Sealing mechanism for plane wing surfaces

A technology of surface sealing and sealing mechanism, which is applied in the directions of aircraft parts, aircraft control, transportation and packaging, etc. It can solve the problems of large step difference between the end of the sealing strip and the wing, damage to the theoretical shape of the airfoil, and poor sealing of the sealing strip. To achieve long service life, ensure the aerodynamic performance of the airfoil, and delay the separation of airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

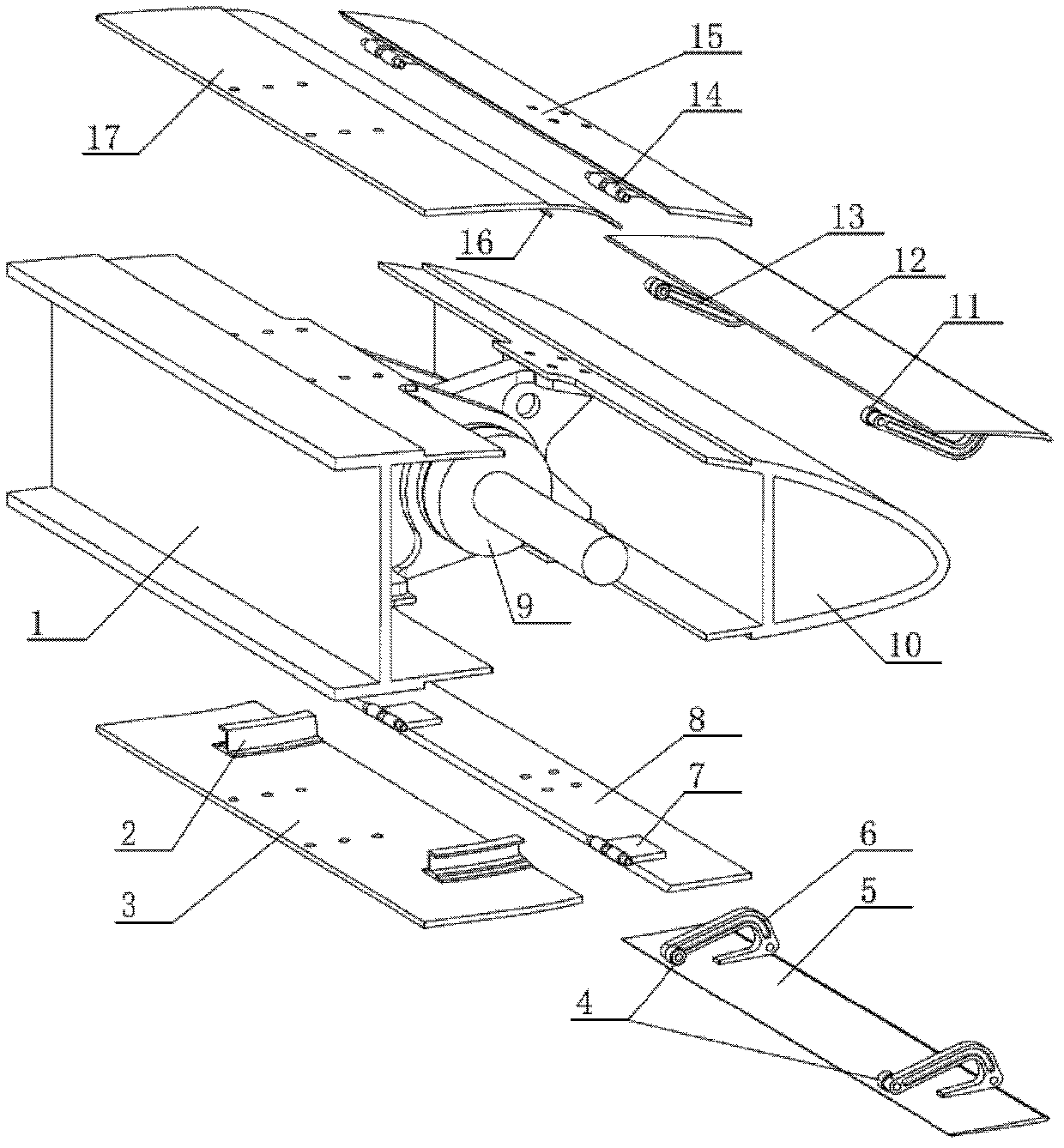

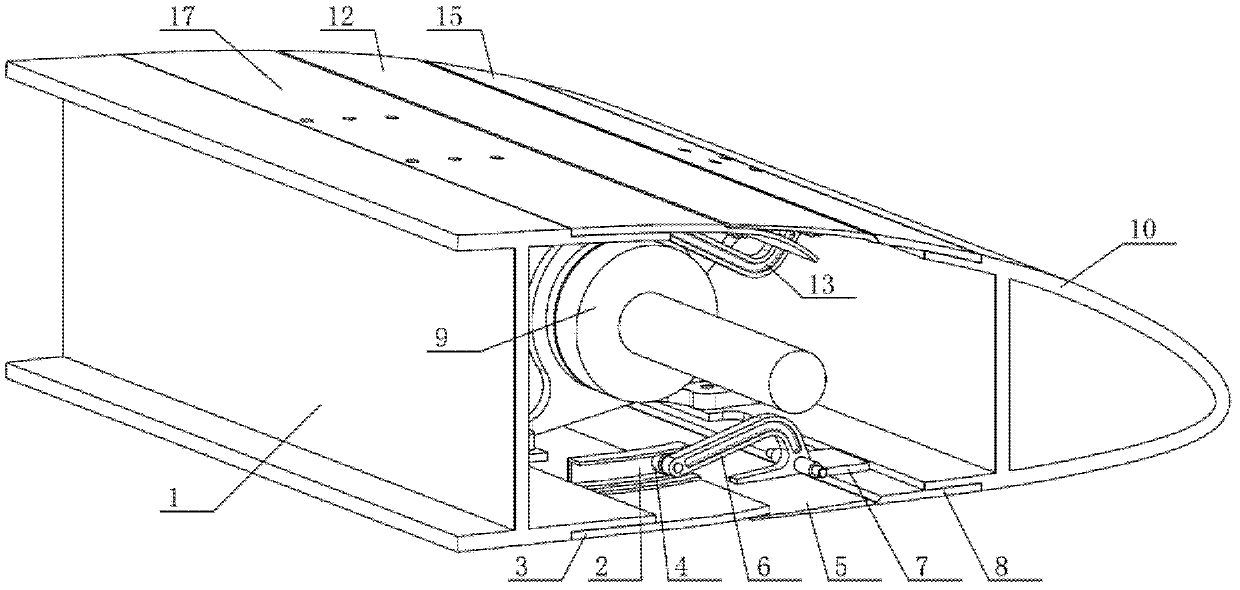

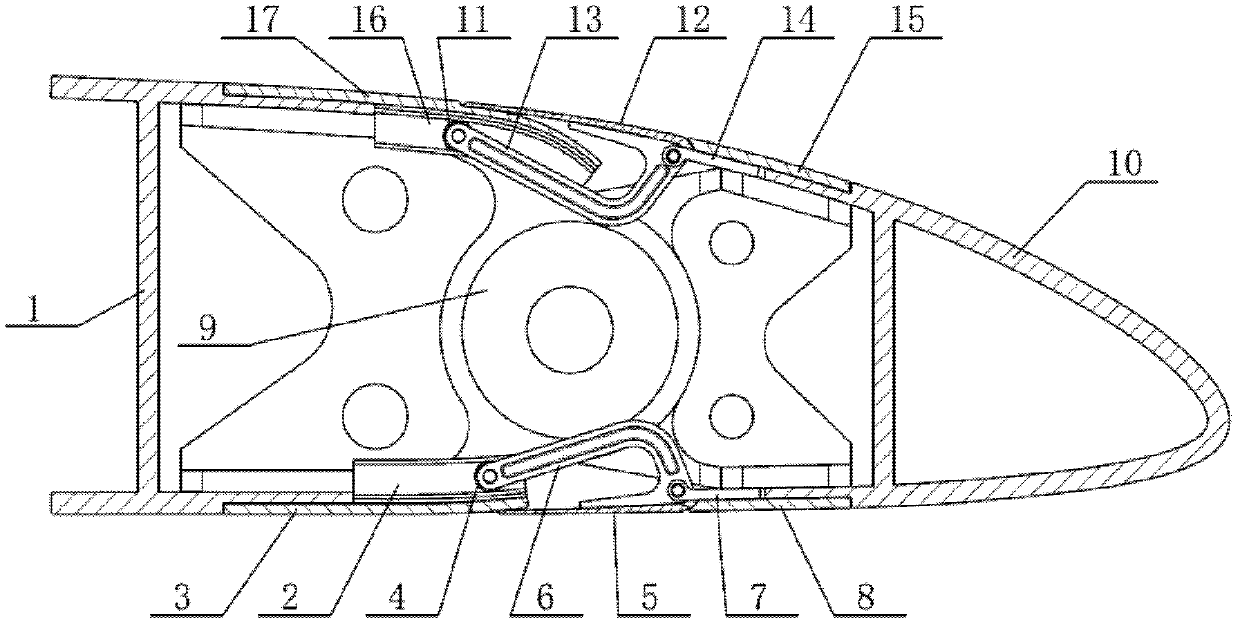

[0030]This embodiment is a sealing mechanism for the gap between the surface of the flap of the aircraft and the surface of the wing, including a sealing strip, a pulley, a slide rail, a hinge joint and a pulley support arm. Described sealing strip comprises sealing strip 15 in front of the upper wing, sealing strip 12 in the upper wing surface, sealing strip 17 behind the upper wing surface, sealing strip 8 in front of the lower wing surface, sealing strip 3 behind the lower wing surface and sealing strip in the lower wing surface 5. The slide rails include an upper airfoil slide rail 16 and a lower airfoil slide rail 2 . The pulleys include an upper airfoil pulley 11 and a lower airfoil pulley 4. The hinge joints adopt invisible hinge joints, including upper airfoil hinge joints 14 and lower airfoil hinge joints 7 . The pulley arm includes an upper airfoil pulley arm 13 and a lower airfoil pulley arm 6 . The sealing strip 15 in front of the upper wing, the rear sealing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com