Release film with high anti-static property and method for manufacturing the same

A manufacturing method and release film technology, applied in the direction of static electricity, chemical instruments and methods, electrical components, etc., can solve the problem of poor antistatic performance, unsuitability, release force and residual adhesive rate and other release characteristics degradation and other problems, to achieve the effect of good release characteristics and excellent anti-static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

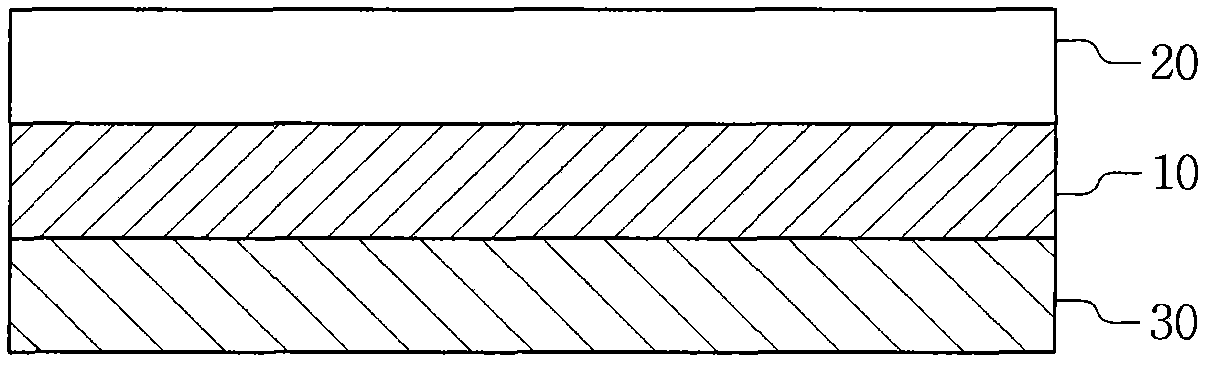

[0051] A silicone release layer is formed on one side of the polyethylene terephthalate (PET) film, and an antistatic layer is formed on the other side, such as figure 1 As shown, a release film test piece with a three-layer structure was produced. The weight proportion of above-mentioned organosilicon release layer accounts for 10 parts according to the weight of organopolysiloxane, the weight of hydrogen-containing organopolysiloxane accounts for 0.01 part, the weight of platinum chelate accounts for 0.1 part, and solvent (toluene ) constitutes 100 parts by weight.

[0052] And, the weight proportion of the antistatic mixture of above-mentioned antistatic layer is, as the weight of the acryloyl chloride resin of adhesive agent 15 parts, the weight of polyethylenedioxythiophene (PEDOT) as antistatic agent 10 parts, ethanol (common 30 parts by weight of alcohol) and 45 parts by weight of water, the antistatic mixture is coated on a polyethylene terephthalate (PET) film to for...

Embodiment 2

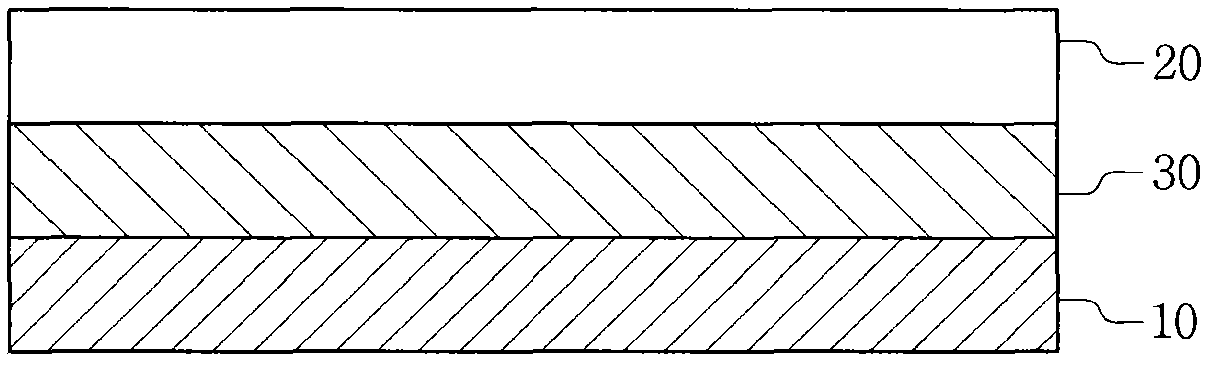

[0054] Same as above-mentioned embodiment 1, antistatic layer is placed between polyethylene terephthalate (PET) film and organic silicon release layer, has figure 2 3-layer construction shown. Specifically, the same antistatic mixture as in Example 1 was coated on a polyethylene terephthalate (PET) film to form an antistatic layer, and then a silicone release layer was formed on the antistatic layer.

Embodiment 3

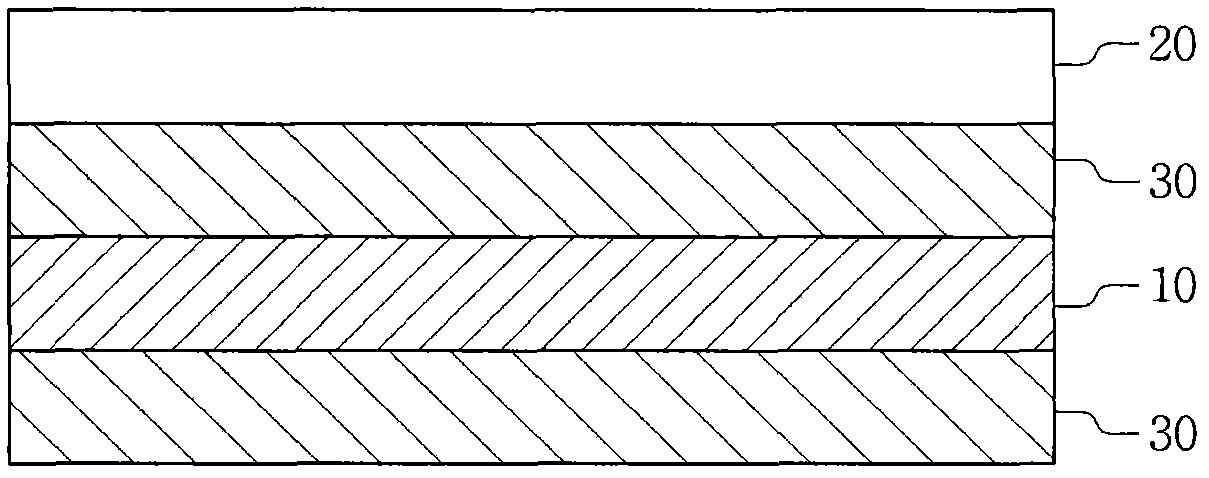

[0056] Compared with above-mentioned embodiment 1, antistatic layer is formed on both sides of polyethylene terephthalate (PET) film, as image 3 As shown, it has a 4-layer structure. Specifically, an antistatic compound is coated on both sides of a polyethylene terephthalate (PET) film to form a two-layer antistatic layer, and then a silicone release layer is formed on one side. At this time, the same antistatic mixture as in the above-mentioned examples was used for the two antistatic layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com