Antistatic halogen-free flame retardation polypropylene sheet and making method thereof

A flame-retardant polypropylene and anti-static technology, applied in the field of anti-static halogen-free flame-retardant polypropylene sheet and its preparation, can solve the problems of the decline of physical properties of the sheet, the falling of burning objects, and the limitation of use, and achieve flame retardant High performance, good anti-static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

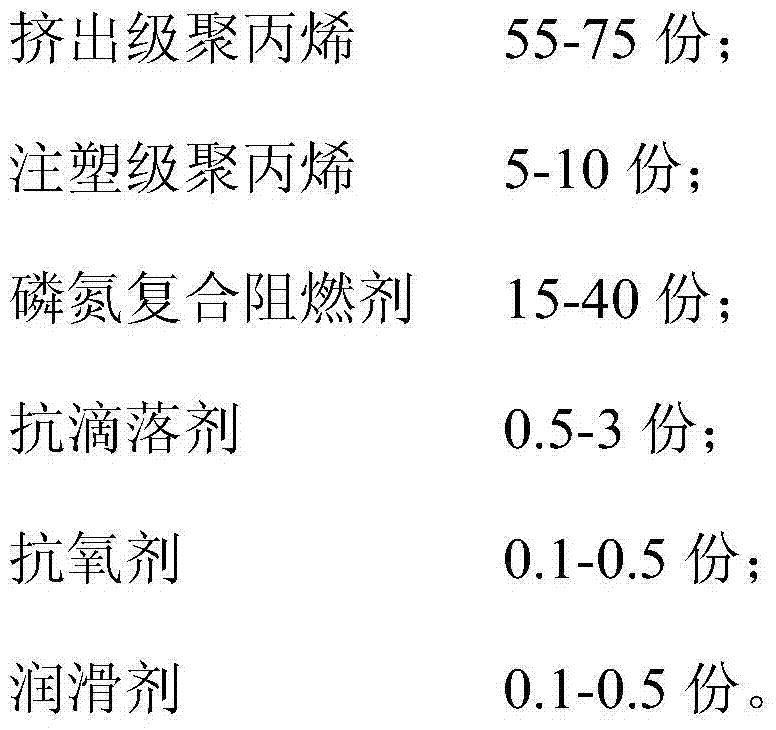

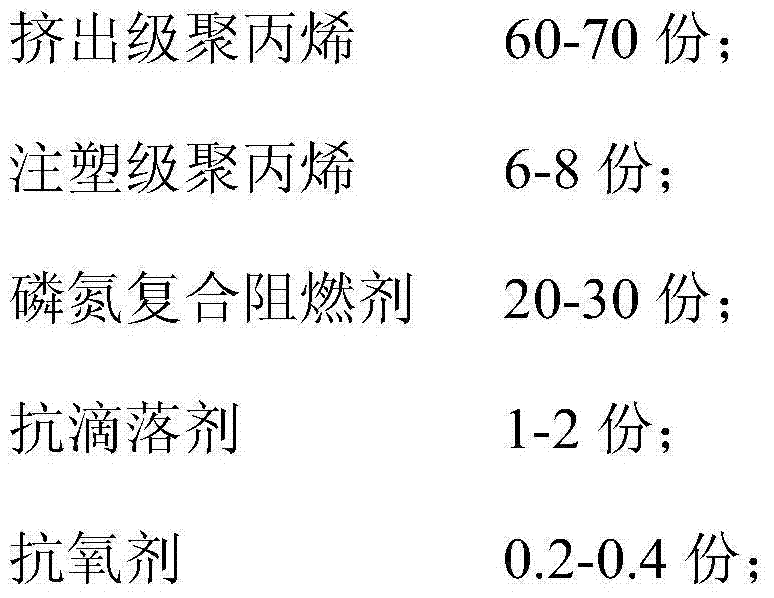

Method used

Image

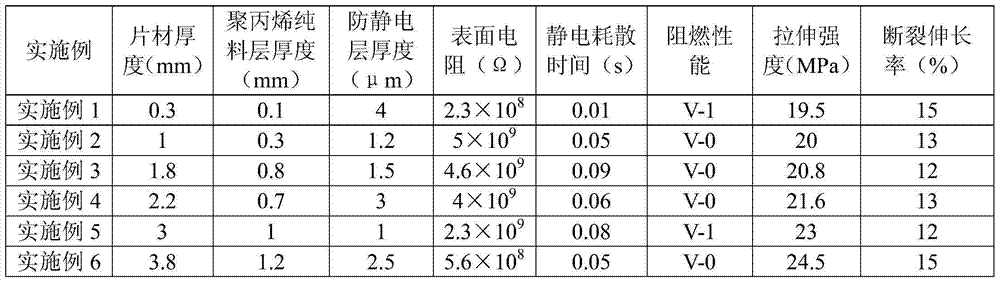

Examples

Embodiment 1

[0032] Weigh 60kg extrusion grade polypropylene, 7kg injection molding grade polypropylene, 23kg phosphorus nitrogen composite flame retardant, 1.5kg polytetrafluoroethylene dripping agent, 0.2kg antioxidant 1010, 0.2kg zinc stearate lubricant, by The twin-screw extruder extruded and granulated at 195°C to obtain halogen-free flame-retardant polypropylene pellets; put the pure polypropylene pellets into the main screw hopper of the three-layer co-extrusion sheet equipment, and the halogen-free flame-retardant polypropylene pellets Put it into the auxiliary screw hopper, melt and plasticize at 195°C respectively, and calender and extrude through the three-layer co-extruded sheet equipment. Propylene: Polythiophene is used as a conductive polymer, and isopropanol is used as a solvent to prepare a conductive polymer solution, and the conductive polymer is coated on the outside of the above-mentioned flame-retardant layer, polypropylene pure material layer, and flame-retardant laye...

Embodiment 2

