Air leakage detection method of condenser

An air detection and condenser technology, which is applied in the detection field, can solve the problems of increased end difference and reduced heat transfer performance of the condenser, and achieves the effect of wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

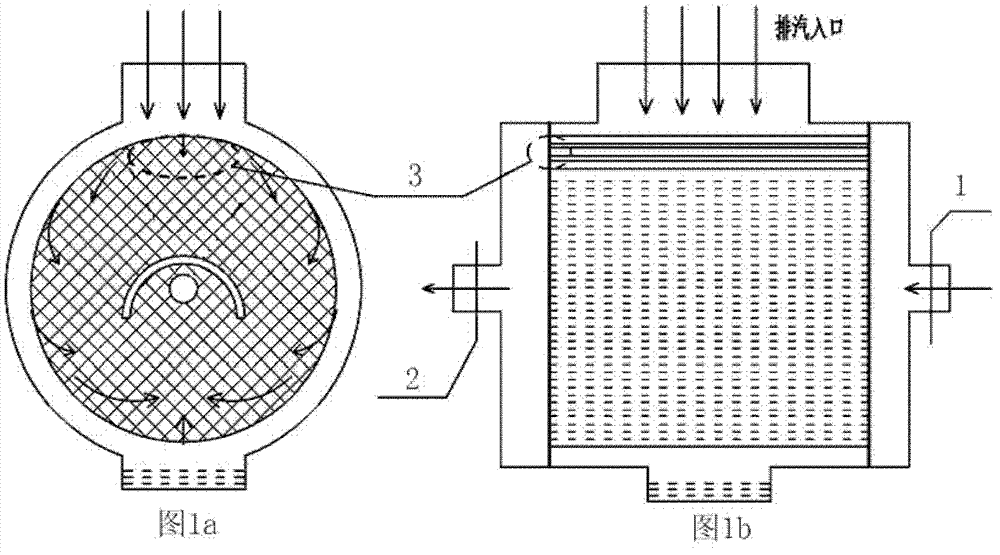

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

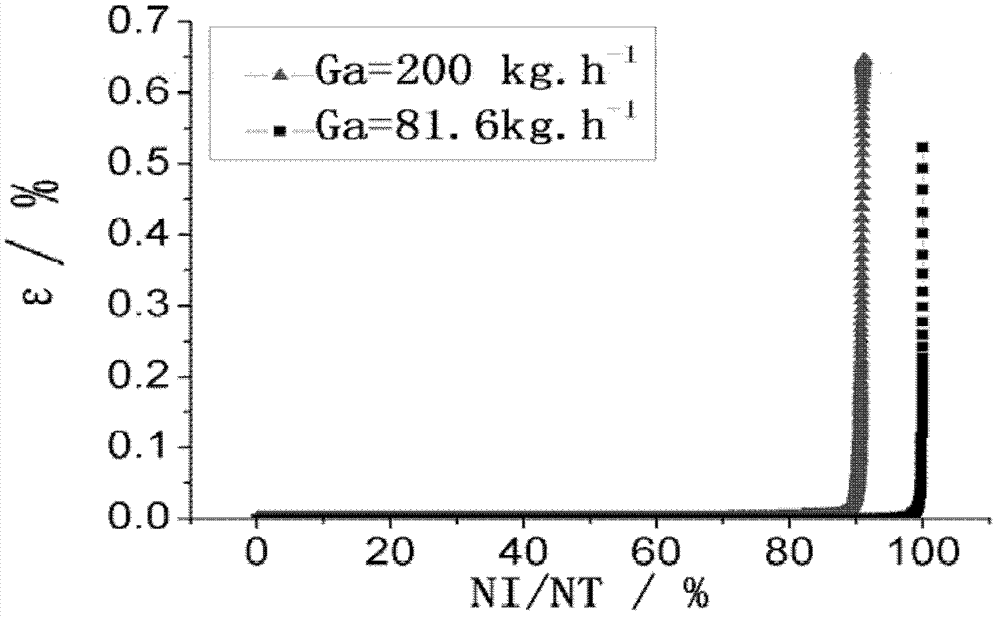

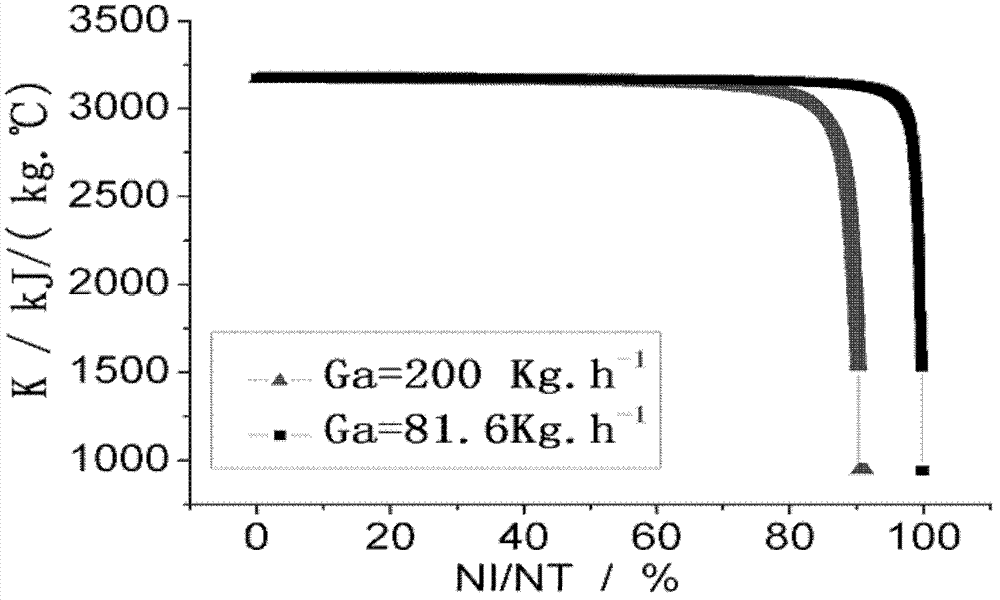

[0026] Figure 2-4 It is the change law of the relative content of air in the steam, heat transfer coefficient and temperature rise of circulating water in heat exchange tubes during the condensation process obtained by numerical simulation at the same heat load of a supercritical 600MW unit condenser, under two different air leakage amounts . It can be seen from the figure that in most areas, the relative content of air in the steam is very low, and its heat transfer coefficient and temperature rise of circulating water remain constant; after a certain critical point, the relative content of air increases sharply, while The heat transfer coefficient and the temperature rise of the circulating water drop sharply. The position where the critical point appears is related to the amount of air leakage, the larger the amount of air leakage, the earlier this poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com