound (“FF-IRSORB203” manufactured by Fujifilm) Parts by weight and 0.234 parts by weight of a yellow dye (anthraquinone dye, maximum absorption wavelength 450 nm, "ORACET Yellow GHS" manufactured by Ciba Japan) were mixed, and after adding a phosphoric acid ester compound as a dispersant, the mixture was passed through a horizontal bead mill. Mixing was performed to obtain a mixed solution. Then, 0.1 part by weight of acetylacetone was added to the mixed liquid under stirring to prepare a dispersion liquid. The volume average particle diameter of the ITO particles in the dispersion liquid was 35 nm. In addition, the naphthalocyanine compound ("FF-IRSORB203" by Fujifilm company) contains copper.

[0112] (2) Production of interlayer film for laminat...

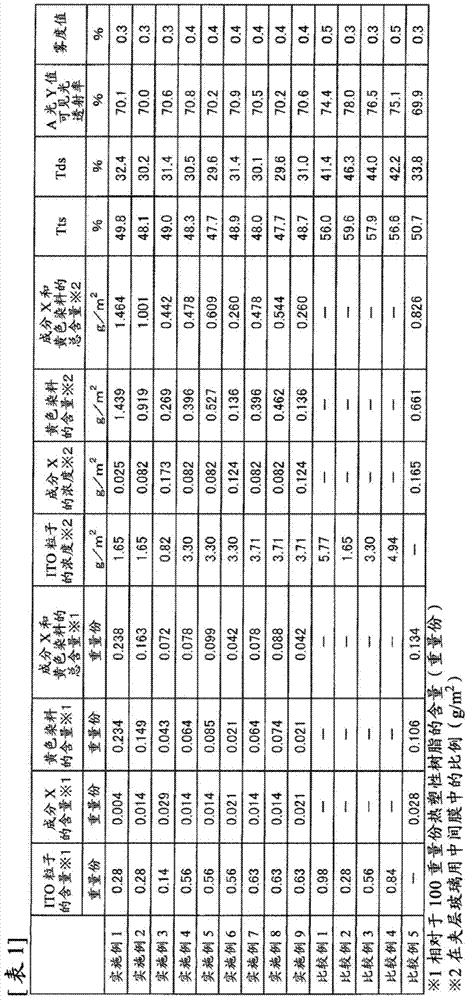

Embodiment 2~9 and comparative example 1~5

[0118] A dispersion liquid, an interlayer film for laminated glass, and laminated glasses 1 and 2 were produced as in Example 1, except that the composition of the interlayer film for laminated glass was changed as shown in Table 1 below.

[0119] (Evaluation)

[0120] (1) Measurement of Tts and Tds (Solar Direct Transmittance)

[0121] The above-mentioned Tts and the above-mentioned Tds of the obtained laminated glass 1 were measured according to the measurement methods prescribed by the above-mentioned Cool Cars Standards. Specifically, the above-mentioned Tts and the above-mentioned Tds were measured according to JIS R3106 (1998) using a spectrophotometer (“U-4100” manufactured by Hitachi-hitec).

[0122] (2) Measurement of visible light transmittance

[0123] The above-mentioned visible light transmittance of the obtained laminated glass 1 at a wavelength of 380 to 780 nm was measured with a spectrophotometer (“U-4100” manufactured by Hitachi-hitec) in accordance with JI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com