Constant-temperature and constant-humidity production workshop and operation method thereof

A production workshop, constant temperature and humidity technology, applied in the field of guitar processing, can solve the problems of poor air circulation, inability to use wood for storage, stuffy rooms, etc., to achieve the effects of easy recycling, reducing the amount of gas to be dehumidified, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

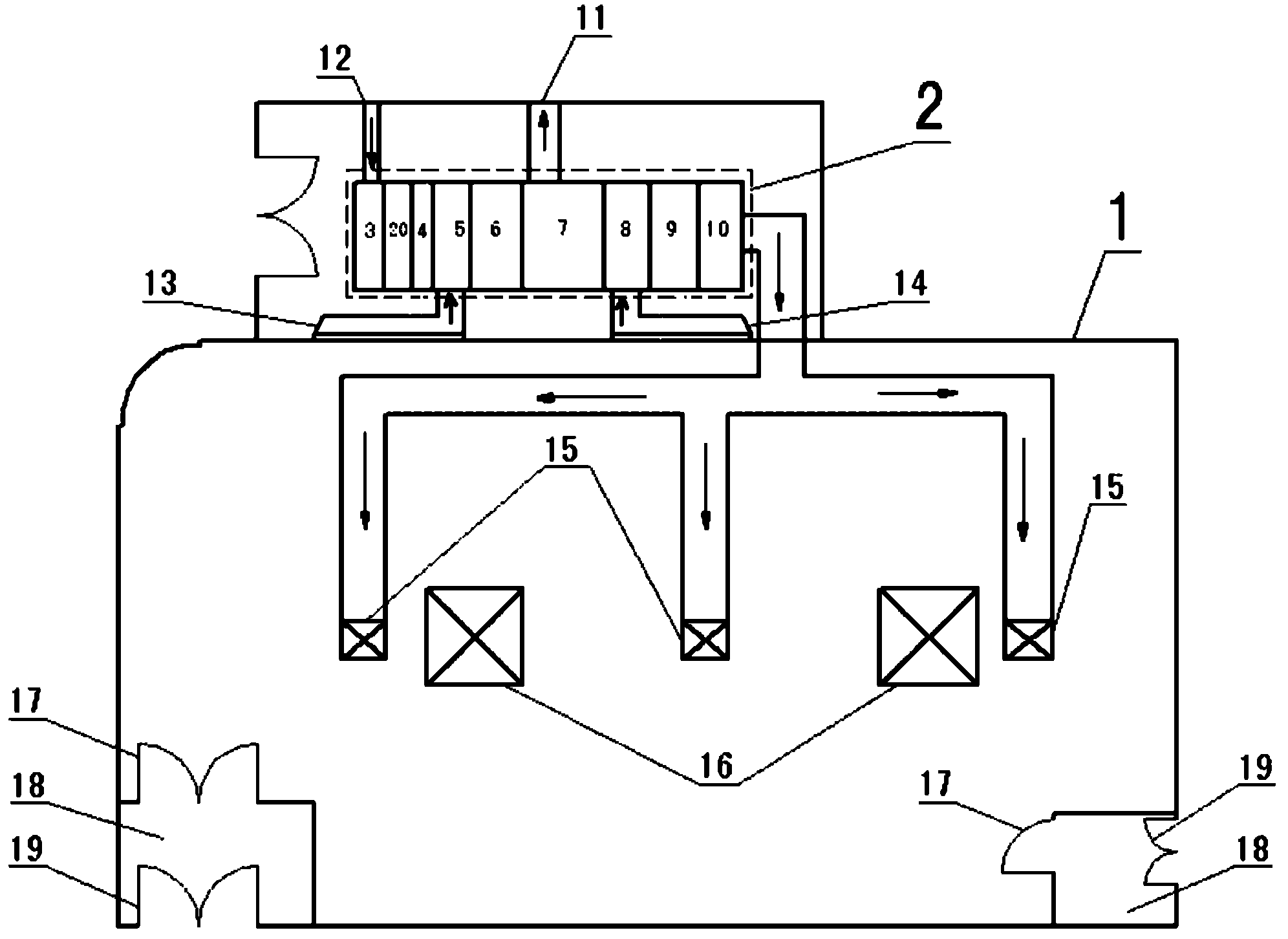

[0030] figure 1 As shown, the constant temperature and humidity production workshop includes: production workshop 1 and dehumidification unit 2.

[0031] Production workshop 1 is a closed factory building with an area of 190 square meters, which has an air outlet, a primary air return port and a secondary air return port. The air outlet is located at the top of the production workshop 1 and is connected to the air outlet unit 10 through the air outlet pipe 15. There are three air outlets here, which are evenly distributed in the production workshop 1 to ensure uniform ventilation in the production workshop. The primary air return port and the secondary air return port are set on the wall of the production workshop 1, the primary air return port communicates with the primary return air unit 5 through the primary return air duct 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com