Weld line pressure plate

A pressing plate and welding wire technology, applied in the direction of welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of easy deformation of PCB board, unsatisfactory welding effect, contact with the bottom surface of the pressing plate, etc., so that it is not easy to release and avoid bad welding wire , the effect of gathering and heating up quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

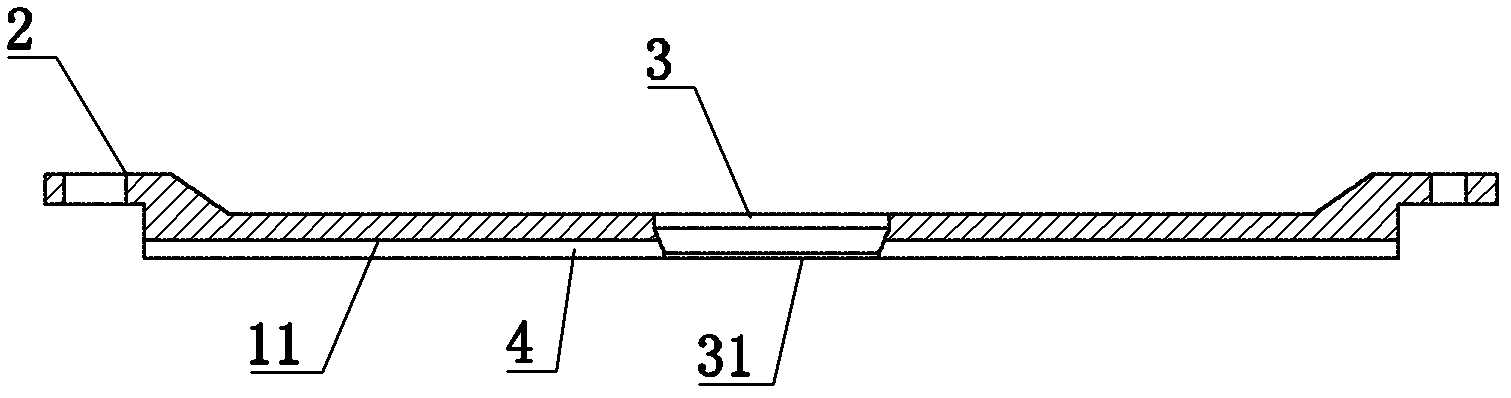

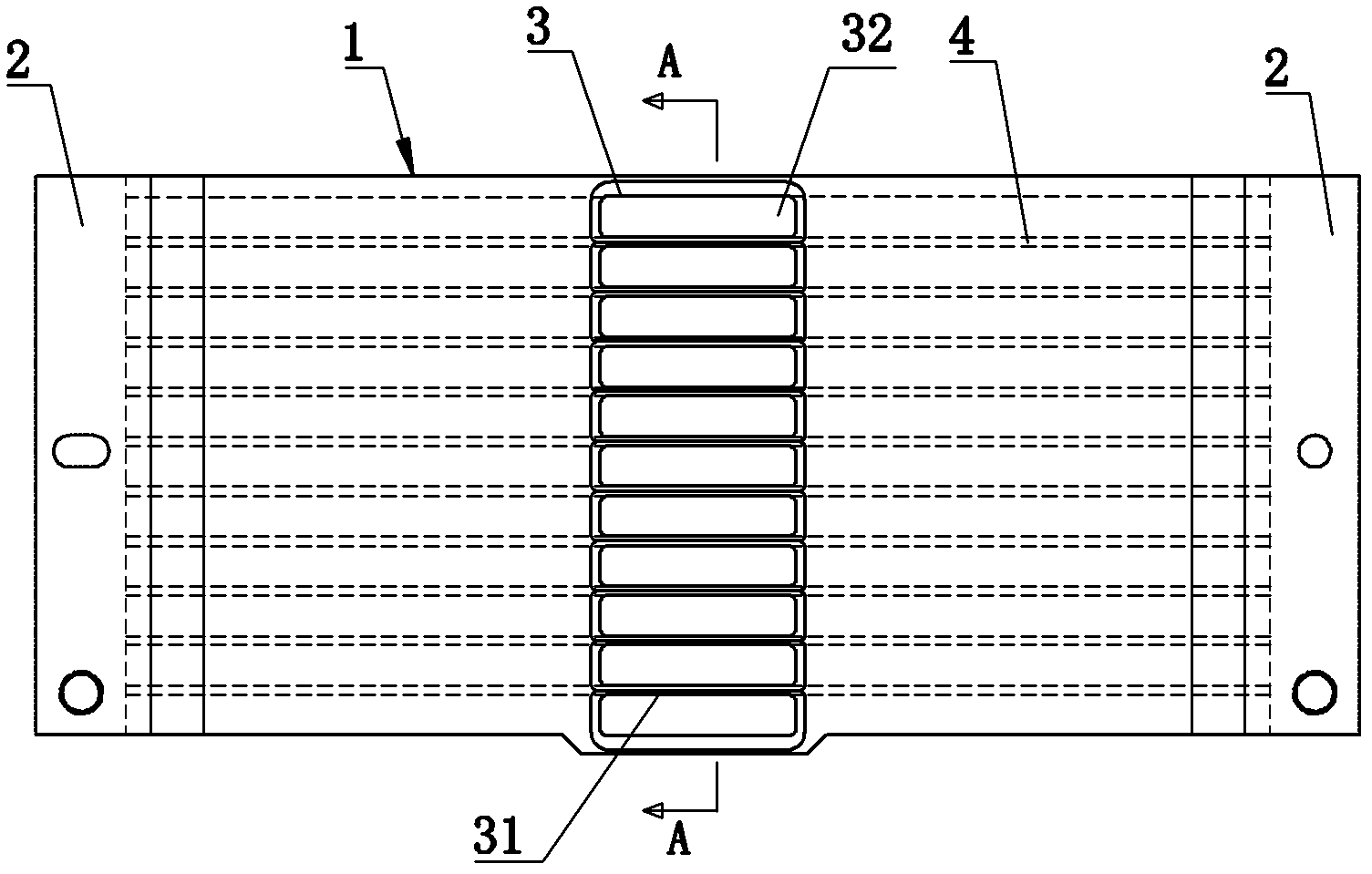

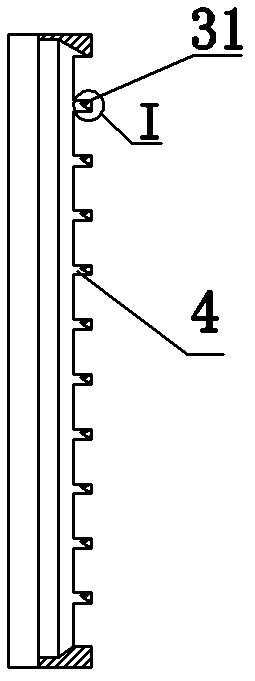

[0015] Such as figure 1 , figure 2 and image 3 Commonly shown, the welding wire pressing plate includes a pressing plate body 1, the bottom of the pressing plate body 1 is a pressing material surface 11, and the two sides of the pressing plate body 1 are respectively provided with installation parts 2 for connecting with the machine. Wire window 3, the welding wire window 3 is provided with several slitting ribs 31 arranged in parallel, and the slitting ribs 31 separate the welding wire window 3 into several welding areas 32, and the slitting ribs 31 are along the surface of the binder surface 11 toward Both sides extend and form ribs 4 protruding from the binder surface 11 , and two adjacent ribs 4 and the binder surface 11 jointly enclose an accommodating area.

[0016] Since there are several undivided small PCB boards neatly arranged on the overall PCB board, there are gaps between these small PCB boards. In the gaps between these undivided small PCB boards, the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com