Improved annular jaw splice piece of hydraulic draw-bench

A technology of inserting and hydraulic pressure, which is applied in the field of inserting the ring jaw of the improved hydraulic puller, can solve the problems of increased product cost, increased steel pipe head forging, cutting process, and decreased steel pipe yield, so as to improve the cost rate , Prevent deformation of the steel pipe and increase the effect of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

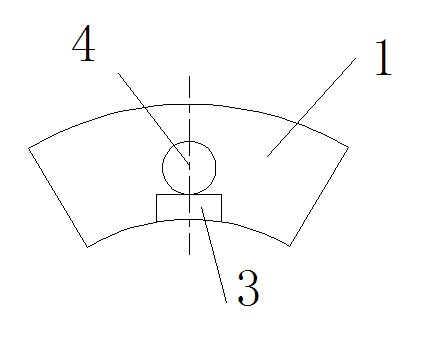

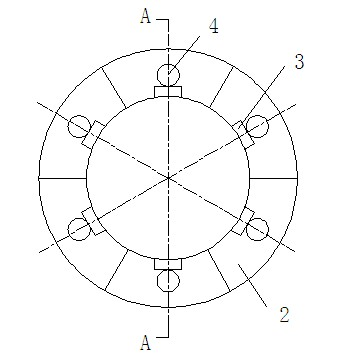

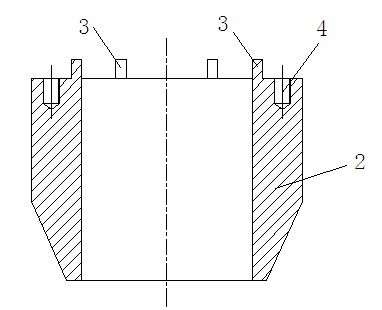

[0015] Such as figure 1 , 2 1. An improved annular jaw insert of a hydraulic puller shown in 3, the insert is composed of two or three fan rings 1, and the fan ring 1 is a matrix with a cylinder at the top and a cone at the bottom with a circular hole in the middle 2, the center of the top surface of each fan ring 1 is provided with square bumps 3 distributed in the same circular track along the inner circumference, and a threaded hole 4 is arranged concentrically on the outside of the square bumps. The square bumps 3 Matched with the threaded hole 4 and the jaw of the hydraulic puller, the hollow base 2 is divided into 2-6 pieces. When the base is divided into 2 pieces, the cut part of each semicircular base 2 is a fan ring 1, forming the 2 of the insert -Three fan rings 1 are fitted on the jaws of the hydraulic drawing machine at intervals of the same circular track, and the base body 1 is 45 steel with surface carburizing treatment.

[0016] When making this improved hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com