Walking hydraulic control system and self-walking type engineering machinery utilizing same

A hydraulic control system, right-hand walking technology, applied in the direction of control devices, mechanical equipment, fluid pressure actuators, etc., can solve the problems of asynchronous drive of travel motors, uneven friction, aggravated wheels, etc., to improve speed synchronization, Avoid out-of-synchronization drive and improve the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

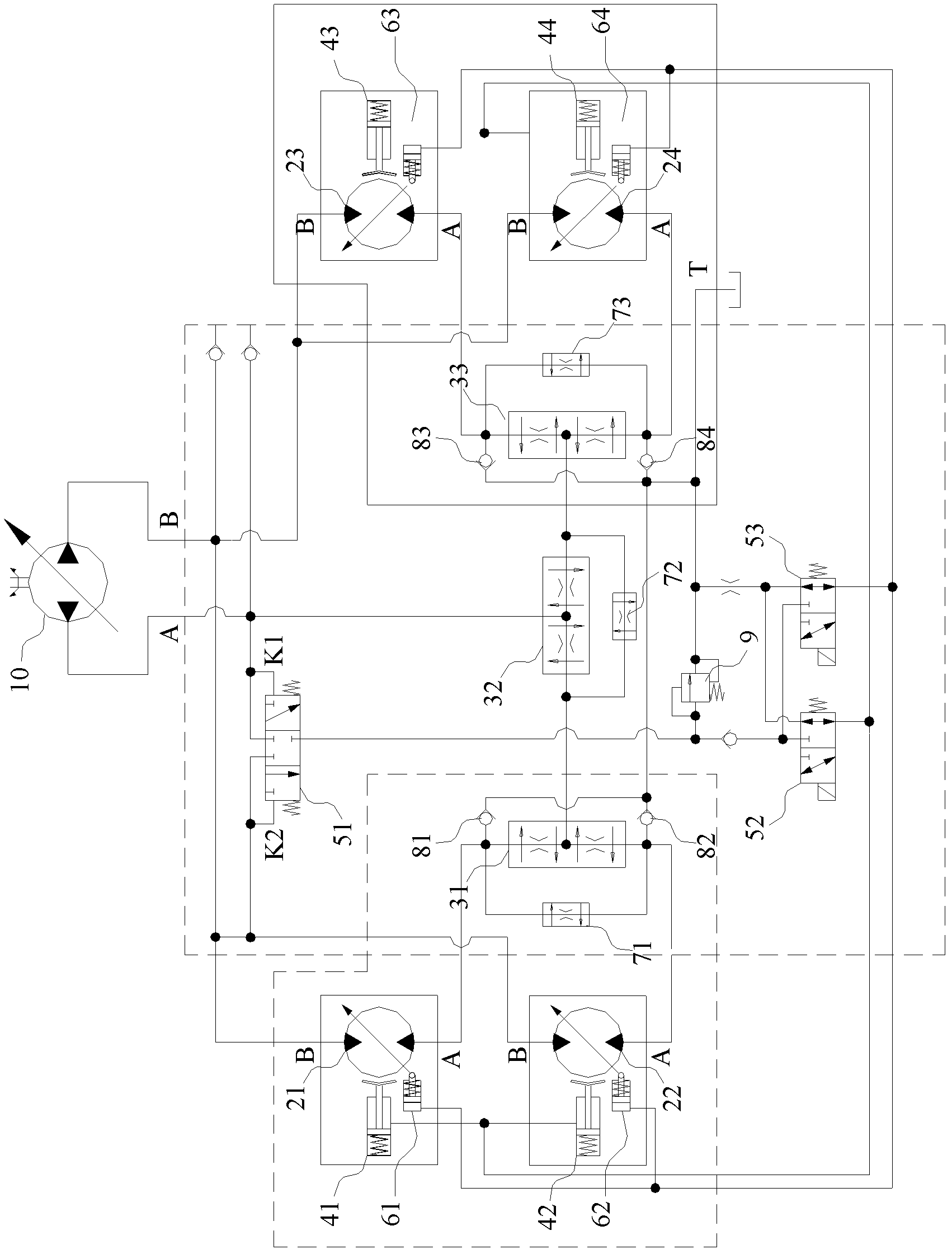

[0031] The core of the present invention is to provide a walking hydraulic control system, which can effectively control the speed synchronization of the traveling motors on both sides by changing the system configuration. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0032] Without loss of generality, this embodiment will be described in detail with the aerial work platform as the main body.

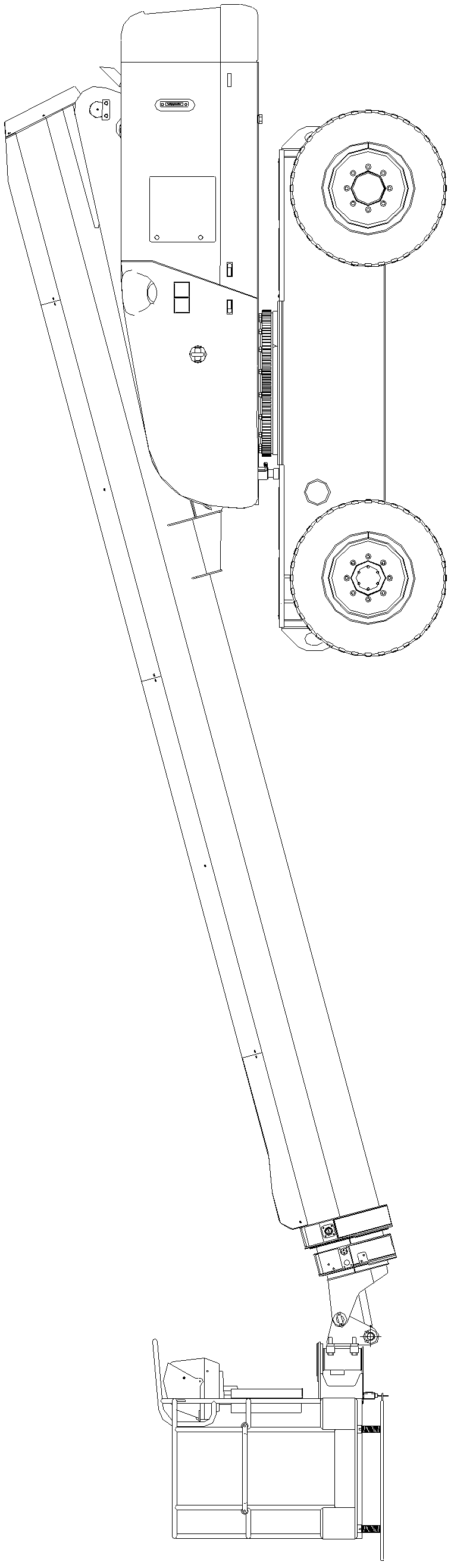

[0033] See figure 2 , which shows a schematic diagram of the overall structure of the aerial work platform vehicle.

[0034] As shown in the figure, the main functional parts of the aerial work platform vehicle, such as the various functional components on the vehicle and the walking chassis for getting off the vehicle, can be realized in the same way as the existing technology; Walking operations such as forward, backward or turning of the vehicle. It should be noted that those skilled in the art can implement the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com