System and method for DCS (distributed control system) hardware configuration based on Excel

An excel and software system technology, applied in the field of DCS hardware configuration system based on Excel sheets, can solve the problems of consuming a lot of time and resources, waste of time and resources, lack of interfaces, etc., to simplify the operation of DCS hardware configuration and save Effects of time and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

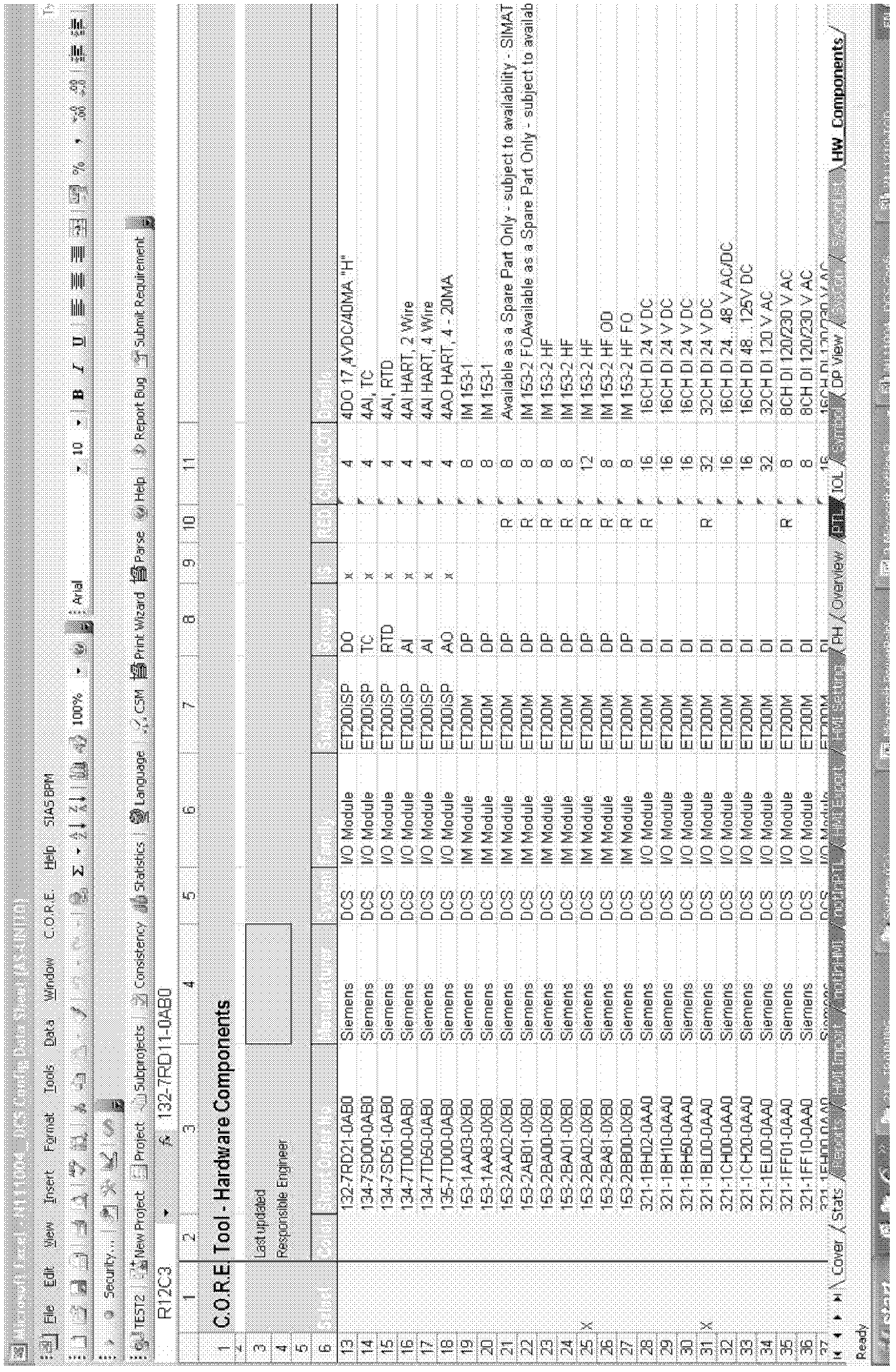

[0026] Aiming at the technical problems in the prior art, the present invention utilizes the VBA interface of the Excel software to develop the DCS hardware configuration system based on the Excel sheet. In this system, DCS engineers can realize functions such as automatically arranging various hardware devices and automatically assigning input / output point addresses to card channels according to DCS project user data and self-defined rules, so as to complete the DCS system in the Excel form hardware configuration. The results are presented to users in the form of intuitive graphics and tables, which support further manual adjustments, and all hardware configuration information can be directly saved as hardware configuration files that can be recognized by the DCS software system, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com