Driving mechanism of bridge board rib assembling machine

A driving mechanism and assembly machine technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems affecting the assembly accuracy, undulation, twisting, and vibration of bridge slab ribs, and achieve simple structure, high degree of automation, and positioning. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

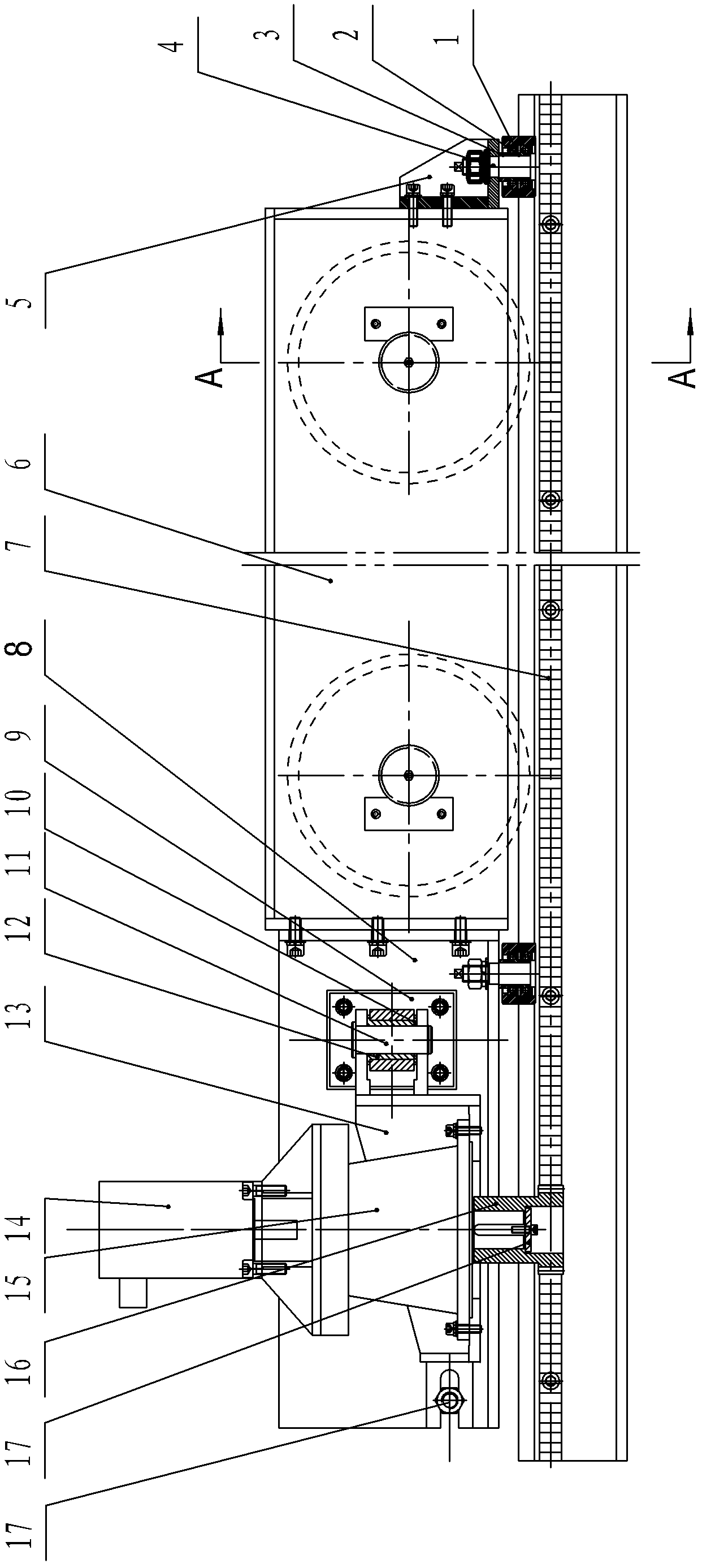

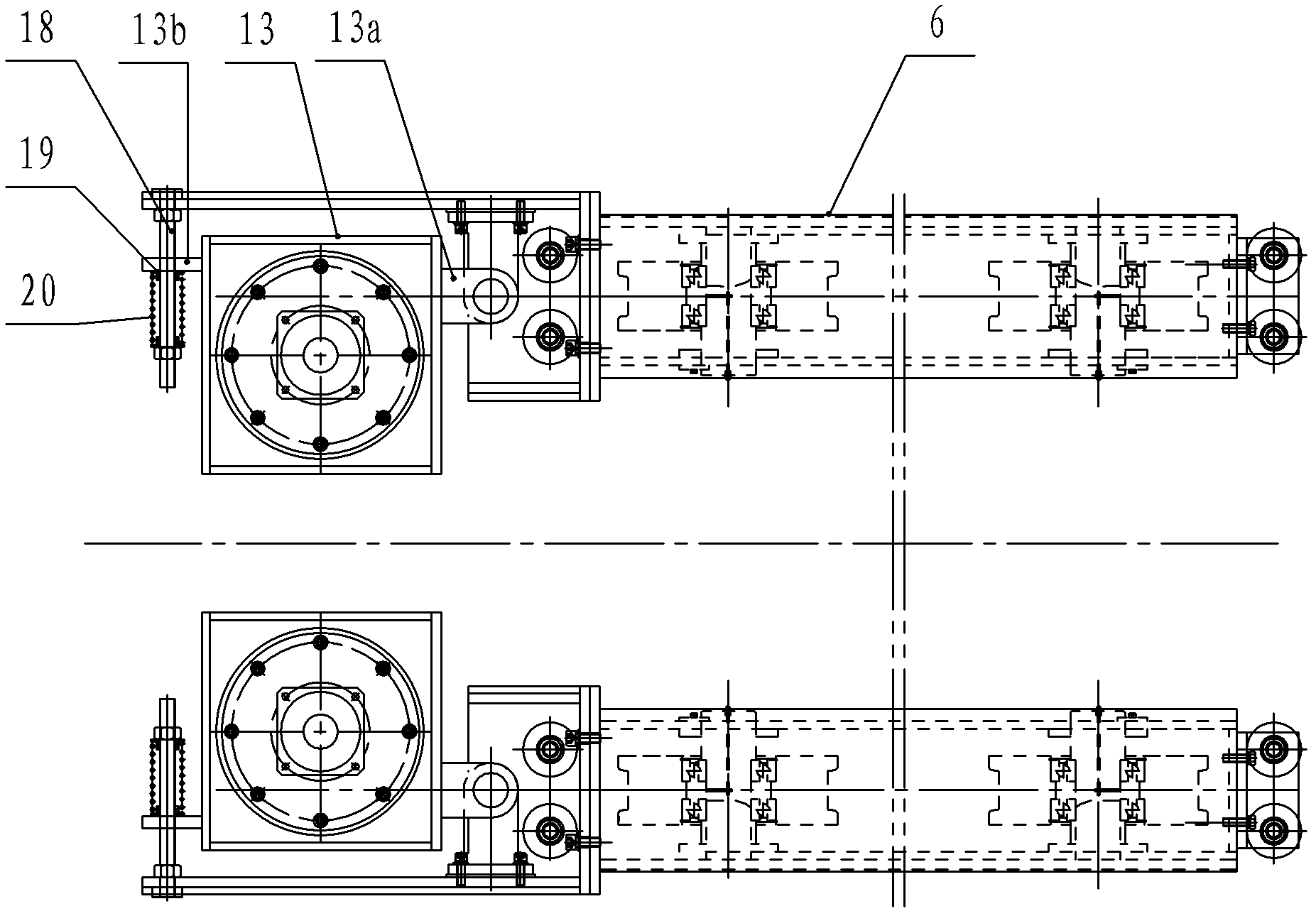

