Fast wind dehydrator for hot pickled mustard tuber

A dehydrator, fast technology for applications, food preparation, food science and more

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

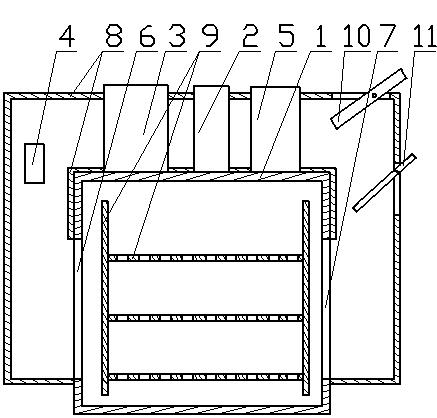

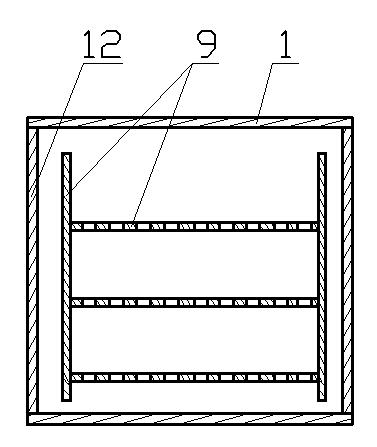

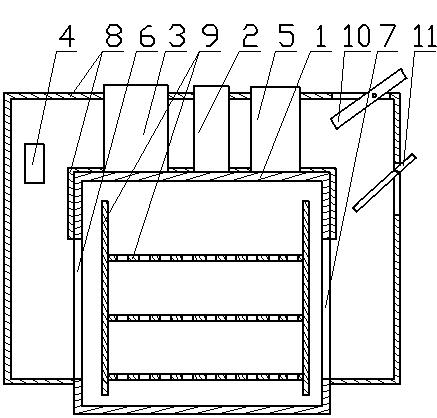

[0015] The mustard quick wind dehydrator of the present invention is mainly composed of a machine casing 1, a fan 2, a heating or heating device 3, a temperature sensing controller 4, a timing controller, a water filter 5, an air inlet 6, an air outlet 7, a pipeline 8, It is composed of movable ventilated material holding part 9, intake valve 10, hot air removal switch 11, door 12 and the like. There is an air inlet 6, an air outlet 7, and a door 12 on the machine shell 1; there is a movable ventilated material part 9 inside the machine shell 1; the air inlet 6 is connected to the heating or heating device 3 through the pipe 8, and then connected The fan 2 is connected to the water filter 5 through the pipeline 8, and then connected to the air outlet 7 through the pipeline 8; There is a hot air exhaust switch 11; the temperature sensing controller 4 is installed in the machine casing 1 or in the pipeline, and its line is connected to the heating or heating device 3; the timing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com