Method for arranging bar code type capacitive electrode plate in electrode of alkaline cell as well as mixed negative electrode

A technology of alkaline battery and battery negative electrode, applied in the direction of alkaline battery electrode, capacitor electrode, hybrid battery, etc., can solve the problems of obtaining the best process conditions, long life of the pole piece, low internal resistance and high strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

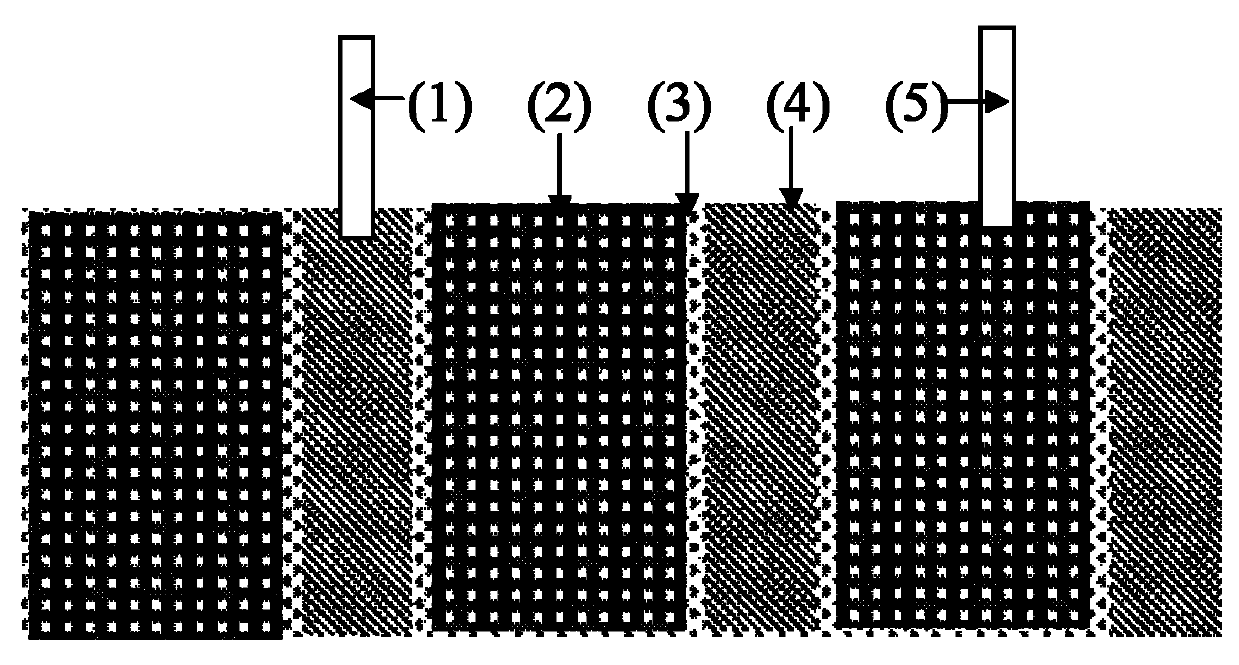

Method used

Image

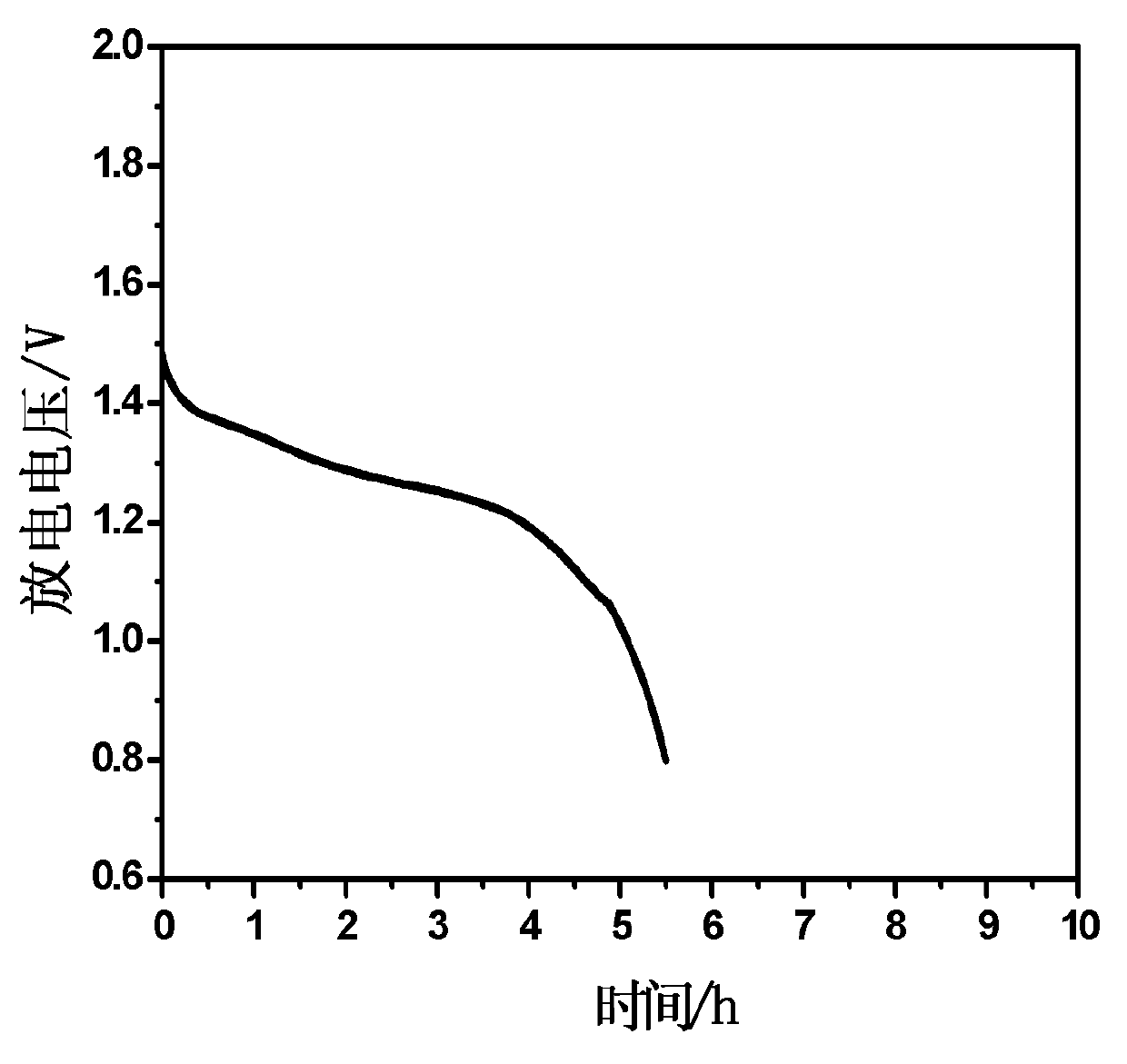

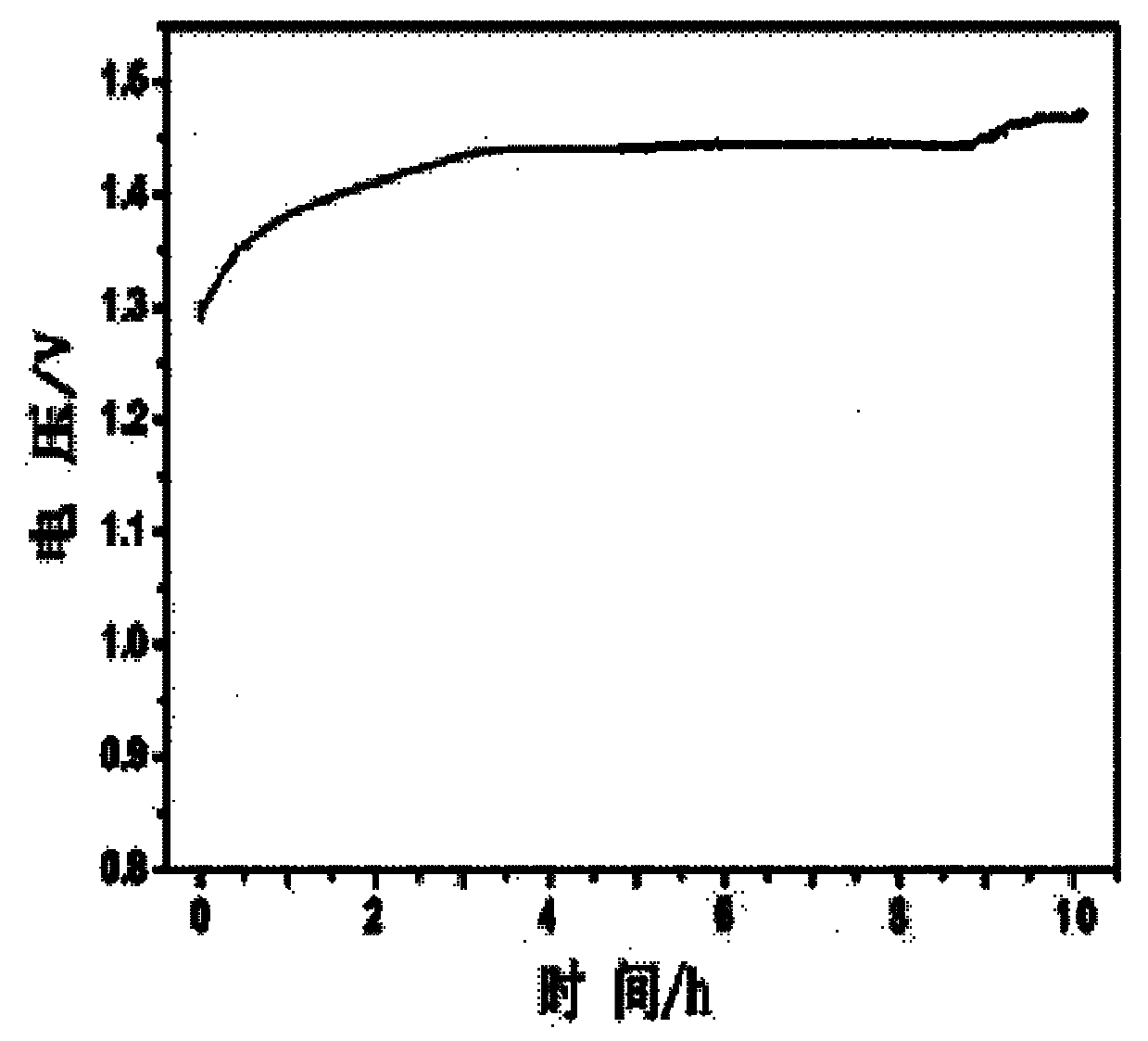

Examples

Embodiment 1

[0070] The first step, material selection and preparation:

[0071] (1) Negative electrode current collector: as the current collector of the strip-shaped capacitor pole piece and as the current collector of the strip-shaped battery negative pole piece, the foamed nickel