Novel rotational flow impact boiler and manufacturing method thereof

A manufacturing method and boiler technology, which is applied in the direction of combustion method, combustion type, and combustion with multiple fuels, and can solve problems such as pollution, low NOx emissions, and low burnout efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

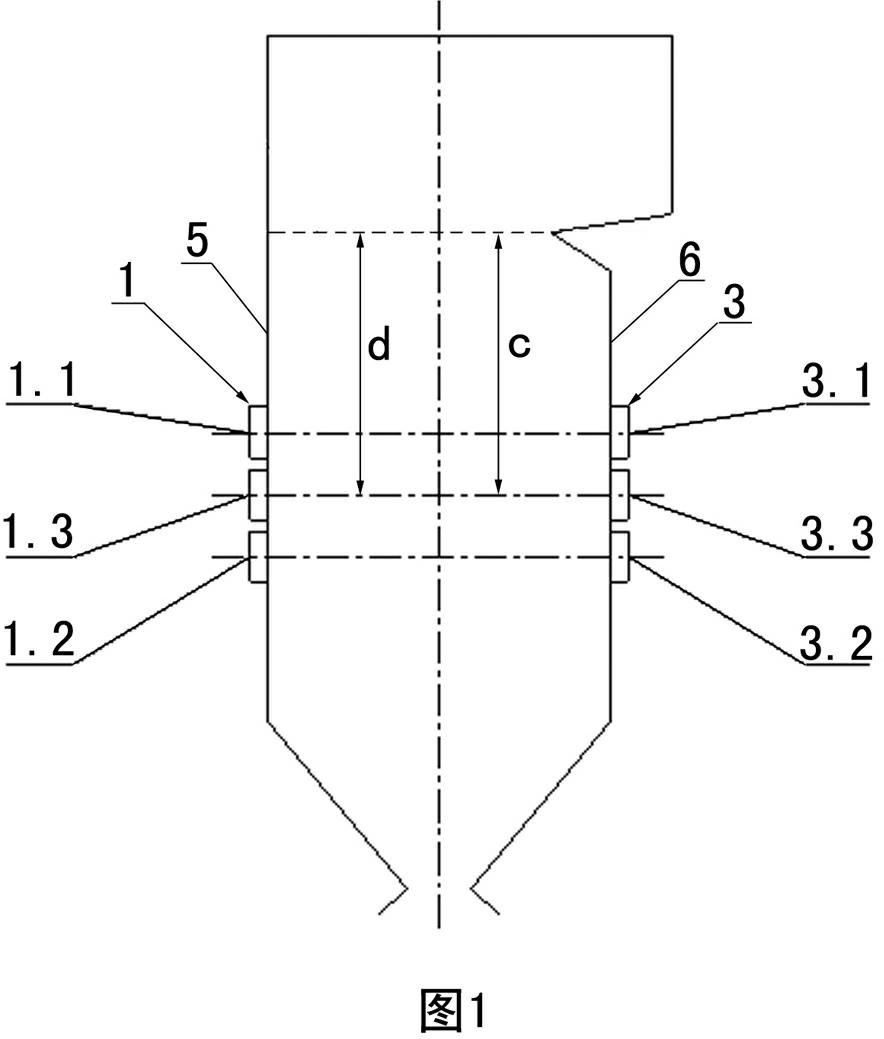

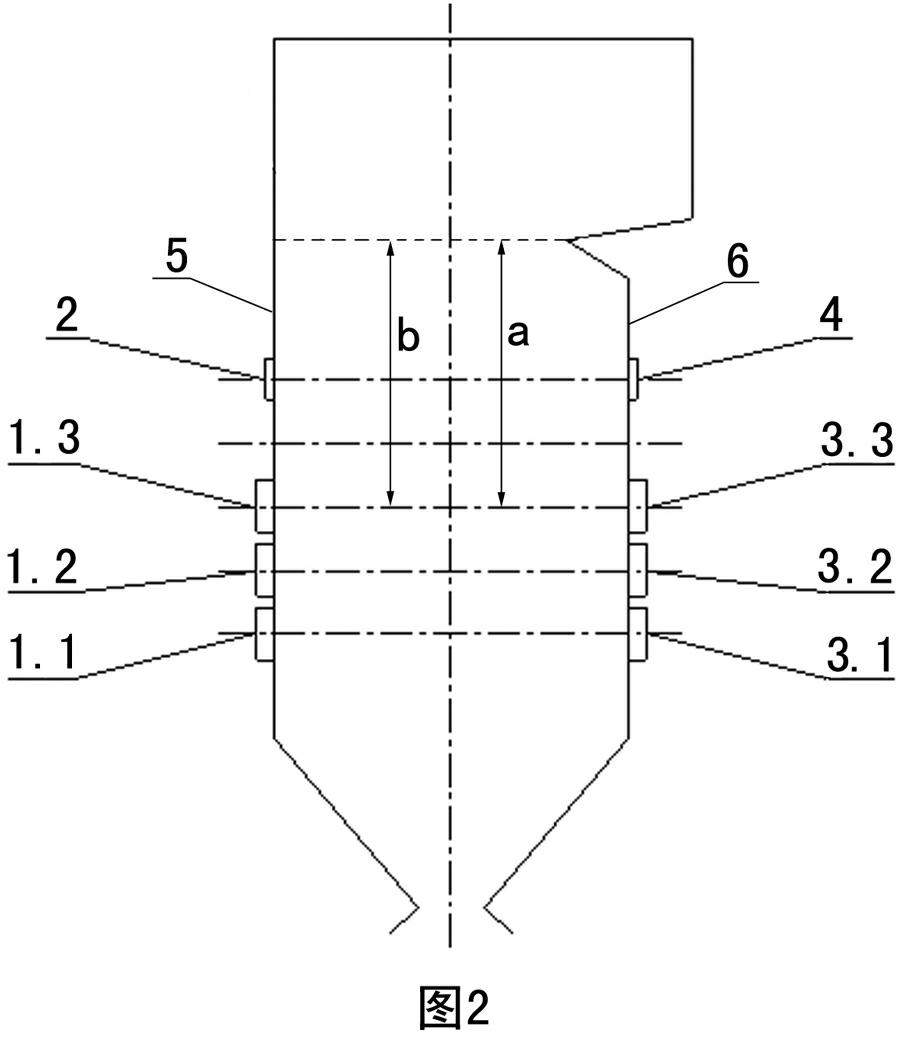

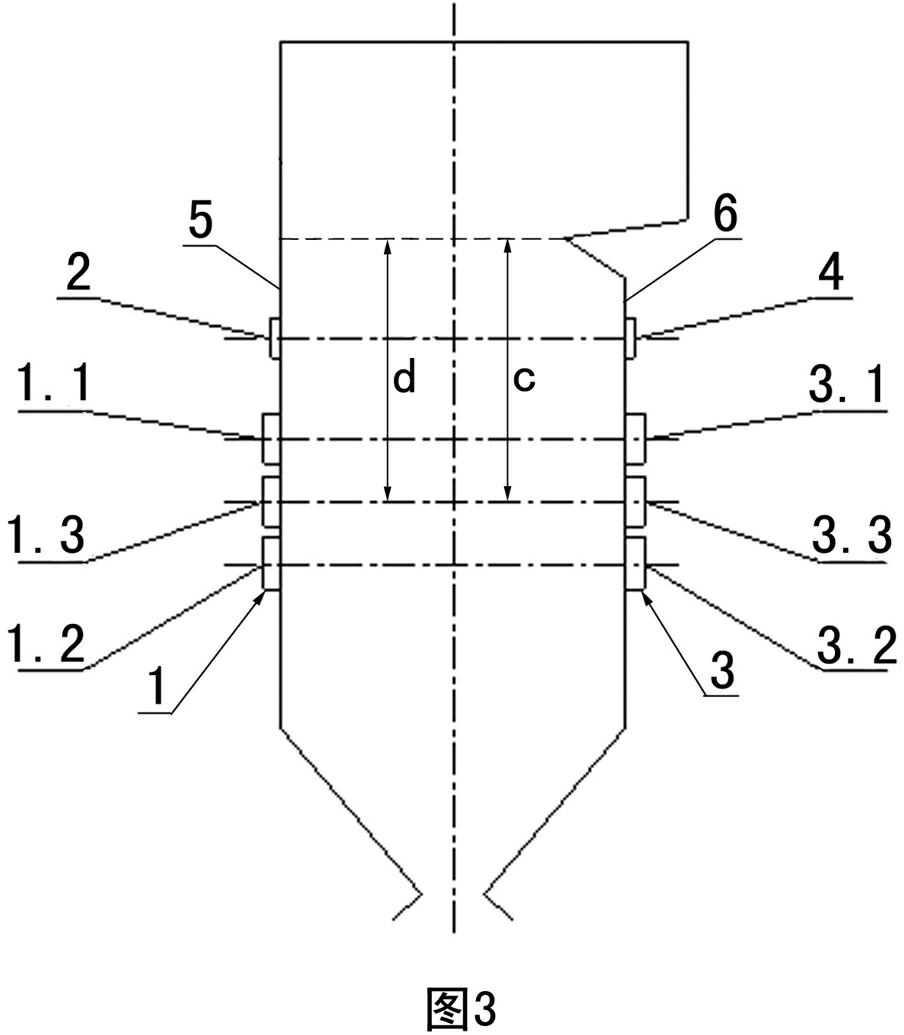

[0036] Embodiment one sees Figure 1-4 , this new type of swirling flow hedge boiler, the front wall 5 of the furnace is provided with three layers of front wall burners 1 and at least one layer of front wall burn-out wind device 2, and the rear wall 6 of the furnace is provided with three layers of rear wall burners 3 and at least one layer of rear wall burn-off air device 4, the distance a from the center line of the uppermost rear wall burner of the new swirl contrast boiler to the bottom of its boiler screen is equal to the rear wall of the traditional swirl contrast boiler of the same size The distance c from the centerline of the burner in the middle layer to the bottom of its