Reinfored bar rolling thread connector and connecting method

A threaded connector and threaded connection technology, applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problem of increasing the unevenness of force on each thread and stress concentration, affecting the external output of building construction technology, Issues such as restrictions on the use of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

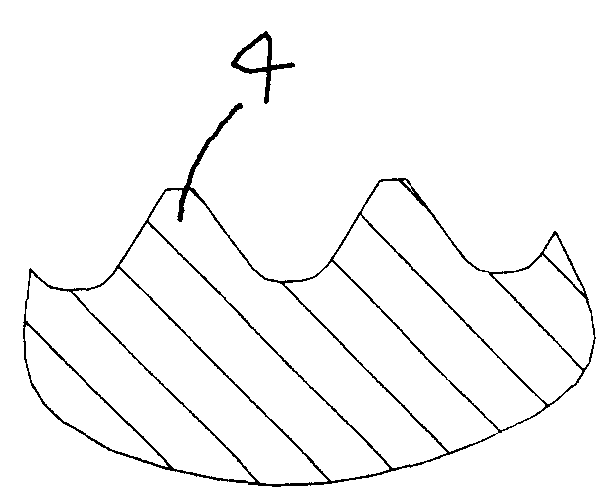

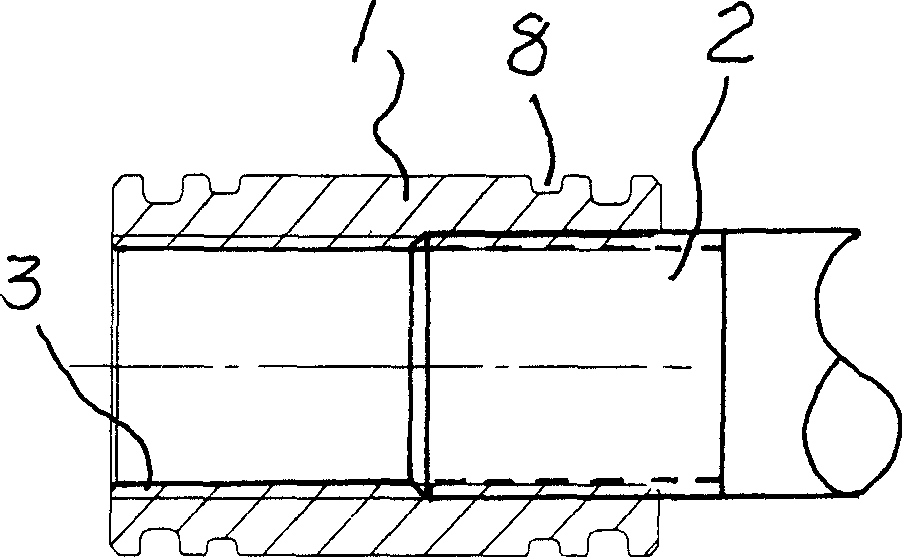

[0008] Embodiment 1: With reference to Fig. 1, Fig. 2. For the connecting sleeve and the steel bar, the present invention only designs the profile angle of the (internal) thread of the connecting sleeve and the (external) thread of the steel bar to be 75°, and the tooth height is designed to be 0.38~0.43 times of the pitch, preferably the tooth height is 0.41 times the pitch. In practice, the purpose of the invention can be achieved as long as one or both ends of the connecting sleeve are screwed with steel bars.

Embodiment 2

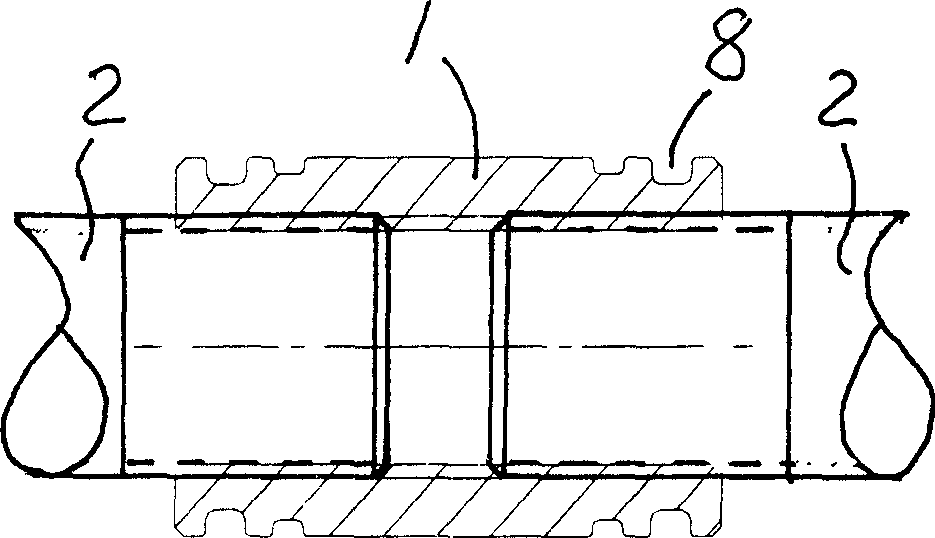

[0009] Embodiment 2: Refer to Fig. 3 and Fig. 4 . In this embodiment, on the basis of Embodiment 1, the connecting sleeve is designed as two sections of (internal) threads with relative left and right hand directions, and the left and right (inner) threads are respectively screwed with steel bars matching the hand directions. The outer diameters of the steel bars at both ends of the connecting sleeve can be the same or different.

Embodiment 3

[0010] Embodiment 3: Refer to FIG. 5 . In this embodiment, the bottom diameters of the two sections (internal) threads in the left and right directions of the connecting sleeve are different, and a telescopic sleeve with internal threads and external threads at both ends is used to screw the external threads of the telescopic sleeve on On the (internal) thread matched with the connecting sleeve, the internal thread of the telescopic sleeve is screwed on the (external) thread of the steel bar, and the length after the steel bar is connected can be adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com