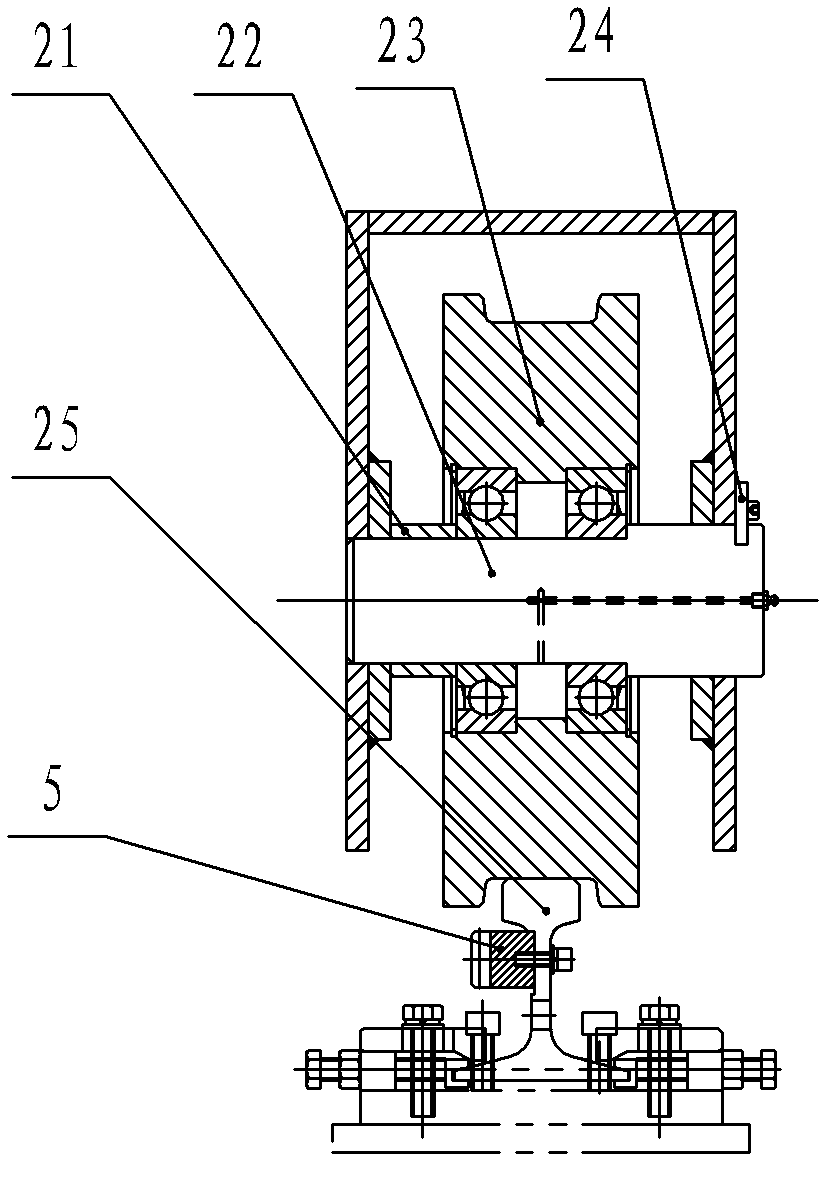

[0015] Such as Figure 1~Figure 3 As shown, the driving mechanism of the bridge slab rib assembly machine of the present invention is installed on the ground beam 6, and the ground beam 6 is supported on the guide rail 25 through the traveling wheels 23, and the traveling wheels 23 are supported and installed on the ground through the shaft 22 and the bearing assembly. In the beam 6, the end of the shaft 22 is clamped with a baffle plate 24 to prevent it from coming out, and the baffle plate 24 is fixed on the ground beam 6 with screws, and one side of the bearing assembly passes through the limit shoulder on the shaft 22. Blocked, the other side of the bearing assembly relies on the block sleeve 21 to withstand, so that the road wheel 23 will not shake. The rack 7 is fixed on the side of the guide rail 25 by screws, the stand 8 is fixed on the ground beam 6 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com