Back-bolt type drilling machine and method for machining back-bolt hole by using same

A drilling machine and back bolt technology, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of irregular shape of the 6'' steps, shortened effective connection length, difficulty in conforming to engineering construction, etc., to achieve crushing The effect of small strength, precise size and high processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] refer to Figure 7 , The back bolt type drilling machine includes a frame 1 at the bottom, an electric control box 2, a stone plate fastening device 3 (for pressing the stone plate on the workbench 4, this embodiment is a cylinder), installed on the machine The workbench 4 on the frame 1 and the crossbeam 5, the drilling device and two drilling devices 7 installed on the crossbeam 5. The electric control box 2 is arranged on the frame 1, and it adopts a PLC control system to automatically feed, retract, drill, and drill holes. It is easy to operate, high in machining accuracy, improves production efficiency, and then improves the economic benefits of the enterprise.

[0039] Also refer to Figure 11 and Figure 12 , the workbench 4 includes a frame 41 and a panel 42 with a mesh. The panel 42 is installed on the upper end of the frame 41. It is composed of a bottom plastic plate and a rubber plate on the surface. The frame 41 and the panel 42 can effectively support th...

Embodiment 2

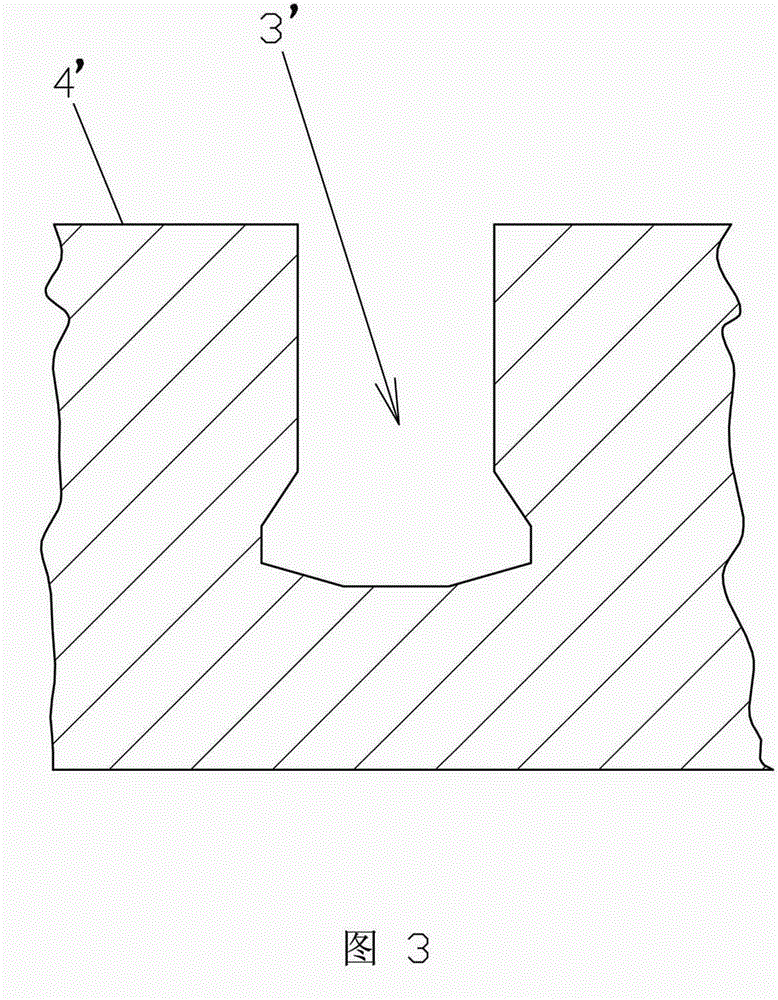

[0044] refer to Figure 15 , 16 and 17, the structure of this embodiment is basically the same as that of the above-mentioned embodiment 1 and the drilling method is exactly the same, the main difference is that the drill bit 72' of this embodiment has an upper cutter head 721' and a lower cutter head 722', and the lower cutter head 722 'The shape is the same as that of Embodiment 1, and the upper bit 721' is in the shape of a flat cylinder. This kind of drill bit 72' can process the back bolt hole 9' with a stepped surface 91', and the processed stepped surface 91' is relatively flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com