Positive pressure deflating valve

A technology of air release valve and valve body, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., and can solve the problems that the opening of the air release valve cannot be controlled, the sensor of the mechanism is damaged, and the pressure difference becomes large. Easy to control, protect normal use, turn on the effect of controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

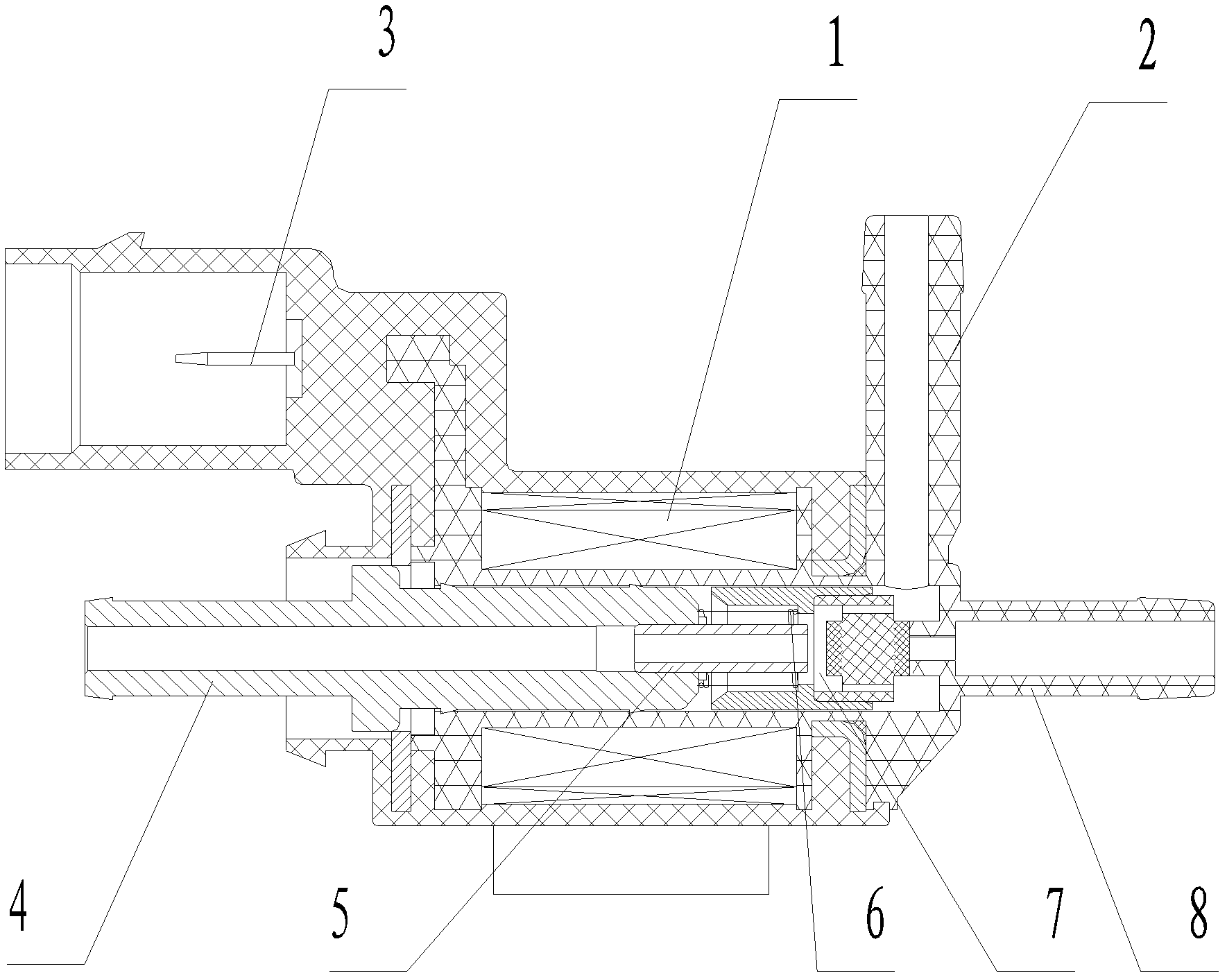

