A composite film used for a solar cell and a preparation method therefor and application thereof

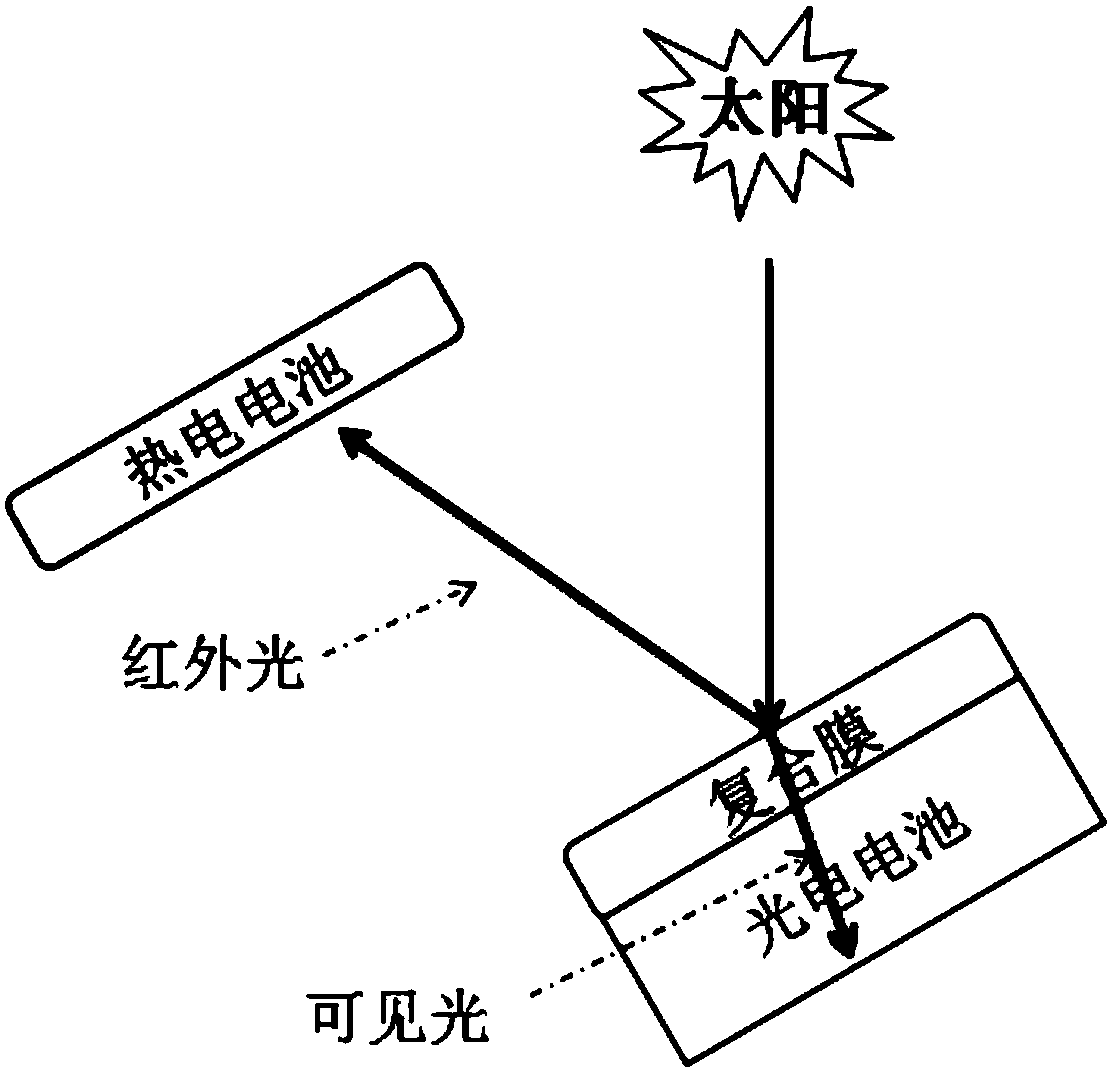

A technology of solar cells and composite films, applied in the field of composite films, can solve the problems of low reflection utilization rate of solar cells and cannot meet the needs of photovoltaic cells and thermoelectric cells at the same time, and achieve the effect of easy control of process conditions and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