boiler panel; the distance b from the centerline of the burner on the uppermost front wall of the new-type swirling flow contrasting boiler to the bottom of its boiler panel is equal to that of a traditional swirling flow contrasting boiler of the same size The distance d from the centerline of the...

Embodiment 2

[0039] Embodiment two see Figure 5 , Figure 7 , Figure 8 , Figure 10 , this new type of swirling flow hedging boiler, the front wall 5 of its furnace is provided with three layers of front wall burners 1 and at least one layer of front wall burn-out wind device 2, and the rear wall 6 of its furnace is provided with two layers of rear wall burners 3 and at least one layer of rear wall burn-out air device 4, the distance a from the centerline of the uppermost rear wall burner in the new swirl contrast boiler to the bottom of the boiler screen is equal to that of a traditional swirl contrast boiler of the same size The distance e from the center line of the burner on the lower layer of the back wall to the bottom of its boiler screen; the distance b from the center line of the burner on the uppermost front wall of the new swirling flow hedge boiler to the bottom of its boiler screen is equal to that of a traditional swirling flow hedge boiler of the same size The distance ...

Embodiment 3

[0042] Embodiment three see Figure 5 , Image 6 , Figure 8 , Figure 9 , this new type of swirling flow hedging boiler, the front wall 5 of its furnace is provided with three layers of front wall burners 1 and at least one layer of front wall burn-out wind device 2, and the rear wall 6 of its furnace is provided with two layers of rear wall burners 3 and at least one layer of rear wall burn-off air device 4, the distance a from the centerline of the uppermost rear wall burner of the new swirl contrast boiler to the bottom of the boiler panel is equal to the front of the traditional swirl contrast boiler of the same size. The distance d from the centerline of the burner in the middle layer of the wall to the bottom of its boiler panel.

[0043] see Figure 5 , Image 6 , one of the manufacturing methods of the above-mentioned novel swirling flow contrast boiler, its steps are as follows: Step 1, prepare a traditional swirling flow relief boiler without an overfire air de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com