Drying method for drum washing machine

A drum washing machine and a reference value technology, which is applied to the control device of the washing machine, washing device, textile and paper making, etc., can solve the problems of not being rationally used, and the drying effect cannot meet the needs of users, and achieve the effect of meeting the needs of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

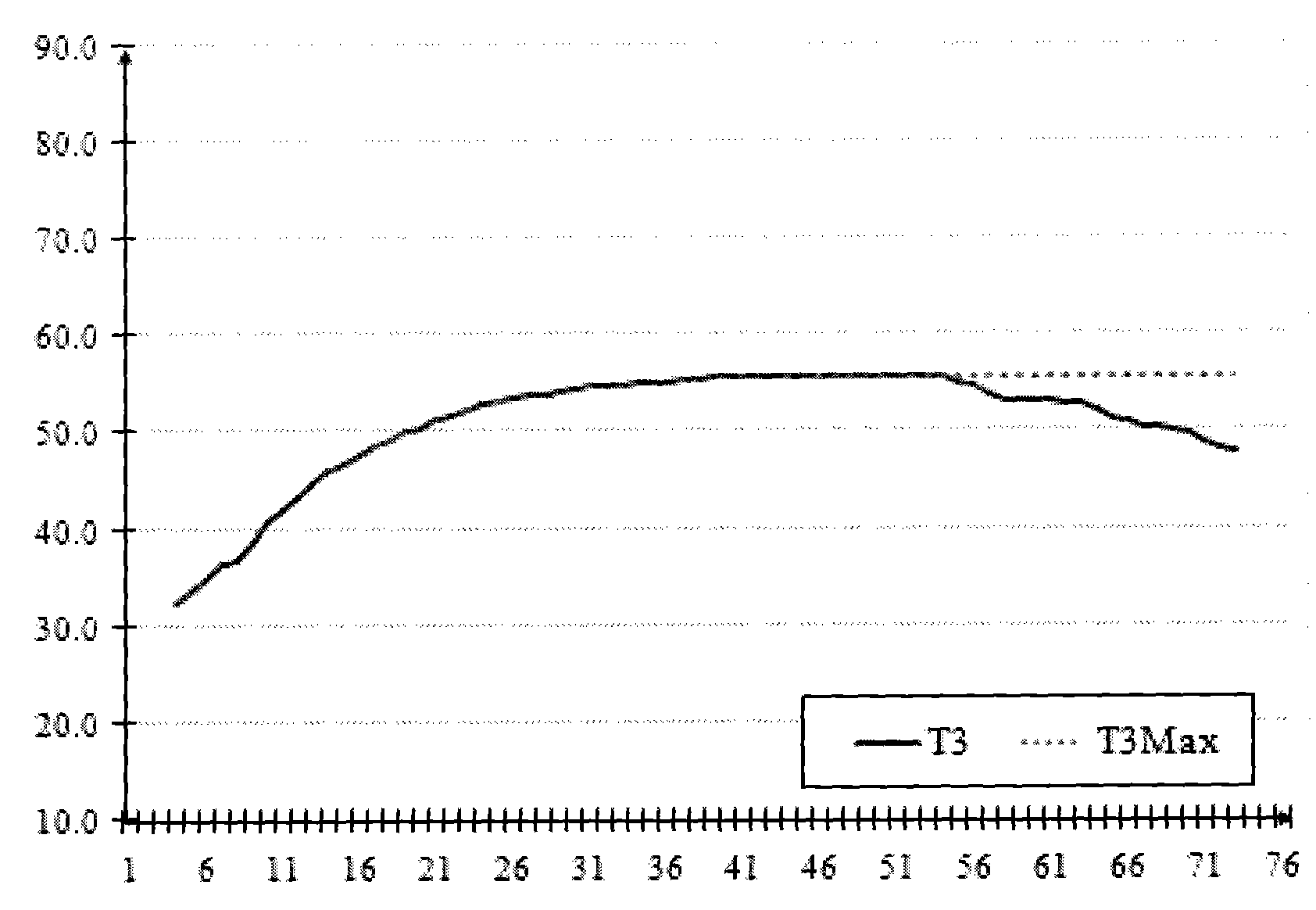

[0012] The drying method of drum washing machine is different in that it includes the following steps: step ①, collecting the feedback signal generated by the rotation of the motor, and judging the size of the load in the bucket by calculating and integrating the data of the feedback signal, that is, dividing it into large and medium , small three levels, each level corresponds to an independent reference value σ3i reference value. In step ②, during the drying process, the temperature of the temperature sensor at the condenser end is collected in real time, and when the difference between the real-time detected temperature value and the maximum limit temperature value is greater than the reference value, it is determined that the drying is over. Step ③, the control chip compares the difference between the T3 value and T3Max with the σ3i reference value after the set time, and calls the relevant variable function of the drying drive module. If the difference between the T3 value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com