Condensing gas water heater double inlet air heat exchange device

A gas-fired water heater and heat exchange device technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as low heat exchange efficiency of heat exchangers, high CO content in flue gas, overflow and corrosion of condensed water, etc. , to achieve the effect of low exhaust gas temperature, high heat exchange efficiency and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

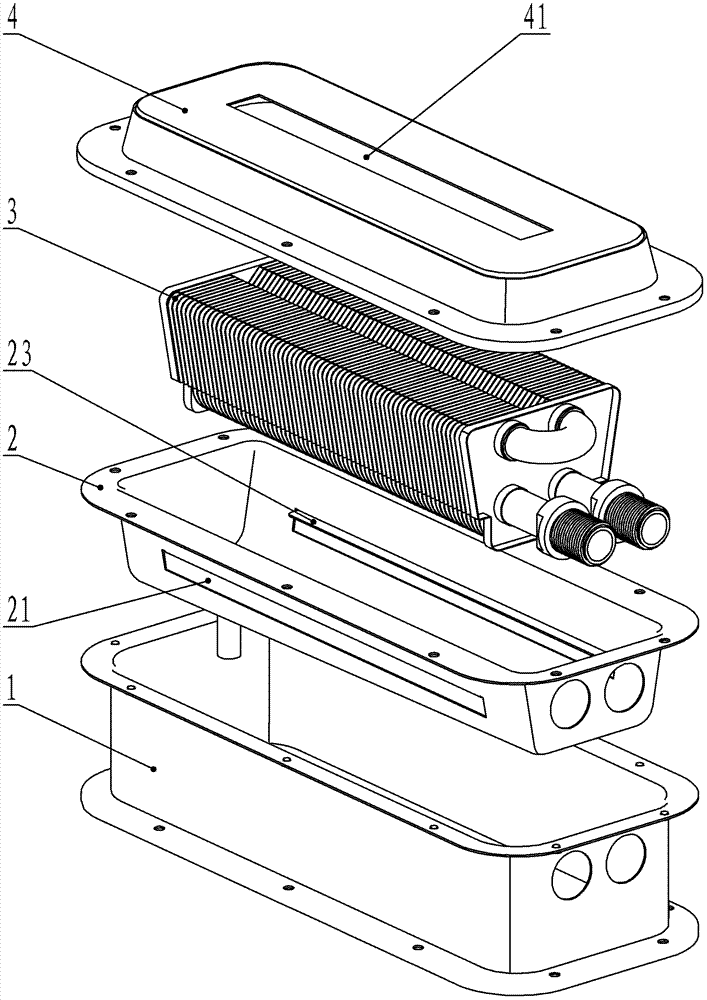

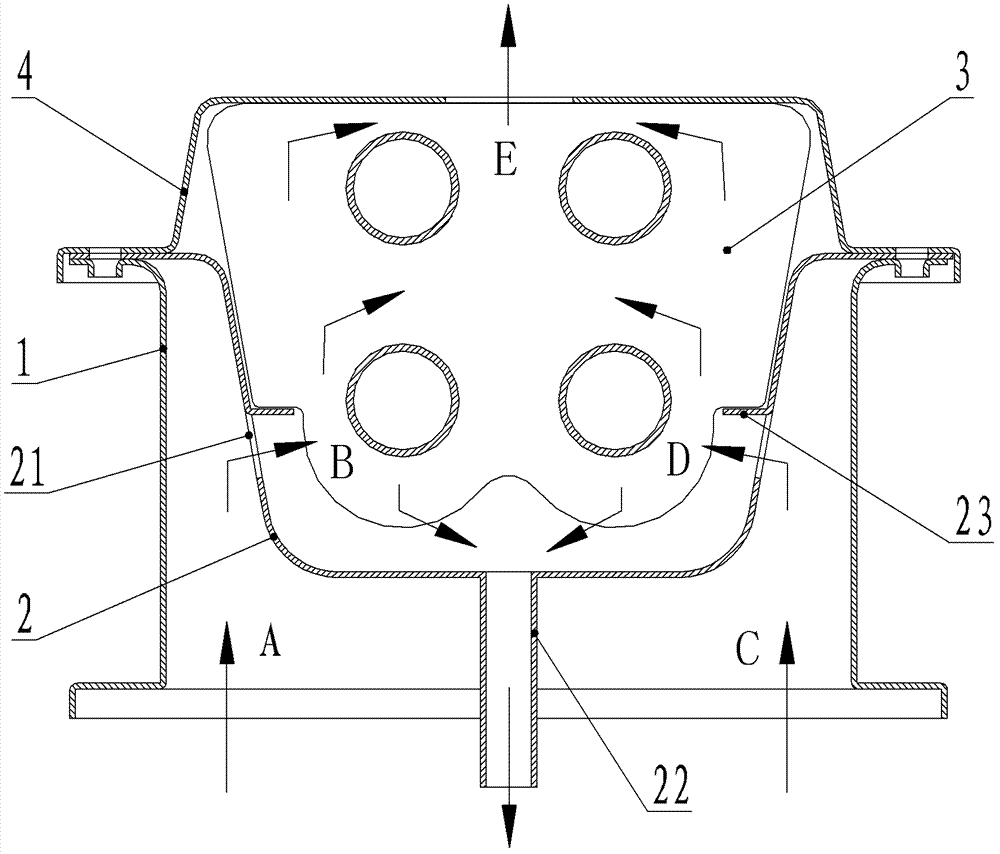

[0022] like Figure 1~2 As shown, the double-inlet heat exchange device for a condensing gas water heater in this embodiment includes a casing 1, a condensed water collection box 2, a condensing heat exchanger 3, and a smoke collection hood 4. The casing 1 is a straight-through structure at both ends, so The side wall of the condensed water collection box 2 is provided with a flue gas inlet 21, and the bottom thereof is provided with a condensed water outlet pipe 22, and the inside of the flue gas inlet 21 is directly above a condensate tube to prevent condensed water from flowing out of the flue gas inlet 21. A water baffle 23, a flue gas outlet 41 is set on the smoke collecting hood 4, the condensed water collection box 2 is set in the shell 1, and the condensed water heat exchanger 3 is set in the condensed water collection box 2 Inside, the fume collecting hood 4 is buckled on the condensed water collecting box 2 and encloses the condensing heat exchanger 3 inside.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com