Method for preparing hollow spheres and films surrounded by VO2 nanosheets

A nanosheet and VO2 technology, applied in the direction of vanadium oxide, etc., can solve the problems of difficult preparation of particles, low sensitivity, large hysteresis width of small particles, etc., and achieve balance of visible light transmittance and light modulation ability, and enhanced sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

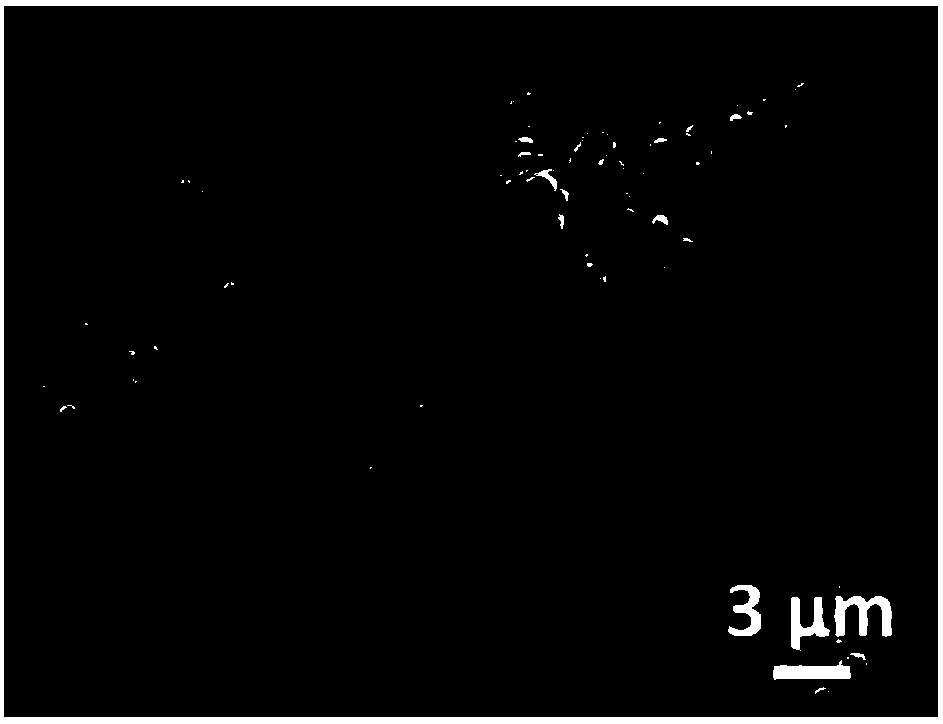

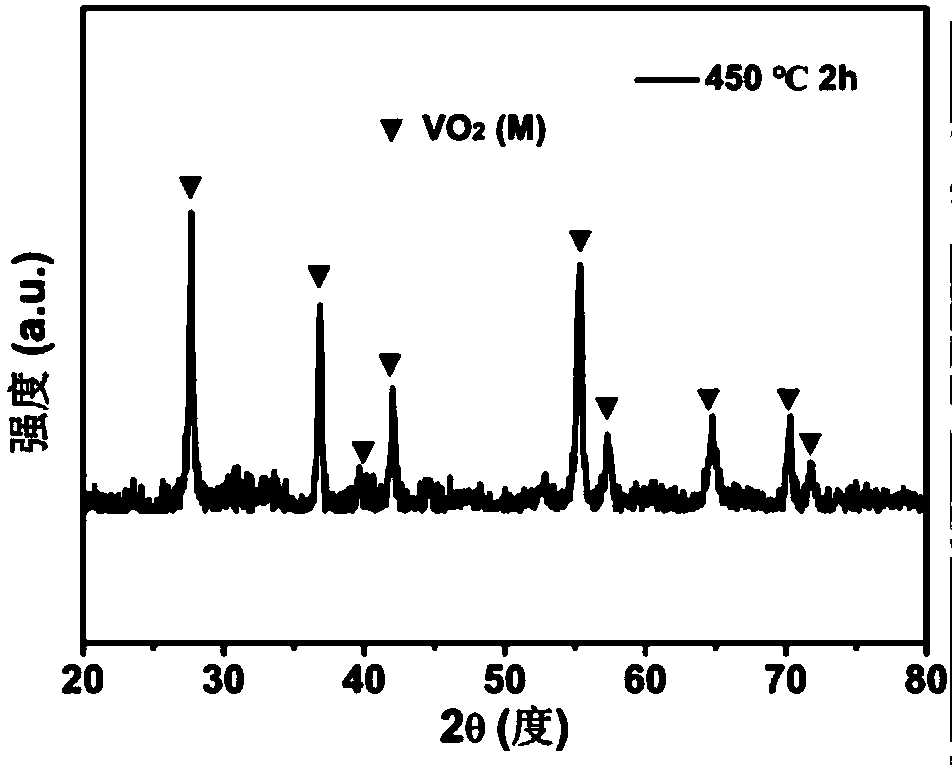

Image

Examples

Embodiment 1

[0052] 1) Configure a mixed solution of ethanol and deionized water with a volume ratio of 4:1, and add ammonium metavanadate, the concentration of ammonium metavanadate in the solution is 0.05mol / L; crush the mixed solution with a cell pulverizer, and make The vanadium precursor is fully dissolved in the mixed solution to obtain solution A;

[0053] 2) After adding ethylene glycol, stir magnetically until the solution is uniform, the volume of ethylene glycol accounts for 3% of the volume of mixed solution A, add oxalic acid (H 2 C 2 o 4 ), the concentration of oxalic acid in the solution is 0.1mol / L, continue to stir until the reaction is sufficient, transfer it to a high-pressure reactor lined with polytetrafluoroethylene for hydrothermal reaction, the filling degree is 70%, and the hydrothermal reaction is carried out at 200 ° C 24h, natural cooling, obtain the reaction solution, pour out the supernatant in the reaction solution, obtain the reactant;

[0054] 3) Wash th...

Embodiment 2

[0060] 1) Configure a mixed solution of ethanol and deionized water with a volume ratio of 3:1, and add ammonium metavanadate, and the concentration of ammonium metavanadate in the solution is 0.025mol / L; crush the mixed solution with a cell pulverizer to make The vanadium precursor is fully dissolved in the mixed solution to obtain solution A;