[0035] Weigh 65kg of extrusion grade polypropylene, 8kg of injection molding grade polypropylene, 25kg of phosphorus nitrogen composite flame retardant, 2kg of polytetrafluoroethylene dripping agent, 0.3kg of antioxidant 1010, and 0.3kg of zinc stearate lubricant. The screw extruder is extruded and granulated at 190°C to obtain halogen-free flame-retardant polypropylene pellets; put the pure polypropylene pellets into the main screw hopper of the three-layer co-extrusion sheet equipment, and put the halogen-free flame-retardant polypropylene pellets Enter the auxiliary screw hopper, melt and plasticize separately at 190°C, calender and extrude through a three-layer co-extrusion sheet equipment, cool and trim after forming to obtain a flame-retardant layer, polypropylene pure material layer, flame-retardant layer, halogen-free flame-retardant polypropylene ; Polypyrrole is used as the conductive polymer, and ethanol / water (1:1 mass ratio) is used as the solvent to prepare the co...

Embodiment 3

[0037] Weigh 70kg of extrusion grade polypropylene, 5kg of injection molding grade polypropylene, 25kg of phosphorus nitrogen composite flame retardant, 1kg of polytetrafluoroethylene dripping agent, 0.2kg of antioxidant 1010, and 0.2kg of zinc stearate lubricant. The screw extruder is extruded and granulated at 190°C to obtain halogen-free flame-retardant polypropylene pellets; put the pure polypropylene pellets into the main screw hopper of the three-layer co-extrusion sheet equipment, and put the halogen-free flame-retardant polypropylene pellets Enter the auxiliary screw hopper, melt and plasticize separately at 190°C, calender and extrude through a three-layer co-extrusion sheet equipment, cool and trim after forming to obtain a flame-retardant layer, polypropylene pure material layer, flame-retardant layer, halogen-free flame-retardant polypropylene ; Polypyrrole is used as the conductive polymer, and ethanol / water (1:1 mass ratio) is used as the solvent to prepare the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com