Chinese hemp stem-cracking mechanism

A technology for shredding stems and hemp, which is applied to the field of hemp shredding mechanisms, can solve the problems of poor removal of the rod core of the common stem shredding mechanism, incomplete processing of the ordinary stem shredding machine, and many dead crumbs. Improve processing efficiency and quality of finished products, improve extrusion force and work efficiency, and improve the effect of crushing stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

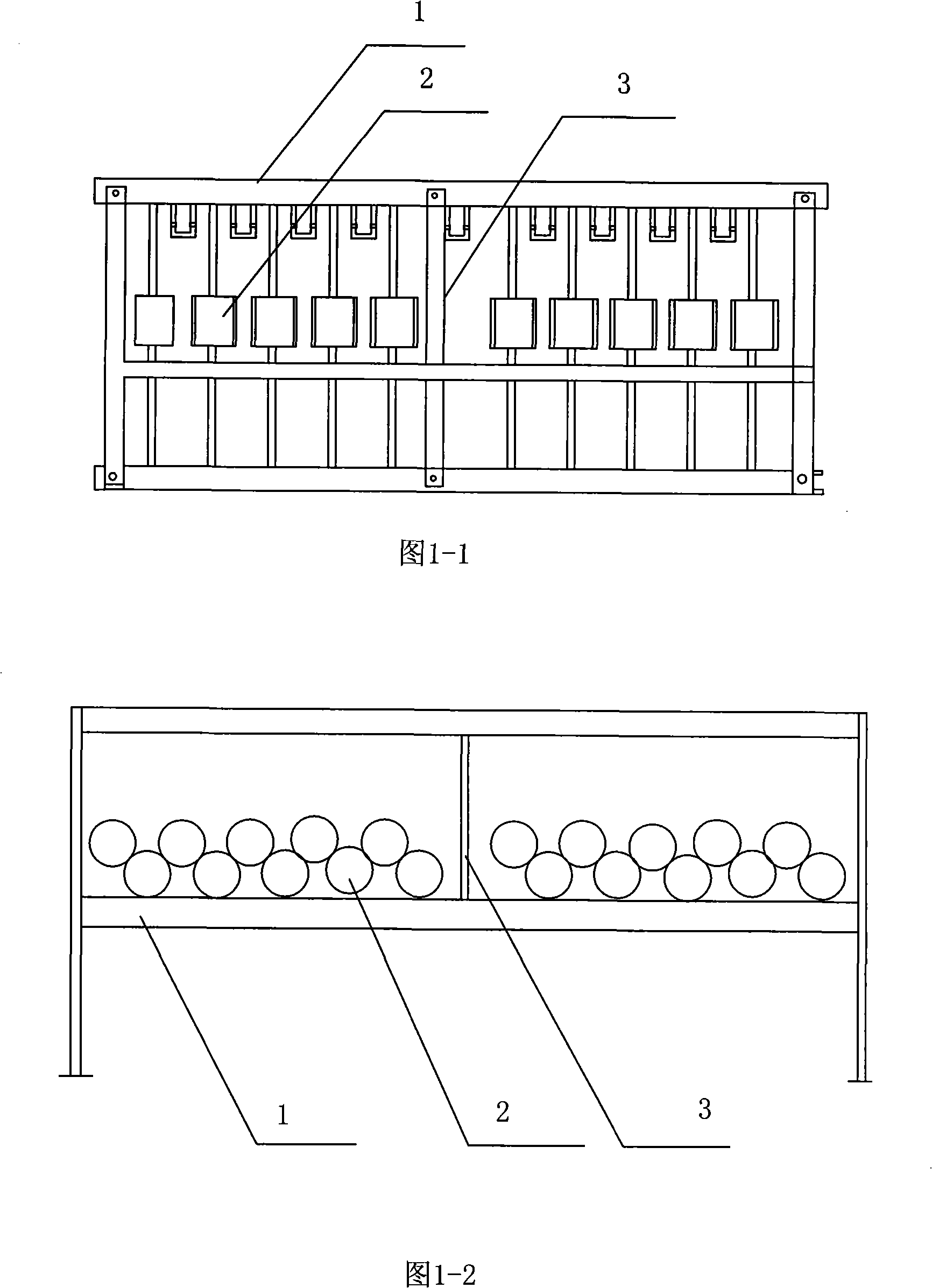

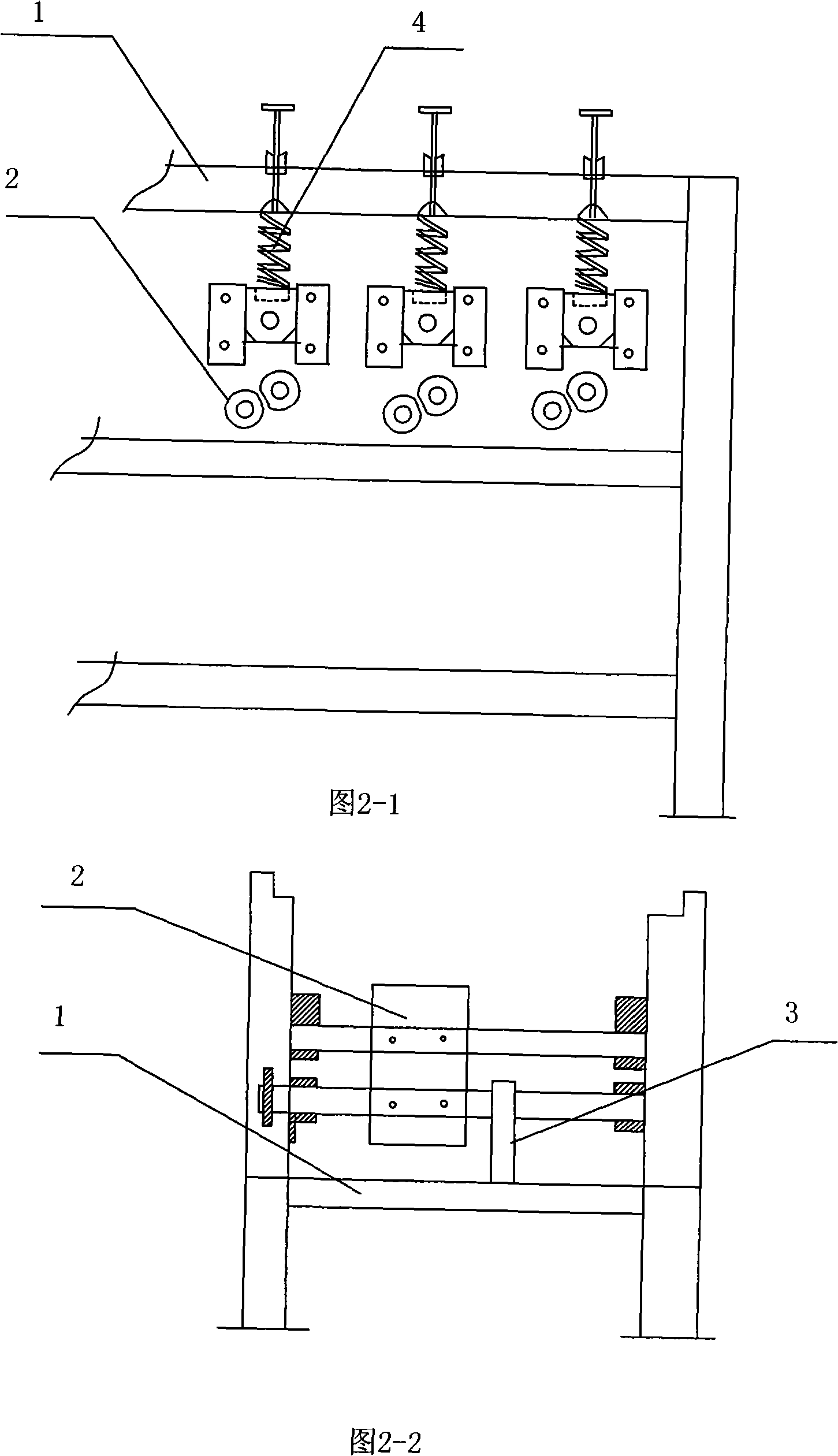

[0028] The present invention will be further described below in conjunction with the accompanying drawings. Picture 1-1 It is a top view of the structure schematic diagram of the present invention, Figure 1-2 It is the front view of the schematic diagram of the structure of the present invention. The purpose of the present invention is to manufacture a stem crushing mechanism for separating the hemp stems from the cortex. The coupling force between them facilitates the separation of the leather rods. The stem breaker of the present invention comprises parts such as frame, retaining pin, roller, compression spring, and operating process is as follows:

[0029] Under the action of external mechanical force, the dry stem and the rollers are rolled at an angle of 45°-75° and fed into the stem crushing mechanism, and then the tip of the hemp stem layer enters the first group of five pairs of rollers with 18 teeth at the front end. Under the extruding and bending of the five pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com