commodity in the battery material is selected, and the foamed nickel used as the capacitor pole piece current collector The thickness, ratio The nickel foam used for the negative electrode collector of the strip battery is 0.2mm thicker;

[0072] (2) Scratch paint for strip-shaped capacitor pole piece: 600 mesh activated carbon powder, 600 mesh graphite powder and polytetrafluoro emulsion with a solid content of 52 wt%. The three are mixed according to the ratio of 90wt%, 7wt% and 3wt% for later use; the sum of the three weight percentages constitutes 100wt%;

[0073] (3) Strip battery negative plate scraping coating: 250 mesh-300 mesh AB 5Type hydrogen storage alloy powder, the method to obtain alloy powder...

Embodiment 2

[0094] The difference with embodiment 1 is:

[0095] ① The proportional relationship between the width of the negative plate of the strip battery and the width of the strip capacitor is 1:1.

[0096] ②The density is 1.31g / cm 3 Potassium hydroxide-sodium hydroxide-lithium hydroxide ternary lye is used as the battery electrolyte and 2.2ml is added to the AA-type cylindrical battery;

[0097] All the other steps and conditions are the same as in Example 1.

Embodiment 3

[0099] The difference with embodiment 1 is:

[0100] ① The proportional relationship between the width of the negative plate of the strip battery and the width of the strip capacitor is 1.5 to 1;

[0101] ②The number of solder joints in the splicing area satisfies 3+X, and the value of X in the design specification is determined to be 1;

[0102] ③The density is 1.31g / cm 3 Potassium hydroxide-sodium hydroxide-lithium hydroxide ternary lye is used as the battery electrolyte and 2.5ml is added to the AA-type cylindrical battery;

[0103] All the other steps and conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com