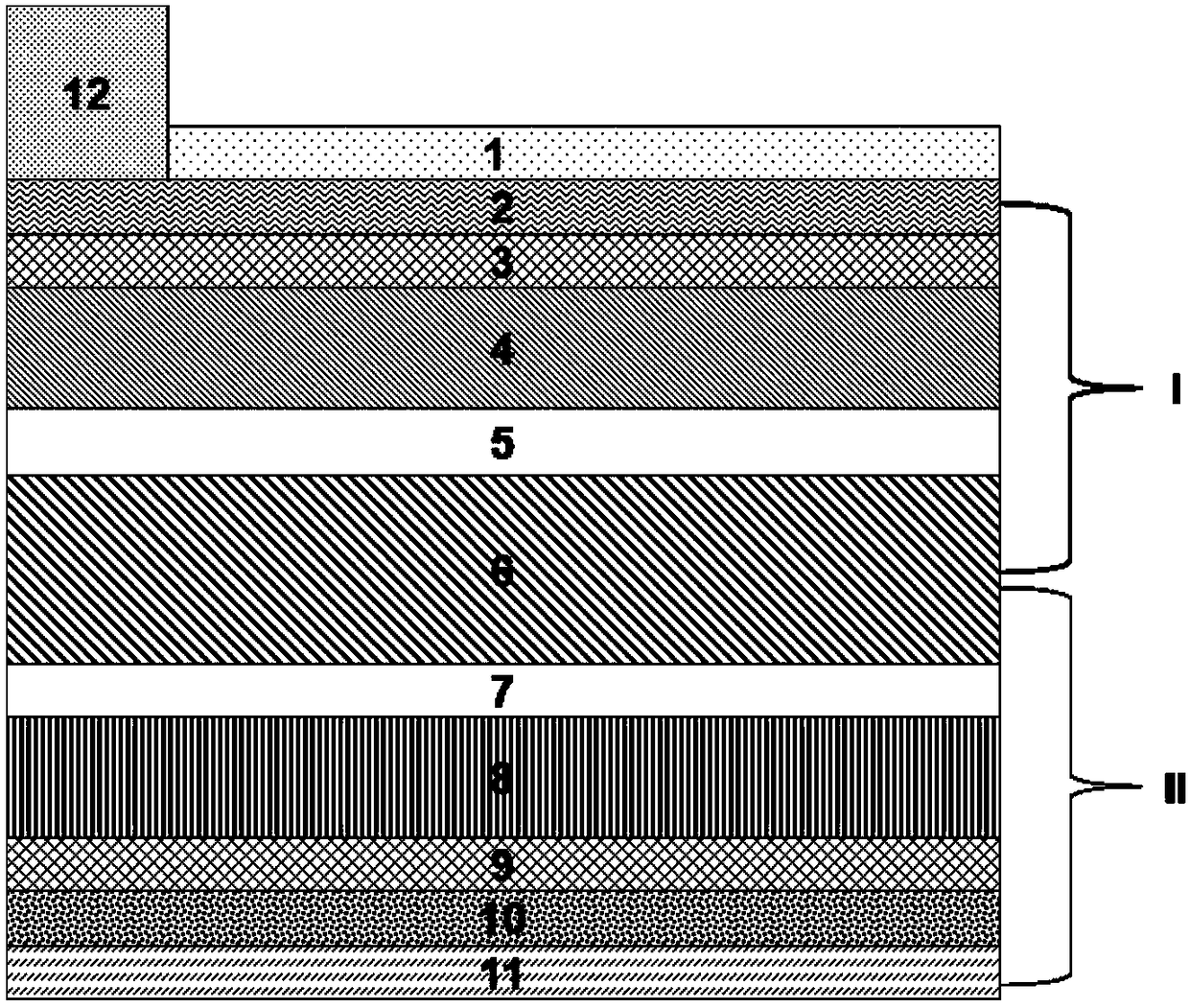

[0035] Select copper indium gallium selenide solar cells as photovoltaic cells:

[0036] (1) The process of preparing AZO thin films by magnetron sputtering is as follows:

[0037] Using the glass slide as the substrate, ultrasonically cleaned with analytically pure acetone, analytically pure alcohol and deionized water in turn, dried with pure nitrogen, and then put the substrate into the magnetron sputtering reaction chamber, and used radio frequency magnetron sputtering. The method grows AZO thin films on the substrate, the substrate temperature is 180℃ during sputtering, and the sputtering power density is 5W / cm 2 , the sputtering pressure is 0.8Pa, the sputtering protective gas is argon, and the sputtering time is 20min. The thickness of the obtained AZO thin film was 800 nm.

[0038] (2) The process of preparing Ag thin films by magnetron sputtering is as follows:

[0039] Ag film was grown on the prepared AZO film, the substrate temperature was room temperature durin...

Embodiment 2

[0045] Selection of perovskite solar cells as photovoltaic cells:

[0046] (1) The process of preparing AZO thin films by magnetron sputtering is as follows:

[0047]Using the glass slide as the substrate, ultrasonically cleaned with analytically pure acetone, analytically pure alcohol and deionized water in turn, dried with pure nitrogen, and then put the substrate into the magnetron sputtering reaction chamber, and used radio frequency magnetron sputtering. Methods The AZO film was grown on the substrate. The substrate temperature was 200℃, the sputtering power density was 5W / cm2, the sputtering pressure was 0.9Pa, the sputtering protective gas was argon, and the sputtering time was 15min. The thickness of the obtained AZO thin film was 400 nm.

[0048] (2) The process of preparing Ag thin films by magnetron sputtering is as follows:

[0049] Ag film was grown on the prepared AZO film. During sputtering, the substrate temperature was room temperature, the sputtering power ...

Embodiment 3

[0055] Select copper indium gallium selenide solar cells as photovoltaic cells:

[0056] (1) The process of preparing AZO thin films by magnetron sputtering is as follows:

[0057] Using the glass slide as the substrate, ultrasonically cleaned with analytically pure acetone, analytically pure alcohol and deionized water in turn, dried with pure nitrogen, and then put the substrate into the magnetron sputtering reaction chamber, and used radio frequency magnetron sputtering. Methods AZO thin films were grown on the substrate. The substrate temperature was 230℃, the sputtering power density was 5W / cm2, the sputtering pressure was 0.3Pa, the sputtering protective gas was argon, and the sputtering time was 10min. The thickness of the obtained AZO thin film was 600 nm.

[0058] (2) The process of preparing Ag thin films by magnetron sputtering is as follows:

[0059] Ag film was grown on the prepared AZO film. The substrate temperature was room temperature during sputtering, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com