Method and device for efficiently oxidizing metal

A metal oxidation, high-efficiency technology, applied in the direction of chemical/physical/physicochemical fixed reactors, etc., can solve the problems of NO gas pollution, complexity, control methods and devices, etc., to speed up the reaction, promote renewal, and fast reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

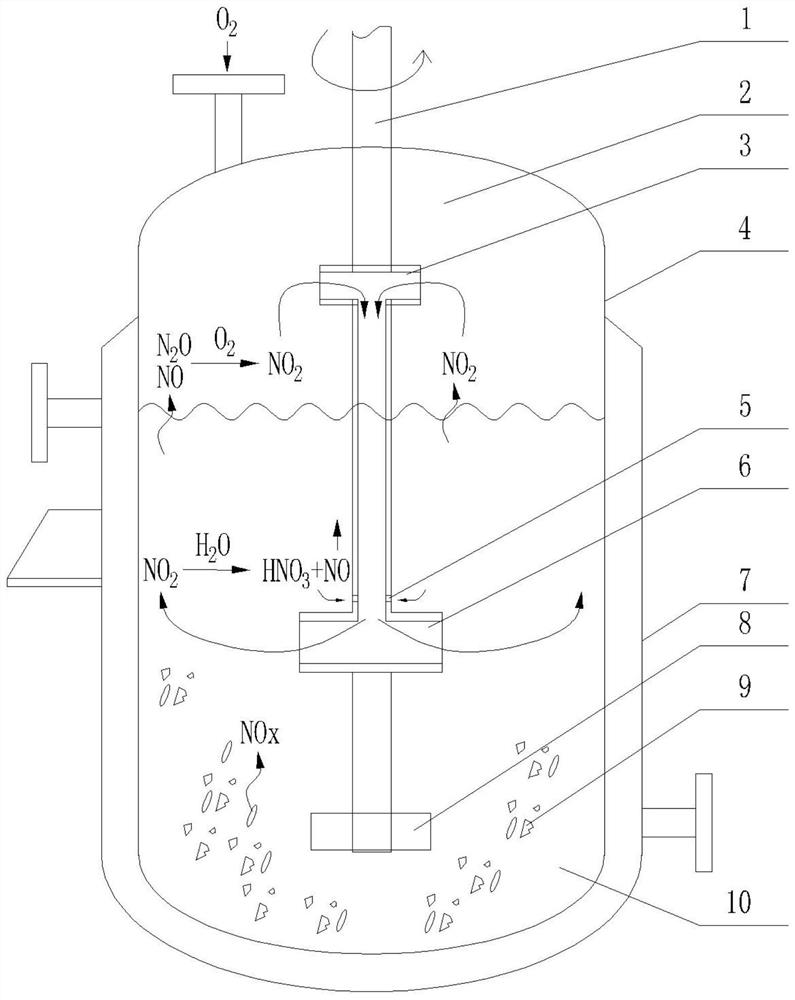

[0035] use as figure 1 device shown, the 1.5m 3 30% nitric acid and 1000kg metallic silver particles are added to 2m 3 In the reactor, in order to improve the utilization rate of nitric acid, about 10% of metallic silver particles is excessive, and the oxygen of 0.5MPa is passed into the reactor top and then closed, and the rotating speed of the hollow stirring shaft 1 is set at 700rpm. The steam in the jacket was heated to 90° C., and after 6 hours of reaction, 1.42 tons of silver nitrate was separated and the utilization rate of nitric acid was 99%.

Embodiment 2

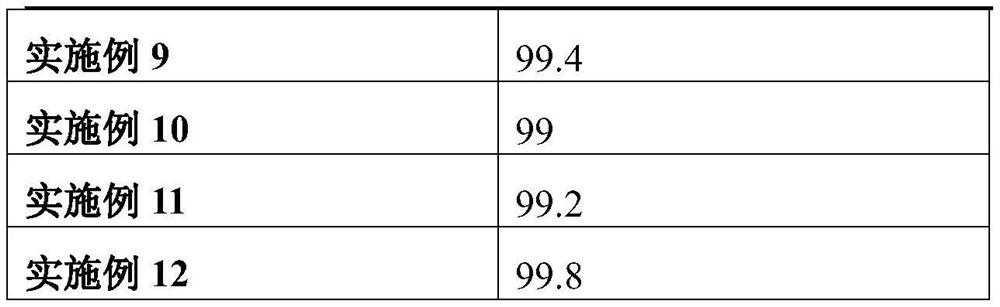

[0039] Referring to Example 1, 355 kg of metal indium particles were used instead of metal silver, and other conditions remained unchanged. After the reaction, 0.839 tons of indium nitrate was obtained, and the utilization rate of nitric acid was 99.3%.

Embodiment 3

[0041] With reference to Example 1, 295kg of metallic copper particles were used instead of metallic silver, and other conditions remained unchanged. After the reaction, 781kg of copper nitrate was obtained, and the utilization rate of nitric acid was 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com