Continuous crystalizer

A technology of crystallizer and connecting parts, applied in the field of continuous crystallizer, can solve the problems of long time, uneven product particles, slow crystallization, etc., to achieve steady-state operation, production efficiency and product quality and particle size control improvement, strengthening The effect of mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

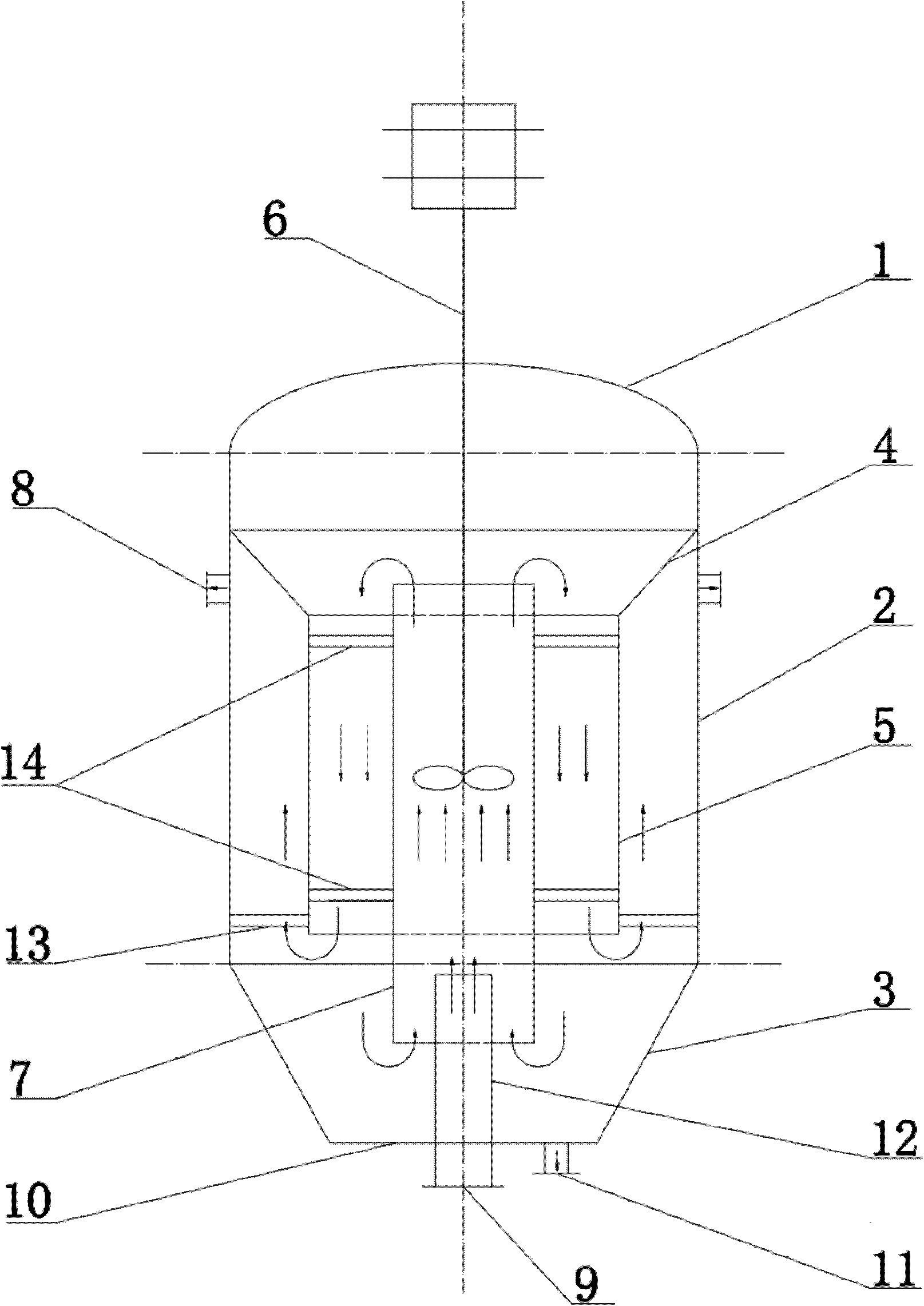

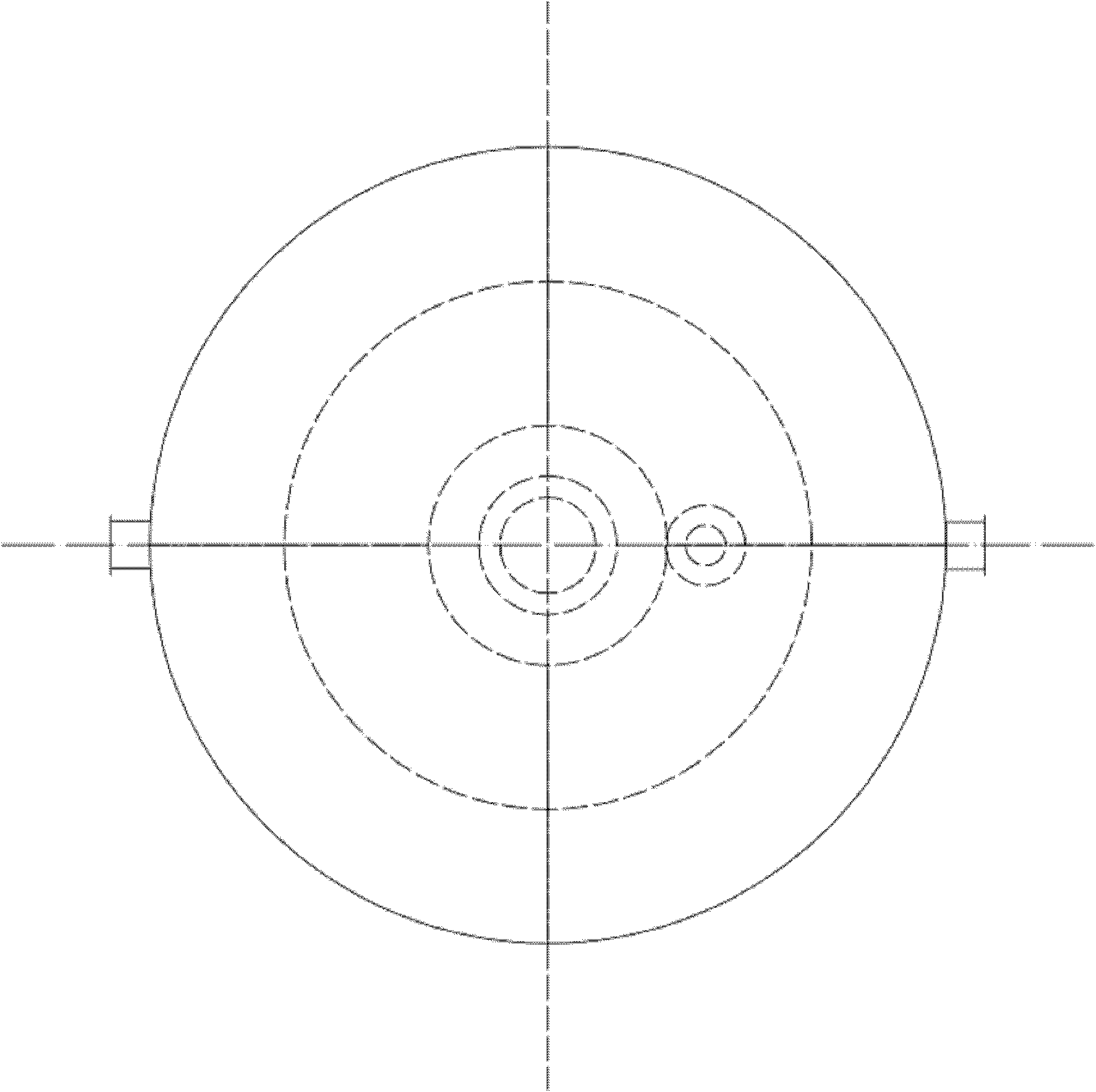

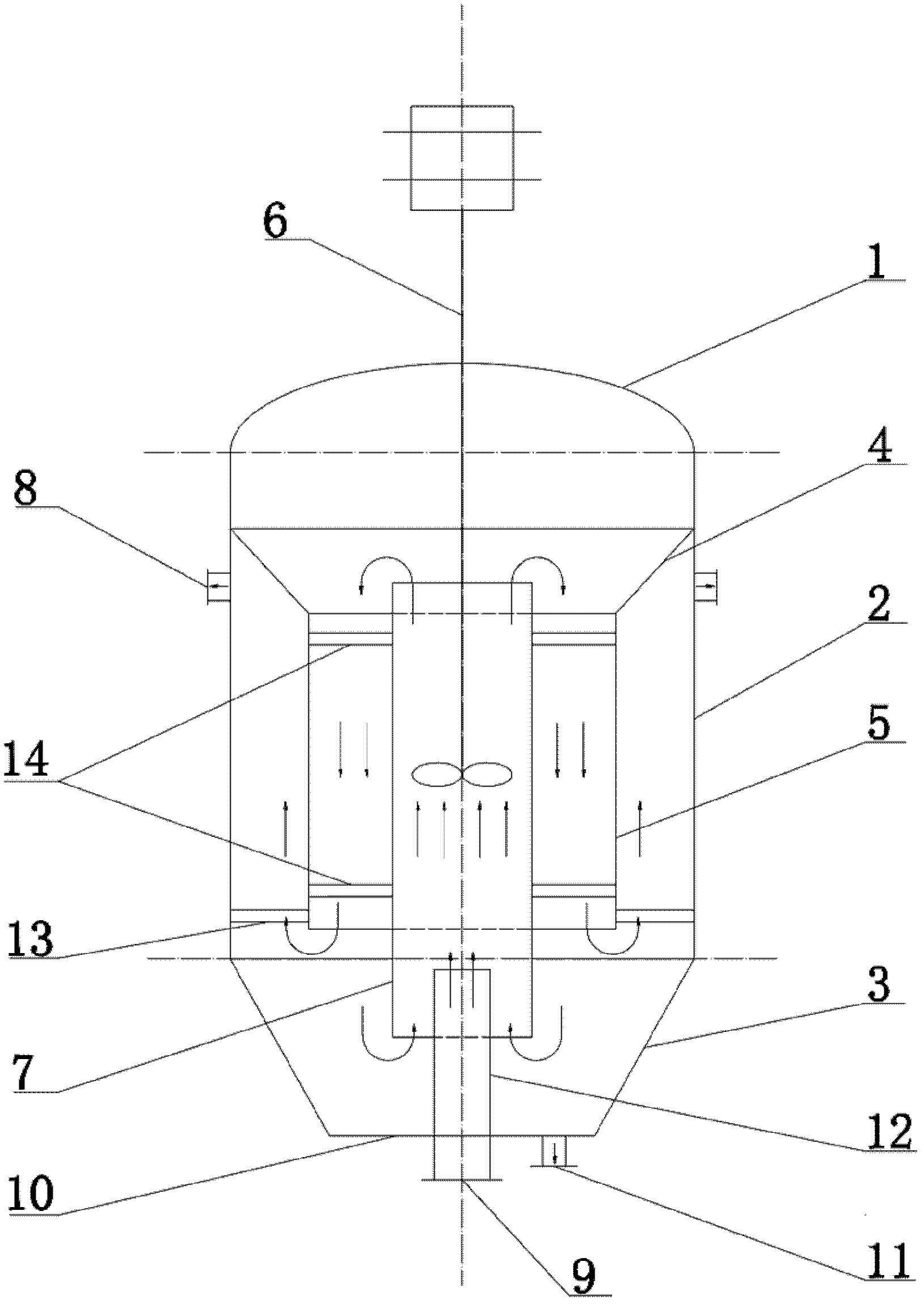

[0017] see figure 1 and figure 2 , figure 1 It is the structural representation of the continuous crystallizer of the present invention, figure 2 A top view of the crystallizer.

[0018] The continuous crystallizer of the present invention is used for the continuous crystallization of tetraacetylethylenediamine, comprising an upper head 1, an outer cylinder 2, a lower cone 3 and a lower head 10 connected in sequence; inside the outer cylinder 2, it is close to the upper head 1 The connecting part is provided with an inner cone 4; in the inside of the outer cylinder 2 and the lower cone 3, the lower edge of the inner cone 4 is connected with the inner cylinder 5; the inner cone 4 and the inner cylinder 5 are provided with a guide tube 7. There is a push-up agitator 6 inside the guide cylinder 7; two outer circulation material outlets 8 are provided below the connection between the outer cylinder 2 and the inner cone 4, and the outer circulation material inlet 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com