[0061] 2) After adding ethylene glycol, stir magnetically until the solution is uniform, the volume of ethylene glycol accounts for 5% of the volume of the mixed solution A, add oxalic acid (H 2 C 2 o 4 ), the concentration of oxalic acid in the solution is 0.064mol / L, continue to stir until the reaction is fully transferred to a high-pressure reactor lined with polytetrafluoroethylene for hydrothermal reaction, the filling degree is 60%, hydrothermal reaction at 190 ° C 26h, natural cooling to obtain the reaction solution, pouring out the supernatant in the reaction solution to obtain the reactant;

[0062] 3) Wash the reactant th...

Embodiment 3

[0067] 1) Configure a mixed solution of ethanol and deionized water with a volume ratio of 2:1, and add ammonium metavanadate, the concentration of ammonium metavanadate in the solution is 0.03mol / L; use a cell pulverizer to pulverize the mixed solution to make The vanadium precursor is fully dissolved in the mixed solution to obtain solution A;

[0068] 2) After adding ethylene glycol, stir magnetically until the solution is uniform, the volume of ethylene glycol accounts for 10% of the volume of the mixed solution A, add formic acid (H 2 CO 2 ), the concentration of formic acid in the solution is 0.07mol / L, continue to stir until the reaction is fully transferred to a high-pressure reactor lined with polytetrafluoroethylene for hydrothermal reaction, the filling degree is 50%, and the hydrothermal reaction is carried out at 185°C 22h, natural cooling to obtain the reaction solution, pouring out the supernatant in the reaction solution to obtain the reactant;

[0069] 3) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com