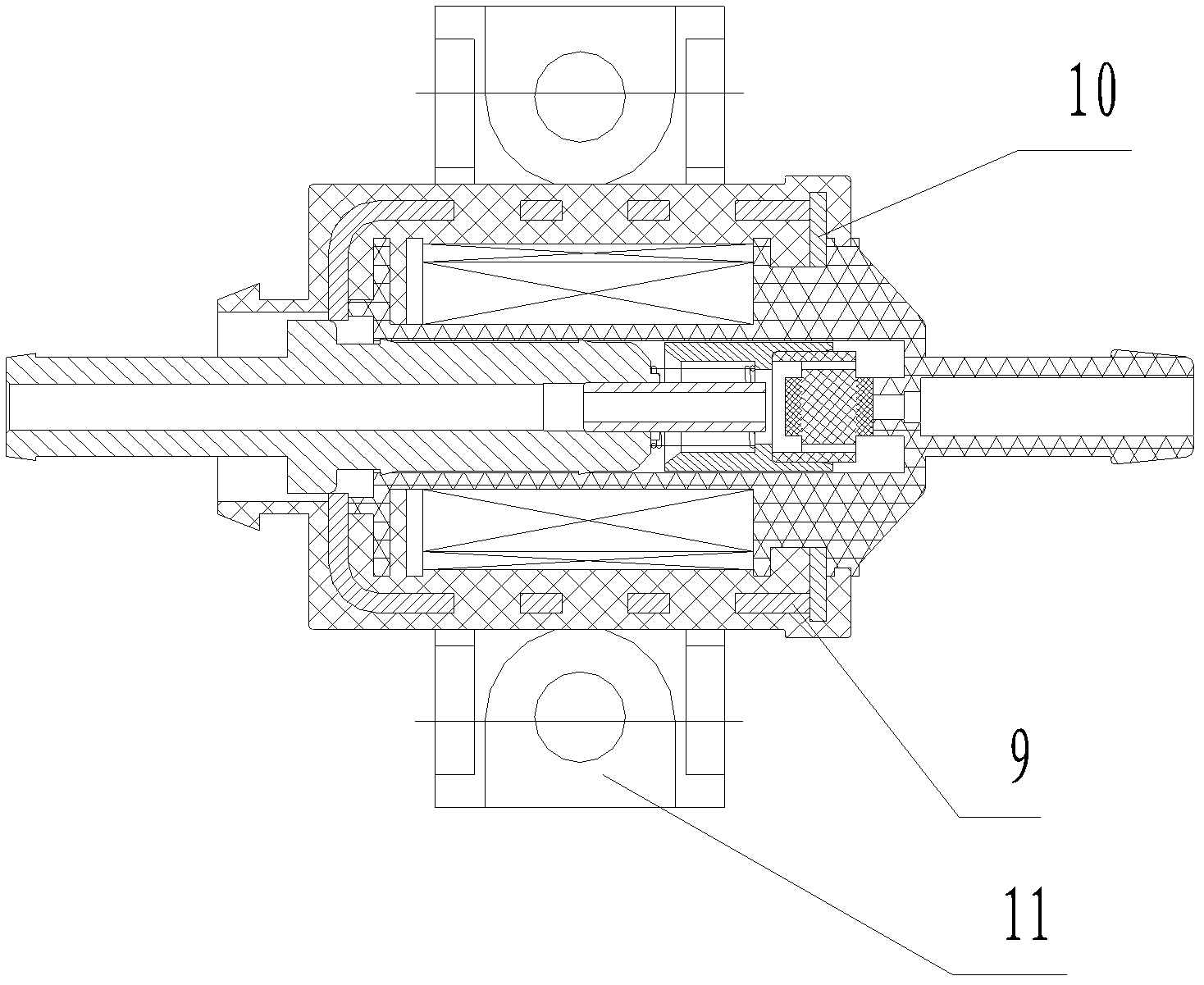

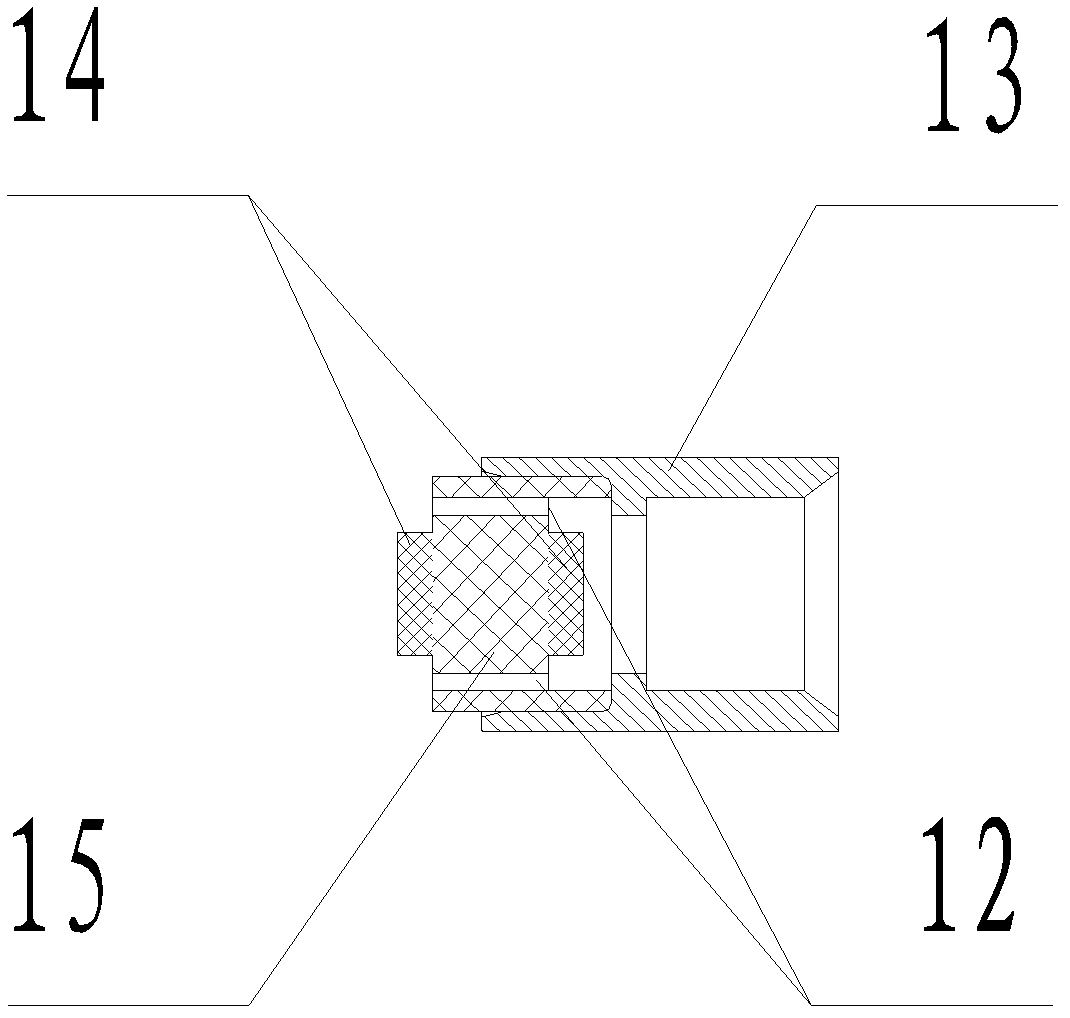

[0016] A positive pressure deflation valve, including a valve body 20, a coil assembly component, a sensitive component 7, and a magnetically conductive component are arranged on the valve body 20, and the coil assembly component includes a coil 1 arranged in the valve body 20, a valve body 20 The second connector 8 and the third connector 2 on one side and the electrode 3 arranged on the other side of the valve body 20, the sensitive part 7 includes a fixed bracket 13 arranged in the valve body 20, and a plastic bracket 15 is arranged in the fixed bracket 13, The fixed bracket 13 is hollow, the plastic bracket 15 is provided with air holes 12, and the magnetically conductive parts include the first joint 4 arranged on the other side of the valve body 20, the magnetically conductive tube 9 and the magnetically conductive plate 10 arranged in the valve body 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com